Transformer core structure and power transformer

A technology for power transformers and steel, applied in transformer/inductor cooling, transformer/inductor noise damping, transformer/inductor magnetic cores, etc., can solve the problems of uncontrollable transformer capacity and large load loss, and avoid cracking Or microscopic cracks, reduce loss, reduce the effect of voltage power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

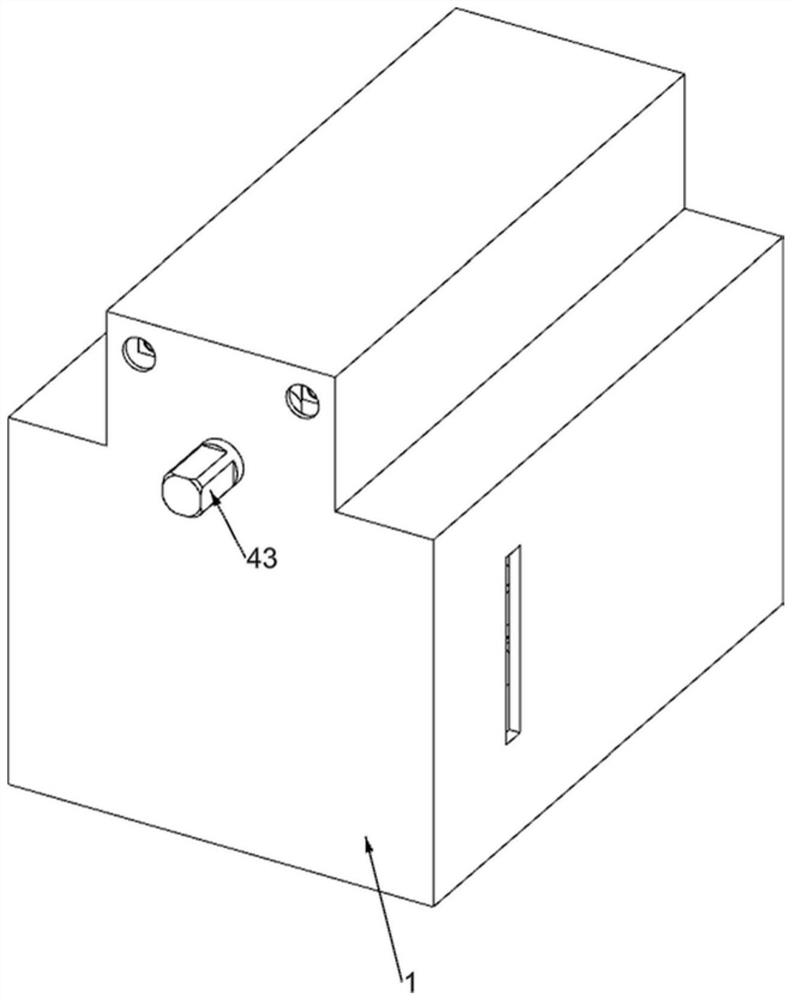

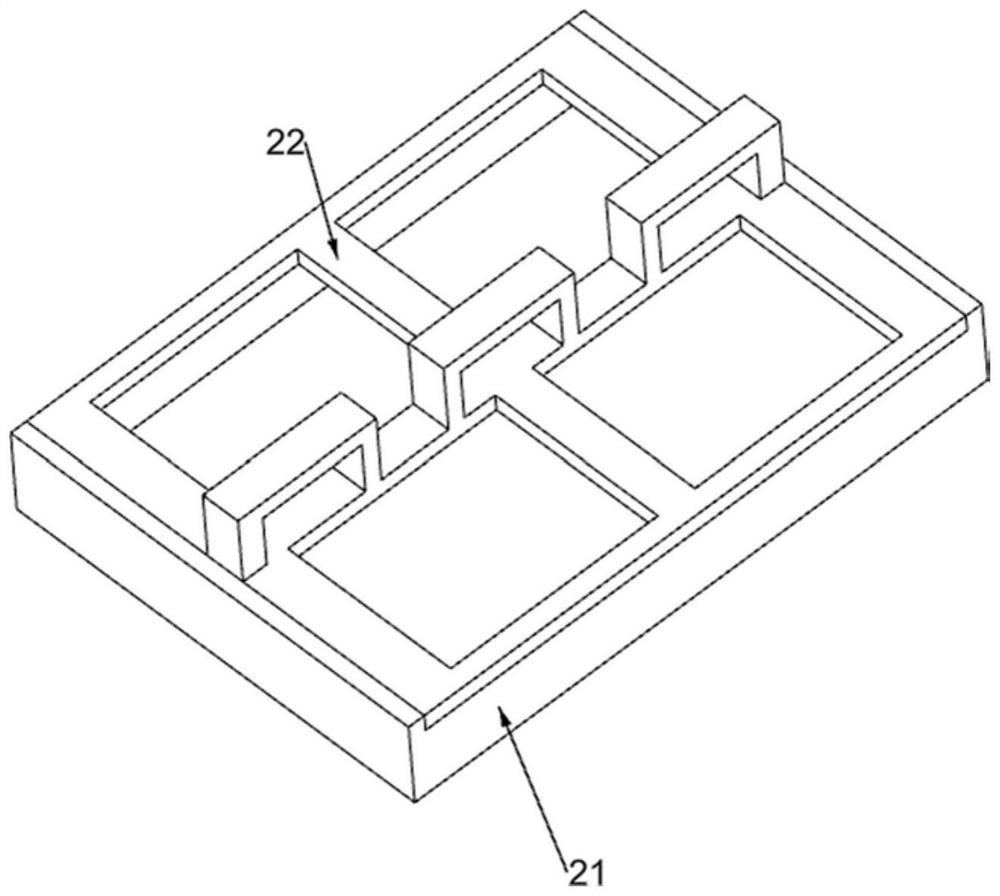

[0042] A transformer core structure and power transformer, such as Figure 1 、 Figure 2 、 Figure 3 、 Figure 4 、 Figure 5 、 Figure 6 、 Figure 7 、 Figure 8 、 Figure 9 、 Figure 10 、 Figure 11 、 Figure 17 and 18 Shown, comprising a housing 1, a bottom plate chamber 21, a slotted support frame 22, a pressure transformer member 3 and a regulating member 4, the shell 1 is fixedly installed with a bottom plate chamber 21, the bottom plate chamber 21 is fixedly installed with a slotted support frame 22, the pressure transformer member 3 is provided on the slotted support frame 22, the pressure change member 3 is provided with a regulating member 4.

[0043] The voltage transformer member 3 includes a silicon steel chip 31, a main coil 32, a separator plate 33, a secondary coil one 34, a secondary coil two 35, a secondary coil three 36, a terminal block 37 and a silicon steel terminal post 38, the slotted support frame 22 distributed is provided with three stacks of silicon steel chips 31, ...

Embodiment 2

[0048] On the basis of Example 1, e.g., Figure 7 、 Figure 8 and Figure 9 Shown, further comprising an oil injection member 5, the open hole support frame 41 is provided with an oil injection member 5, the oil injection member 5 comprises a P-type slotted frame 51, solenoid valve 52, oil guide 53, sector gear 54, L type rack rack 55, first reset spring 56, sliding tooth block 57, a second reset spring 58 and a magnetic valve switch 59, the open hole support frame 41 is fixed on two P type slotted frame 51, the P type slotted frame 51 above the solenoid valve 52, The electromagnetic valve 52 is connected to the oil guide pipe 53, the oil guide pipe 53 is connected to the two separators 33, the sector gear 54 is fixed to the lead screw 42, the P-type slotted rack 51 is vertically sliding connected to the L-type rack rack 55, the L-type rack rack 55 and the P-type slotted rack 51 is connected to the first reset spring 56, the L-type rack rack 55 above the sliding tooth block 57, the ...

Embodiment 3

[0052] On the basis of Example 2, e.g., Figure 10 、 Figure 11 、 Figure 12 、 Figure 13 、 Figure 14 、 Figure 15 、 Figure 16 and Figure 17 Shown, further comprising a variable speed cooling member 6, the bottom plate chamber 21 side is provided with a variable speed cooling member 6, the variable speed cooling member 6 includes a fixed support block 61, servo motor 62, fan cover 63, glass fiber reinforced plastic fan 64, transmission gear 65, slotted bushing 66, sliding rod 67, first homing spring 68, sliding gear 69, second homing spring 610, elastic steel belt 611, L-type slotted frame 612, with rod curved sliding sleeve 613 and wedge push bar 614, The bottom plate chamber 21 is fixedly mounted on one side of the fixed support block 61, the fixed support block 61 is fixedly mounted with a servo motor 62, the slotted support frame 22 is symmetrically fixed mounted with a fan cover 63, the fan cover 63 is fixed with a terminal block 37, the fan cover 63 is rotated connected to a gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com