Resource utilization and treatment method of alkynol wastewater

A treatment method and resource recovery technology, which is applied in the field of resource utilization and treatment of acetylenic alcohol wastewater, can solve the problems of organic impurities in wastewater that cannot be treated, and achieve the effect of resource recovery and zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

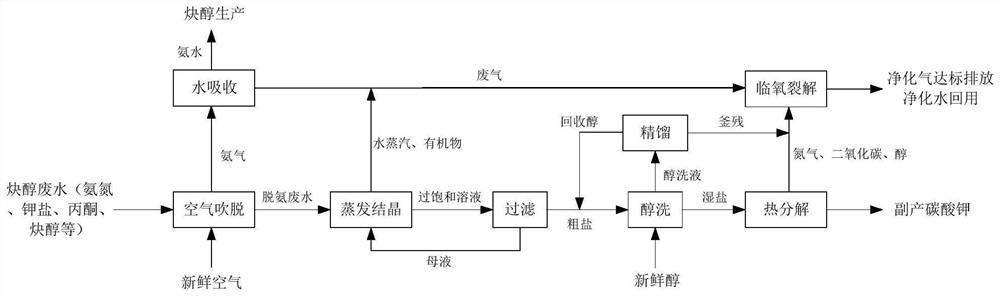

Image

Examples

Embodiment 1

[0043] Alkyne alcohol wastewater composition: COD value is 45960mg / L, ammonia nitrogen value is 18051mg / L, the content of potassium carbonate is 25.2wt.%, the content of potassium bicarbonate is 0.5wt.%, the content of organic matter is 1.53wt.%, the rest is moisture.

[0044] Such as figure 1 , a resource utilization and treatment method of acetylenic alcohol wastewater, the steps are as follows:

[0045] Step (1), pump the above-mentioned acetylenic alcohol wastewater into the stripping tower, the waste water circulates from top to bottom with a flow rate of 1500kg / h, and the stripping air takes a gas volume of 120m 3 / h backflushing from bottom to top; the stripping tower discharges the ammonia blown out by the air, enters three ammonia gas absorption towers connected in series, and uses water as the absorption liquid for three-stage water absorption, and each stage of the absorption tower The absorption liquid is independently circulated and absorbed, and the circulation...

Embodiment 2

[0051] Alkyne alcohol wastewater composition: COD value is 62198mg / L, ammonia nitrogen value is 25043mg / L, the content of potassium carbonate is 31.6wt.%, the content of potassium bicarbonate is 0.3wt.%, the content of organic matter is 2.07wt.%, the rest is moisture.

[0052] A resource utilization and treatment method of acetylenic alcohol wastewater, the steps are as follows:

[0053] Step (1), pump the above-mentioned acetylenic alcohol wastewater into the stripping tower, the waste water circulates from top to bottom with a flow rate of 1800kg / h, and the stripping air takes a gas volume of 144m 3 / h backflushing from bottom to top; the stripping tower discharges the ammonia blown out by the air, enters three ammonia gas absorption towers connected in series, and uses water as the absorption liquid for three-stage water absorption, and each stage of the absorption tower The absorption liquid is independently circulated and absorbed, and the circulation flow rate of the ab...

Embodiment 3

[0059]Composition of acetylenic alcohol wastewater: COD value is 52080mg / L, ammonia nitrogen value is 20619mg / L, potassium carbonate content is 28.1wt.%, potassium bicarbonate content is 0.4wt.%, organic matter content is 1.74wt.%, and the rest is water.

[0060] A resource utilization and treatment method of acetylenic alcohol wastewater, the steps are as follows:

[0061] Step (1), pump the above-mentioned acetylenic alcohol wastewater into the stripping tower, the waste water circulates from top to bottom with a flow rate of 2000kg / h, and the stripping air takes a gas volume of 160m 3 / h backflushing from bottom to top; the stripping tower discharges the ammonia blown out by the air, enters three ammonia gas absorption towers connected in series, and uses water as the absorption liquid for three-stage water absorption, and each stage of the absorption tower The absorption liquid is independently circulated and absorbed, and the circulation flow rate of the absorption liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com