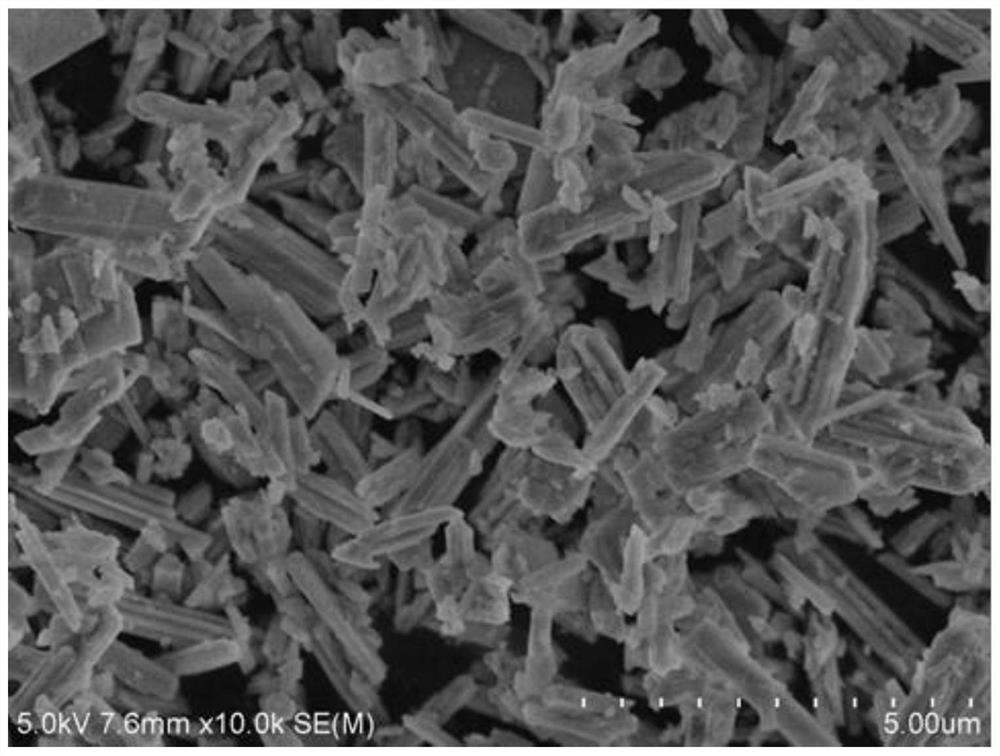

Columnar crystal zirconium oxide powder as well as preparation method and application thereof

A technology of zirconia powder and columnar crystal is applied in the field of inorganic material preparation, which can solve the problems of harsh production conditions, high fusion temperature and high energy consumption, and achieve the effects of increasing productivity and improving visible light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

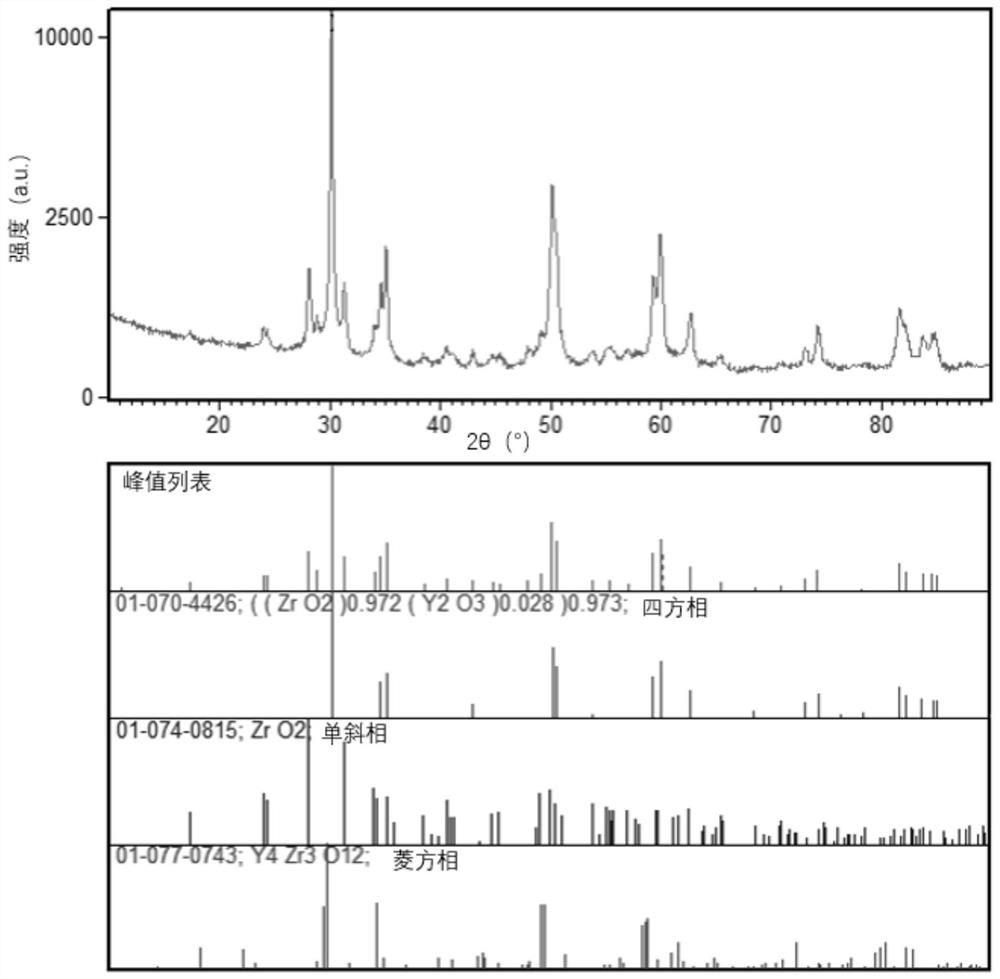

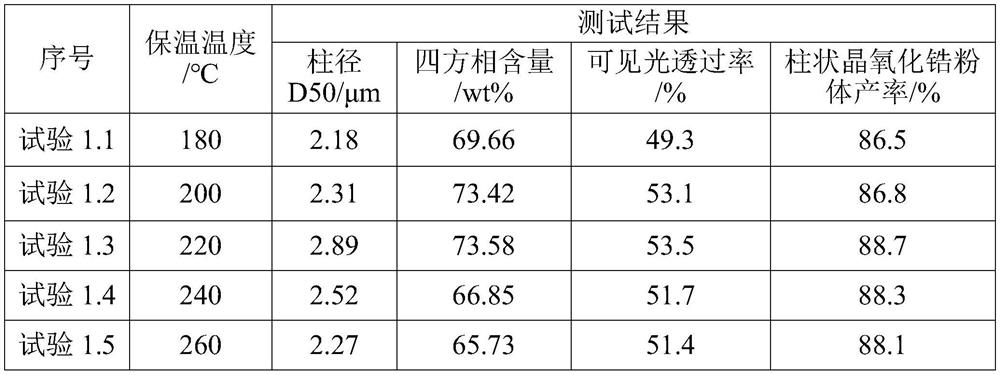

[0063] This embodiment provides a columnar crystal zirconia powder and a preparation method thereof, the composition of the columnar crystal zirconia powder is Al 0.003 Y 0.03 Zr 0.97 o 1.9895 , the preparation method comprises the following steps:

[0064] (1) Liquid preparation: wash a 3000mL beaker with deionized water in advance, accurately weigh out 64.45g zirconium oxychloride octahydrate, 2.30g yttrium nitrate hexahydrate and 0.225g aluminum nitrate nonahydrate in a balance, Pour it into the beaker, and add 1000mL deionized water to dissolve; stir the obtained solution with a digital display magnetic heating stirrer for 3min to form a stable mixed solution; prepare a clean 500mL beaker, and measure 25wt with a graduated cylinder Pour 75mL of ammonia water into it, add 300mL of deionized water, and stir evenly with a glass rod;

[0065] (2) Settling: Start stirring the mixed solution, set the rotating speed to 200r / min, slowly add diluted ammonia water dropwise to it...

Embodiment 2

[0075] This embodiment provides a columnar crystal zirconia powder and a preparation method thereof, the composition of the columnar crystal zirconia powder is Al 0.0025 Y 0.03 Zr 0.97 o 1.98875 , the preparation method comprises the following steps:

[0076] (1) Dosing: Wash five 3000mL beakers with deionized water in advance, and accurately weigh 5 groups of 25.78g zirconium oxychloride octahydrate, 0.92g yttrium nitrate hexahydrate and 0.075g nitric acid nonahydrate in the balance Aluminum, pour into 5 beakers respectively, add 1000mL deionized water for each group to dissolve; stir each group of solutions with a digital display magnetic heating stirrer for 3min to form a stable mixed solution; prepare 5 clean 500mL In a beaker, use a graduated cylinder to measure 30mL of 25wt% ammonia water and pour it into it, add 300mL of deionized water, and stir evenly with a glass rod;

[0077] (2) Settling: Start stirring the mixed solution, set the rotation speed of each group t...

Embodiment 3

[0085] This embodiment provides a columnar crystal zirconia powder and a preparation method thereof, the composition of the columnar crystal zirconia powder is Al 0.003 Y 0.05 Zr 0.95 O1.9795, the preparation method comprises the following steps:

[0086] (1) Dosing: Wash six 3000mL beakers with deionized water in advance, and accurately weigh out six groups of 12.25g zirconium oxychloride octahydrate, 0.767g yttrium nitrate hexahydrate and 0.045g nitric acid nonahydrate in the balance Aluminum, pour into 6 beakers respectively, add 1000mL deionized water for each group to dissolve; stir each group of solutions with a digital display magnetic heating stirrer for 3min to form a stable mixed solution; prepare 6 clean 500mL For each group, use a measuring cylinder to measure 15mL of 25wt% ammonia water and pour it into it, add 300mL of deionized water, and stir evenly with a glass rod;

[0087] (2) Settling: Start stirring the mixed solution, set the rotation speed of each gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com