Metal wire feeding device, charging system and charging method

A metal wire and material feeding technology, which is applied in the field of metal wire material feeding device, can solve the problems of difficult stable transportation and precise control of metal wire material, and achieve the effect of reducing burning loss and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

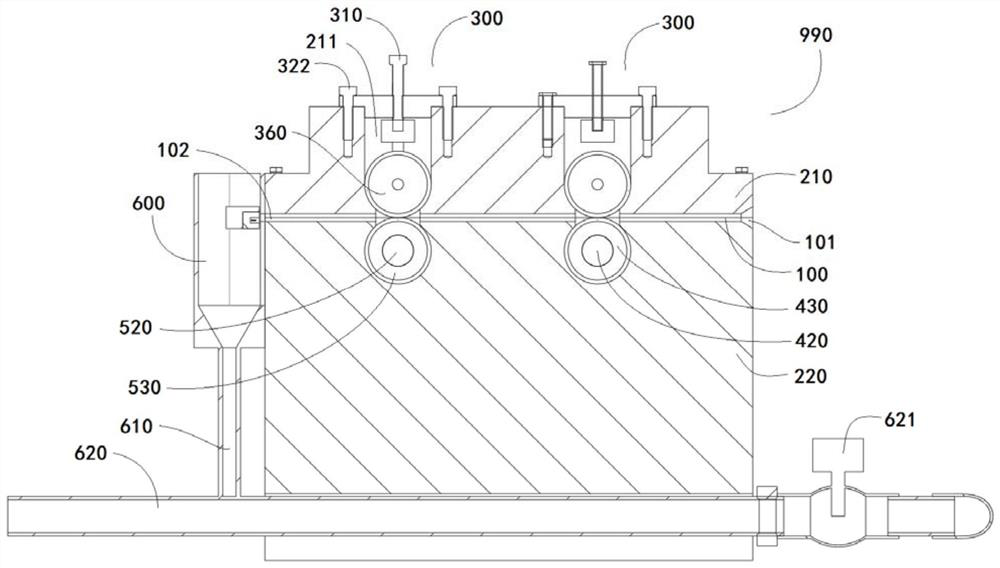

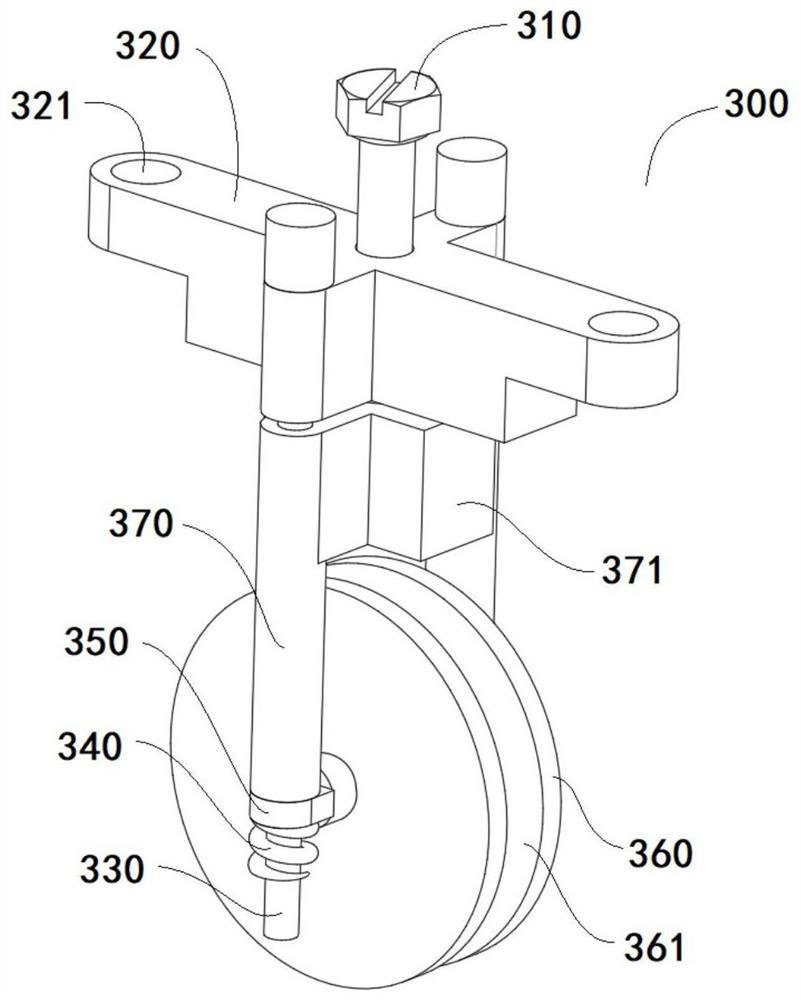

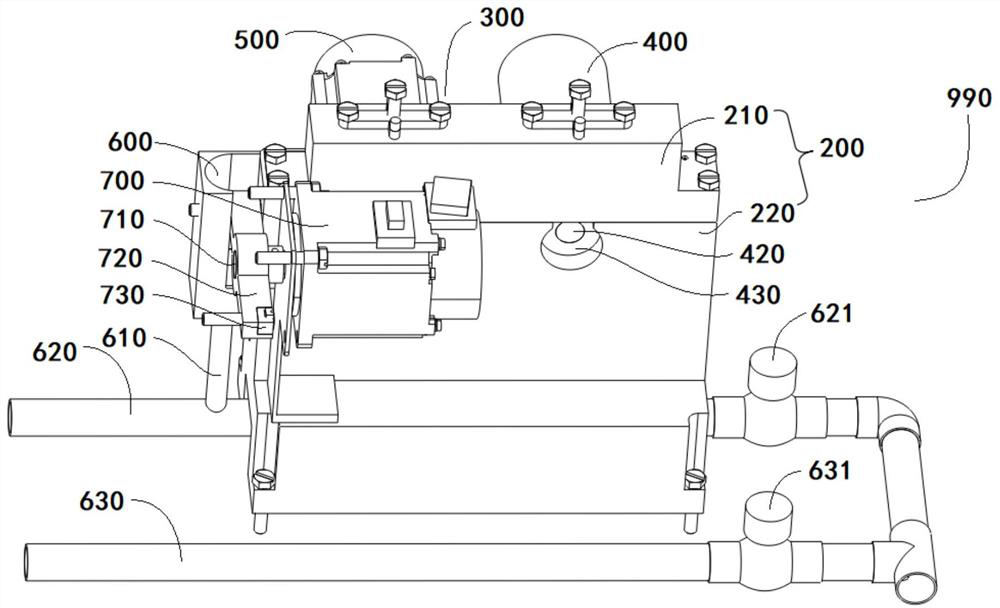

[0055] This embodiment provides a feeding system, specifically an aluminum adding machine for electroslag remelting, such as Figure 6 and Figure 7 As shown, it includes a body 900, a material storage device 800, a feeding device 990, an argon gas station 960, a processor 970 and a controller 910. The bottom of the body 900 is provided with a universal wheel 920 with brakes, which facilitates the fixing and moving of the body 900. with loading. The storage device 800 is arranged at the feeding end of the feeding device 990, and can deliver the metal wire material to the feeding device 990. A guide ring 980 is also provided between the storage device 800 and the feeding device 990. The guide ring 980 can Passing through the metal wire material is used to guide and limit the metal wire material conveyed by the storage device 800 . The storage device 800 , the feeding device 990 and the guide ring 980 are all arranged on the first bottom plate 930 . The processor 970 is electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com