Eight-valve piston type dynamic flow measurement standard device and measurement method

A dynamic flow, valve piston technology, used in measuring devices, testing/calibrating devices, liquid/fluid solids measurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

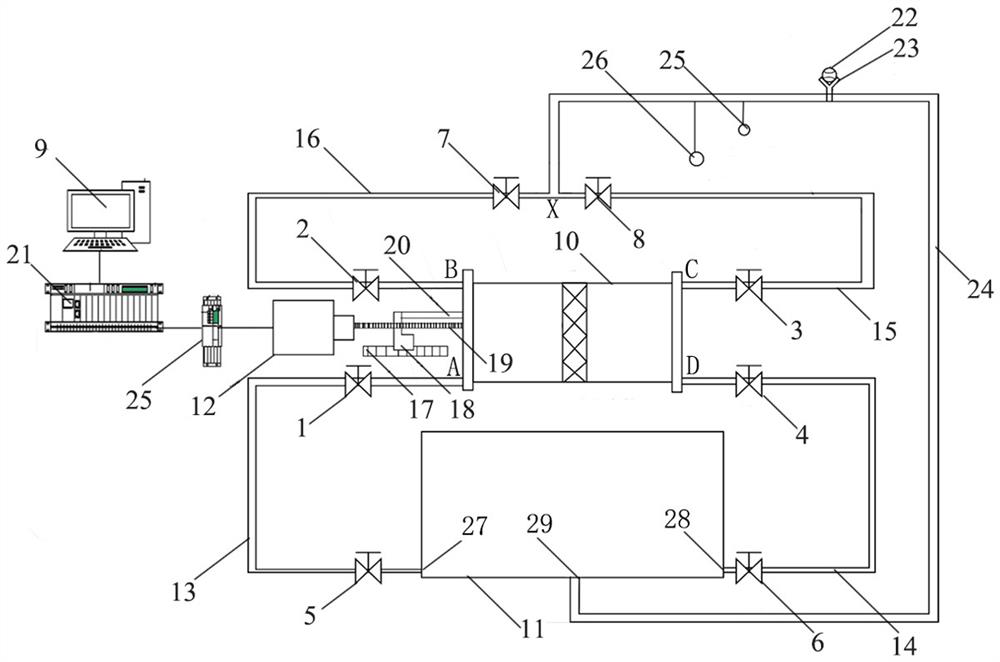

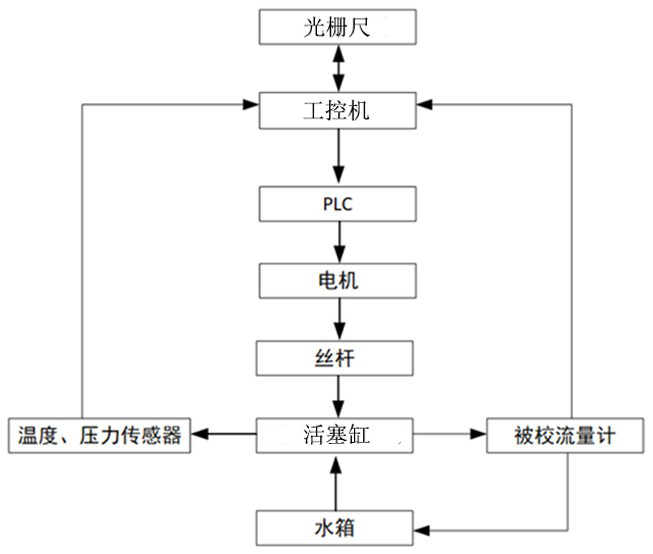

[0041] Such as figure 1 As shown, the present invention includes industrial computer 9, PLC21, servo drive, servo motor 12, leading screw 19, grating ruler 17, piston cylinder 10, water tank 11, pulsating flow pipeline network, calibration pipeline 24, the first valve 1, The second valve 2 , the third valve 3 , the fourth valve 4 , the fifth valve 5 , the sixth valve 6 , the seventh valve 7 , the eighth valve 8 , the pressure sensor 26 and the temperature sensor 25 . The pulsating flow pipeline network is connected between the piston cylinder 10, the water tank 11 and the calibration pipeline 24, and is used to make the pulsating flow always exist in the calibration pipeline 24 where the flowmeter 22 to be tested is located. The pulsating flow pipeline network includes a first water outlet pipe 15, a second water outlet pipe 16, a first water return pipe 13, a second water return pipe 14,

[0042] Among them, the industrial computer 9, the flowmeter 22 to be tested, the motor...

Embodiment 2

[0053] An eight-valve piston type dynamic flow measurement method, such as figure 1 and figure 2 shown, including the following steps:

[0054] a, prepare the eight-valve piston type dynamic flow metering standard device in embodiment 1, be provided with pressure sensor 26 and temperature sensor 25 on described calibration pipeline 24, flow through the liquid temperature and pressure information of tested flow meter 22 Real-time detection and acquisition.

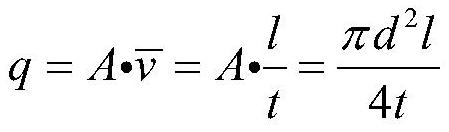

[0055] b. The industrial computer 9 sends a pulse signal to the motor 12, and the motor 12 controls the nut 18 on the lead screw 19 to drive the piston rod 20 to move to the right. At the same time, the industrial computer 9 records and controls the displacement of the grating ruler 17 on the nut 18 in real time. The first valve 1, the third valve 3, the fifth valve 5 and the eighth valve 8 are opened, the second valve 2, the fourth valve 4, the sixth valve 6 and the seventh valve 7 are closed, and the extruded from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com