Carbon aerogel composite structure, composite filter element, preparation methods of the carbon aerogel composite structure and the composite filter element and application of the carbon aerogel composite structure and the composite filter element

A carbon aerogel, composite structure technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve the effects of excellent adsorption performance, high purification efficiency, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

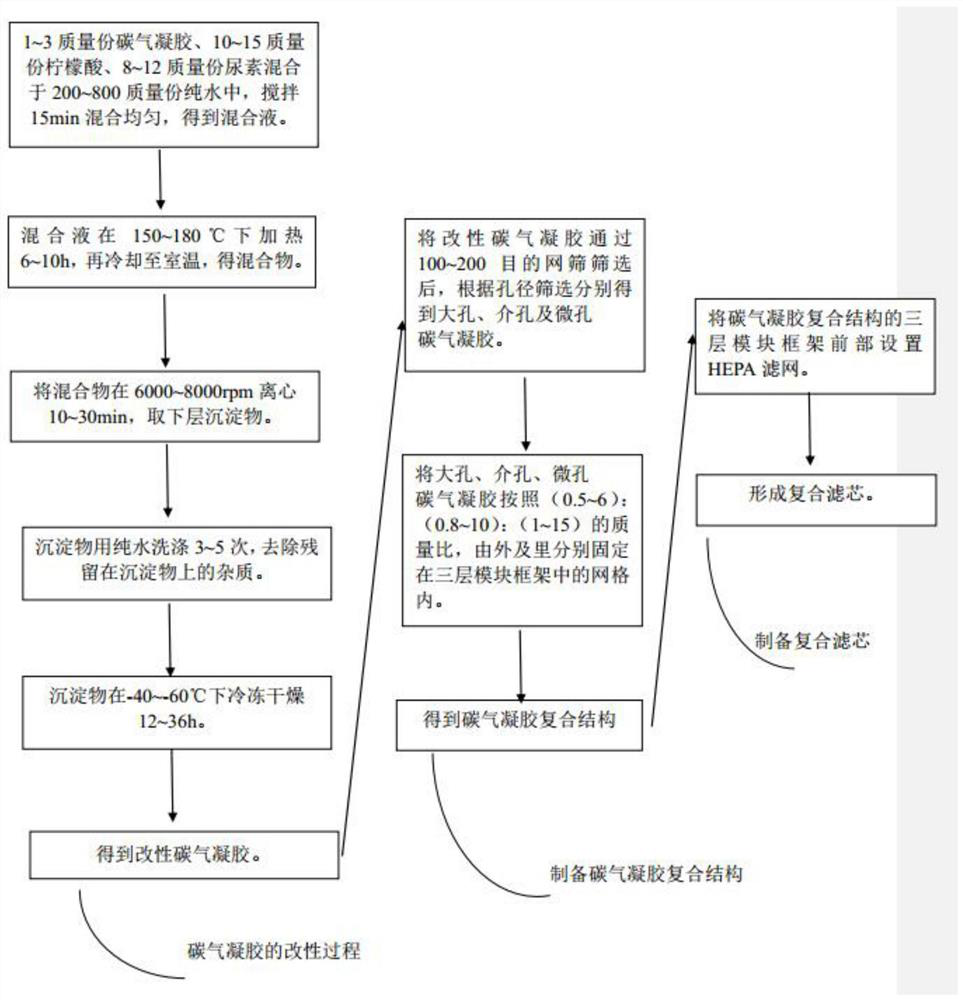

[0044] In this example, carbon aerogel, citric acid, urea, and pure water are used as raw materials to prepare a carbon aerogel composite structure. The specific steps are as follows:

[0045] (1) 0.1g of carbon aerogel, 1g of citric acid and 0.8g of urea are mixed and dissolved in 20g of pure water, stirred for 15min, and carbon aerogel, citric acid, and urea are evenly dispersed in pure water to obtain mixed solution;

[0046] (2) Heating the mixed solution in (1) at 160° C. for 8 h, and then cooling to room temperature to obtain the mixture;

[0047] (3) Centrifuge the mixture in (2) at a speed of 7000rpm for 25min, and remove the lower sediment after centrifugation;

[0048] (4) Wash the precipitate in (3) 4 times with pure water to remove impurities remaining on the precipitate;

[0049] (5) Freeze-dry the precipitate in (4) at -60°C for 24 hours to obtain a modified carbon aerogel;

[0050] (6) Pass the carbon aerogel in (5) through a 100-mesh sieve to obtain uniform ...

Embodiment 2

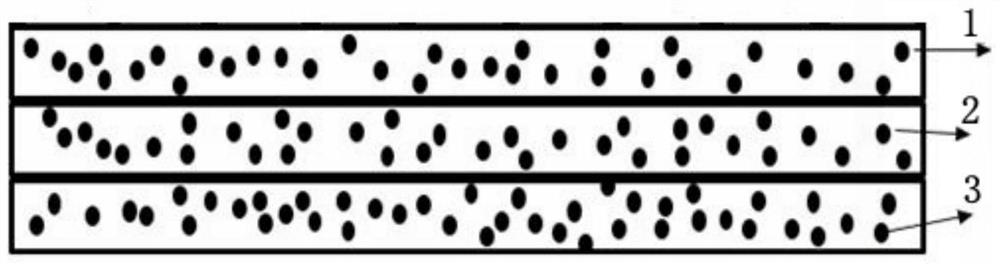

[0052] The macroporous, mesoporous and microporous carbon aerogels in Example 1 are in the range of mass ratio (0.5~6):(0.8~10):(1~15), for example: 5:8:10, 1:2:4, 1:3:3, 1:3:5, 1:4:2, 1:4:3, 2:2:3, 2:2:5, 2:3:2, 2: Mass ratios of 3:3, 2:3:4, 3:2:2, 4:7:8 or 6:10:15 are respectively fixed in the grid in the three-layer module frame from the outside and inside, respectively Carbon airgel composite structures with different mass ratios were obtained.

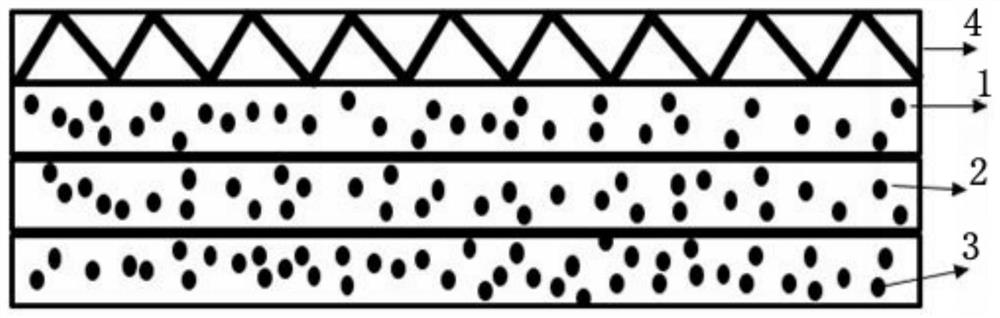

[0053] Further, as figure 2 As shown, the three-layer module frame equipped with carbon airgel is detachably installed in a composite filter element frame, and a HEPA filter is arranged at the front of the macroporous carbon airgel outer layer 1 of the three-layer module frame. Net 4, the thickness of the filter net is 5-8cm, and the composite filter element is obtained.

Embodiment 3

[0055] In order to explore the effect of the carbon airgel composite structure prepared by the method of the present invention to adsorb toluene vapor, this example selects any carbon airgel composite structure (excluding the module frame) prepared in Example 1, according to GBT12496. 5-1999 (refer to the wood activated carbon test method) method to test it. The specific plan is as follows:

[0056] (1) Weigh the obtained carbon airgel composite structure (excluding the module frame) with a mass of m (5g) as the adsorption material, add it to a quartz glass box dried to constant weight, and weigh the quartz glass with the adsorption material bin and record its mass as m 0 .

[0057] (2) Connect the quartz glass box equipped with adsorption material into the test device, keep the flow rate of the mixed gas containing toluene vapor at 1000±10mL / min, set the ambient temperature at 25±2°C, and start the test. At 0.5h, 1h, 2h, 3h, 4h after the start of the test, weigh the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com