Nitroglycerin sublingual tablet and preparation method thereof

A technology of nitroglycerin and sublingual tablets, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, oil/fat/wax non-active ingredients, etc., and can solve the difficult to meet the requirements of powder direct compression, dependence, fluidity no problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The production of embodiment 1 nitroglycerin sublingual tablet (former prescription)

[0029]Weigh 18.65kg of lactose and put it into a wet granulator. The stirring speed is 120rpm, the cutting speed is 1200rpm, add 3kg 10% nitroglycerin ethanol solution to the liquid addition device, start the liquid addition and finish adding within 90s, and continue to run for 30~60s; the stirring speed is 150rpm, the cutting speed is 1500rpm, and the cutting speed is 30~ 60s, stop and discharge. Spread the granules prepared by the above wet granulation evenly on the baking trays, control the thickness of each tray to no more than 2cm, draw lines horizontally and vertically, turn on the heating, set the heating temperature to 40°C (the control range is 40±5°C), and dry each Turn the material once in about 30 minutes, spread the particles evenly, draw lines horizontally and vertically, and put them back into the oven. Record the temperature about every 30 minutes. After drying for 2 ...

Embodiment 2

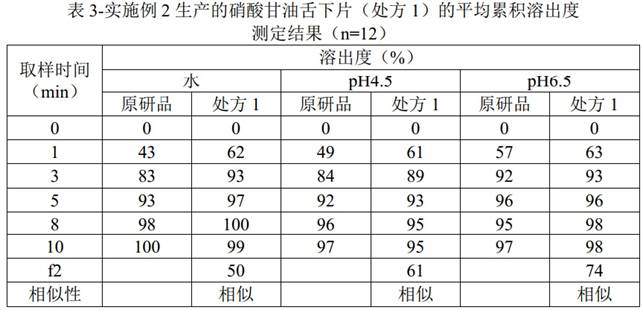

[0031] Production of Example 2 Nitroglycerin Sublingual Tablets (Prescription 1)

[0032] Weigh 3 kg of 10% nitroglycerin ethanol solution, add 0.3 kg of polyoxyethylene 40 hydrogenated castor oil to it under stirring, and stir fully to prepare a clear and transparent mixed solution. Weigh 18.15kg of lactose and put it into a wet granulator. The stirring speed is 120rpm, the cutting speed is 1200rpm, add the above mixed solution into the liquid addition device, start the liquid addition and finish adding within 90s, continue to run for 30-60s; material. Spread the granules prepared by the above wet granulation evenly on the baking trays, control the thickness of each tray to no more than 2cm, draw lines horizontally and vertically, turn on the heating, set the heating temperature to 40°C (the control range is 40±5°C), and dry each Turn the material once in about 30 minutes, spread the particles evenly, draw lines horizontally and vertically, and put them back into the oven. ...

Embodiment 3

[0033] Example 3 Production of Nitroglycerin Sublingual Tablets (Prescription 2)

[0034] Weigh 18 kg of 10% nitroglycerin ethanol solution, add 6 kg of polyoxyethylene 40 hydrogenated castor oil to it under stirring, and stir fully to prepare a clear and transparent mixed solution. Weigh 88.2kg of lactose and put it into a wet granulator. The stirring speed is 120rpm, the cutting speed is 1200rpm, the above mixed solution is added to the dosing device, the dosing is started within 200s, and the operation is continued for 60-90s; material. Spread the granules prepared by the above wet granulation evenly on the baking trays, control the thickness of each tray to no more than 2cm, draw lines horizontally and vertically, turn on the heating, set the heating temperature to 40°C (the control range is 40±5°C), and dry each Turn the material once in about 30 minutes, spread the particles evenly, draw lines horizontally and vertically, and put them back into the oven. Record the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com