Fruity beverage packaging film and preparation process thereof

A packaging film and beverage technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor film quality, unstable feeding amount, film breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

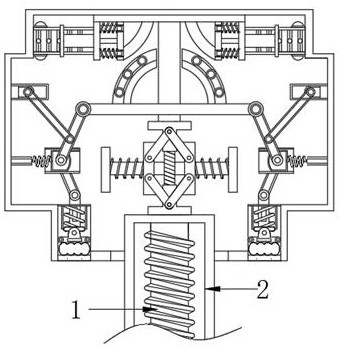

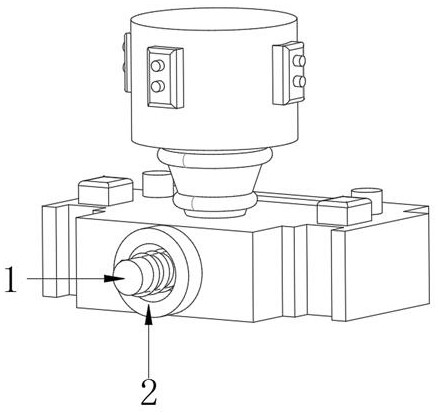

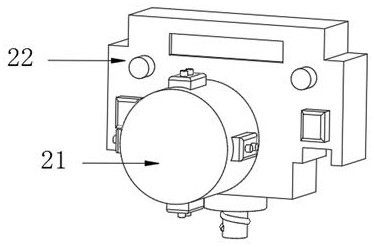

Method used

Image

Examples

Embodiment 1

[0032] Fruity beverage packaging film, comprising the following components in parts by mass: 25 parts of styrene-based thermoplastic elastomer, 50 parts of polyethylene, 50 parts of polypropylene, 10 parts of stearyl acrylate, 50 parts of resin, and film toughening agent 10 servings.

[0033] S1. Put the styrene-based thermoplastic elastomer, polyethylene and polypropylene into the internal mixing device of the film extruder according to the above-mentioned proportioning ratio, raise the temperature to 100 degrees Celsius, and stir the film extruder at a mixing speed of 900r / min;

[0034] S2, then add the above-mentioned parts of stearyl acrylate, resin and film toughening agent into the internal mixing device of the extruder, heat up to 120 degrees Celsius, and then mix, the mixing speed is 1000r / min;

[0035] S3. Heat the inside of the extruder to 200 degrees Celsius to completely melt the raw materials;

[0036] S4. Then the melted raw material is water-cooled and extruded...

Embodiment 2

[0038] Fruity beverage packaging film, comprising the following components in parts by mass: 20 parts of styrene-based thermoplastic elastomer, 40 parts of polyethylene, 40 parts of polypropylene, 8 parts of stearyl acrylate, 40 parts of resin, and film toughening agent 8 servings.

[0039] S1. Put the styrene-based thermoplastic elastomer, polyethylene and polypropylene into the internal mixing device of the film extruder according to the above-mentioned proportioning ratio, raise the temperature to 100 degrees Celsius, and stir the film extruder at a mixing speed of 900r / min;

[0040] S2, then add the above-mentioned parts of stearyl acrylate, resin and film toughening agent into the internal mixing device of the extruder, heat up to 120 degrees Celsius, and then mix, the mixing speed is 1000r / min;

[0041] S3. Heat the inside of the extruder to 200 degrees Celsius to completely melt the raw materials;

[0042] S4. Then the melted raw material is water-cooled and extruded a...

Embodiment 3

[0044] Fruity beverage packaging film, comprising the following components in parts by mass: 15 parts of styrene-based thermoplastic elastomer, 30 parts of polyethylene, 30 parts of polypropylene, 6 parts of stearyl acrylate, 60 parts of resin, and film toughening agent 6 servings.

[0045] S1. Put the styrene-based thermoplastic elastomer, polyethylene and polypropylene into the internal mixing device of the film extruder according to the above proportioning ratio, raise the temperature to 100 degrees Celsius, and stir the film extruder at a mixing speed of 900r / min;

[0046] S2, then add the above-mentioned parts of stearyl acrylate, resin and film toughening agent into the internal mixing device of the extruder, heat up to 120 degrees Celsius, and then mix, the mixing speed is 1000r / min;

[0047] S3. Heat the inside of the extruder to 200 degrees Celsius to completely melt the raw materials;

[0048] S4. Then the melted raw material is water-cooled and extruded at the memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com