Immersive concrete production plant station aggregate system and production plant station

A technology for concrete and production plants, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve problems such as land occupation, and achieve the effect of reducing site demand, shortening construction period, and reducing land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

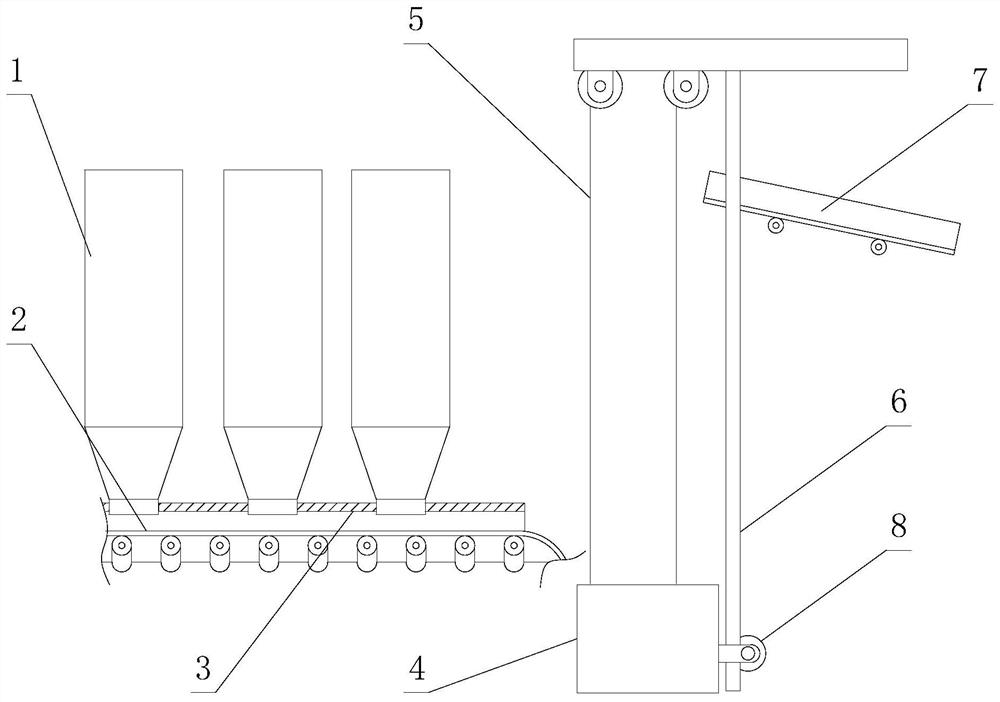

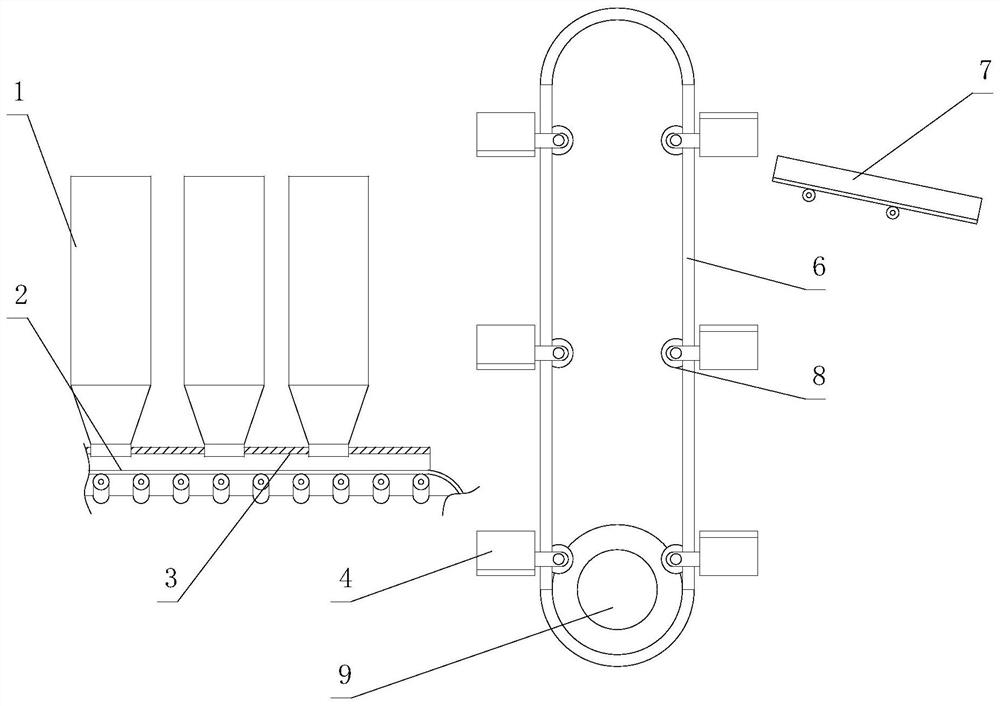

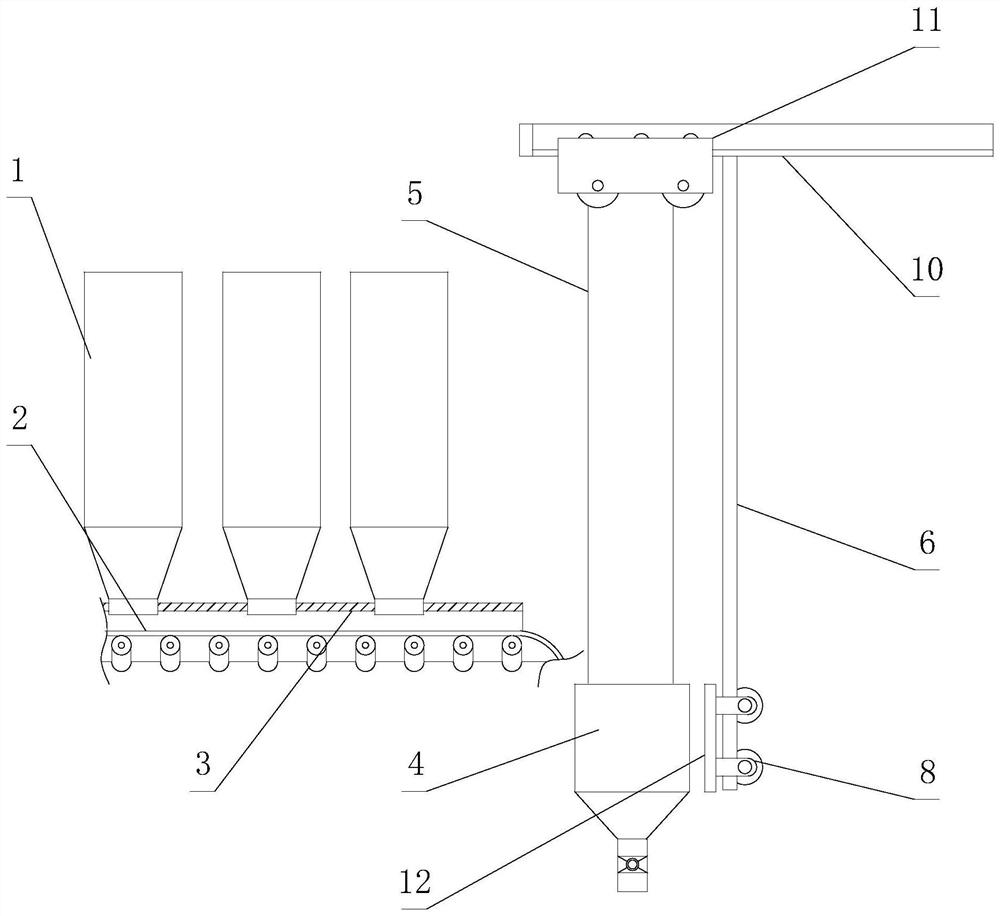

[0065] Such as Figure 1 to Figure 4 As shown, this embodiment relates to the aggregate system of the submerged concrete production plant, including horizontal conveying equipment and vertical conveying equipment. The aggregate inlet end of the vertical conveying equipment is connected to the aggregate outlet end of the horizontal conveying equipment. The vertical conveying equipment includes a receiving hopper 4 for accepting aggregates output by the horizontal conveying equipment, and also includes a rigid frame 6 for constraining the moving track of the receiving hopper 4 in the vertical direction.

[0066] Different from the traditional above-ground concrete production plant in the prior art, the submersible concrete production plant itself is located in a relatively closed space because it is installed underground; the space generally needs to be excavated on site, and the size of the space affects the construction period of the plant and cost; with the change of concrete...

Embodiment 2

[0077] This embodiment is further optimized and refined on the basis of embodiment 1:

[0078] As mentioned above, the receiving hopper 4 is used as one of the intermediate links in the whole process of aggregate transfer, and the problem of aggregate transfer from the receiving hopper 4 to the concrete mixer needs to be considered in the follow-up, as a simple structure, simple operation, vertical conveying equipment The technical solution that occupies a small space and can effectively avoid the loss of lateral restraint of the receiving hopper 4 during the ascent process due to problems such as negligence and accidents is set as follows: the side of the receiving hopper 4 is also equipped with a roller 8 whose axis is in the horizontal direction;

[0079] The wheel surface of the roller 8 is supported on the track surface of the rigid frame 6, and the track surface extends along the vertical direction; the receiving hopper 4 and the roller 8 are located on a pair of opposite...

Embodiment 3

[0085] This embodiment is further optimized and refined on the basis of embodiment 1:

[0086] As a person skilled in the art, the above is only to provide a technical solution that can well adapt to the turning of the receiving hopper 4 to release the aggregate. Considering only the lifting of the receiving hopper 4, the above scheme is actually also applicable to the use of pipelines for releasing aggregates and baffles for releasing aggregates.

[0087] In specific application, considering the requirements for power, volume, installation cost and reliability of the equipment for the way the traction rope 5 lifts the hopper 4, it is preferable to use a hydraulic motor as the power source for the traction rope 5 to be rewound.

[0088] It is equivalent to the above that the material receiving hopper 4 is provided to the concrete mixer by turning the traction rope 5 on the axis of the roller 8, and it is set as follows: it also includes a drag chain system, and the drag chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com