Novel ostomy bag capable of preventing infection

A technology for preventing infection and ostomy bag, which is applied in the fields of colostomy, vaccination, ovulation diagnosis, medical science, etc. The effect on the chance of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

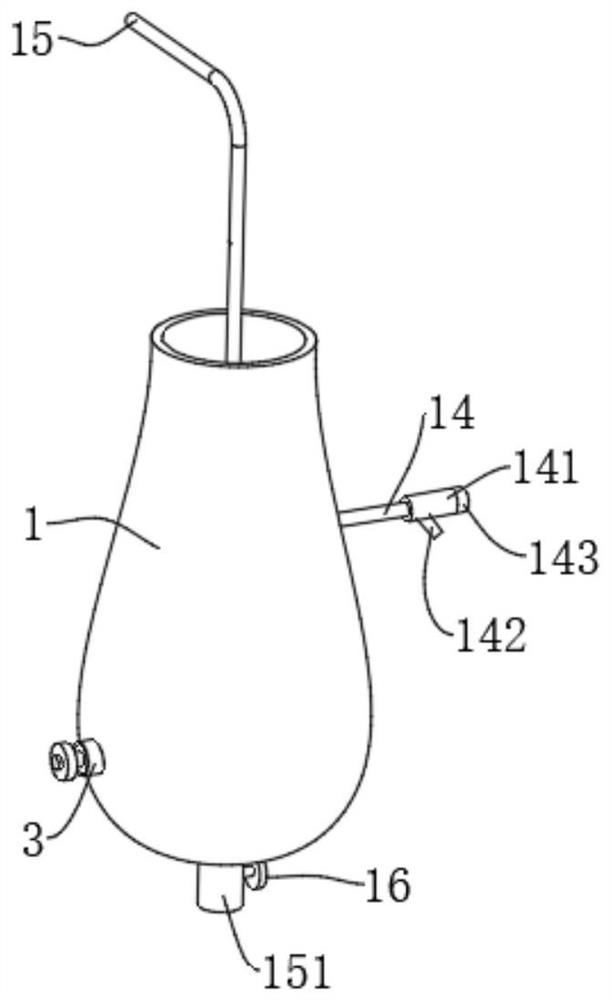

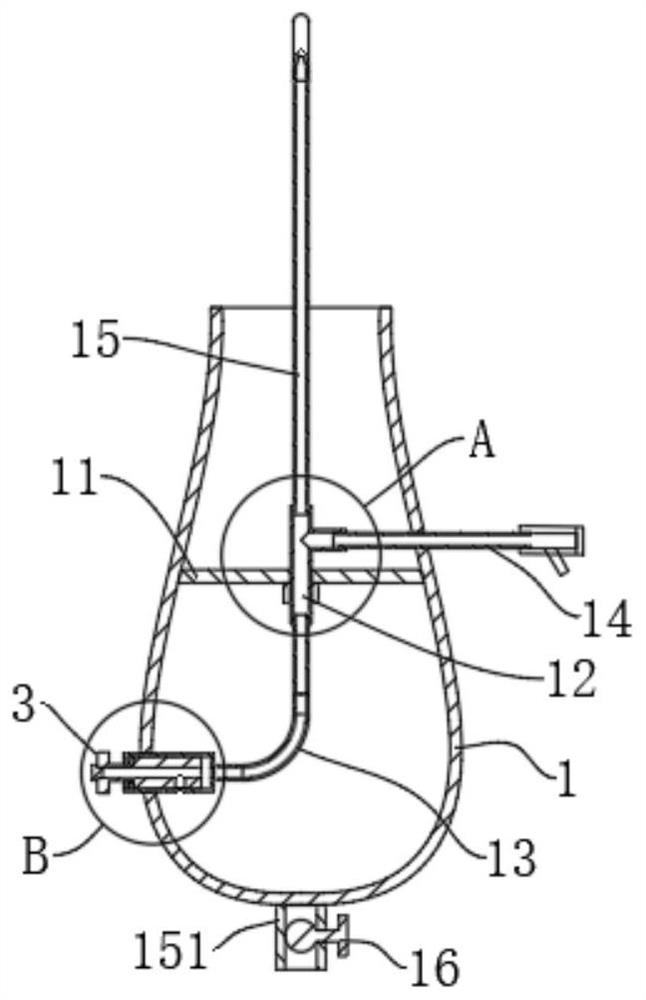

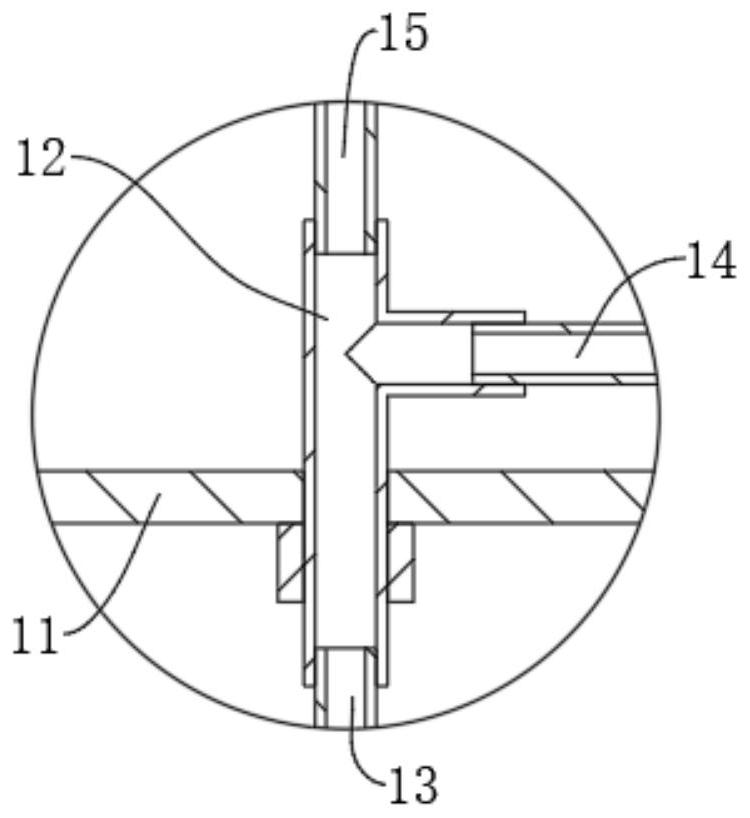

[0043] refer to figure 1 , figure 2 and image 3 , the present embodiment provides a novel ostomy bag for preventing infection, which mainly includes the following parts: a bag body 1 for receiving drainage fluid; a breathable ring 11 fixed in the bag body 1, wherein the breathable ring 11 separates the bag body 1 For the upper and lower parts, the breathable ring 11 can reduce the growth of bacteria and reduce the probability of interference; the three-way joint 12 fixed in the breathable ring 11 has three interfaces, so as to realize multi-pass; the connection is fixed in the three-way The first pipeline 13, the second pipeline 14 and the third pipeline 15 on the joint 12; the weighing early warning component 2 arranged on the bag body 1; the sampling control component 3 arranged at the end of the first pipeline 13; It communicates with the drain pipe 151 fixed at the bottom of the bag body 1 ; and the valve 16 arranged at the drain pipe 151 .

[0044] refer to figure 1...

Embodiment 2

[0056] The difference from Example 1 is that the inner wall of the bag body 1 is coated with an antifouling coating, wherein the preparation process of the antifouling coating is as follows:

[0057] Take the following ingredients by weight: 48 parts of acrylic resin, 65 parts of polyurethane resin, 40 parts of polyvinyl chloride resin, 30 parts of trimethylchlorosilane, 20 parts of n-butyl titanate, 10 parts of propanesultone, polyethylene glycol 10 parts of alcohol, 10 parts of azobisisobutyronitrile, 20 parts of fluorinated polyether siloxane, 14 parts of phenyl o-hydroxybenzoate;

[0058] S1. Preparation of anti-fouling coating pre-preparation solution: add acrylic resin, polyurethane resin, polyvinyl chloride resin, trimethylchlorosilane, n-butyl titanate, and propane sultone to a banbury mixer at 145°C for banburying 1h;

[0059] S2. Preparation of intermediates: Add polyethylene glycol, azobisisobutyronitrile, fluorinated polyether siloxane, and phenyl o-hydroxybenzoat...

Embodiment 3

[0063] The difference from Example 2 is the preparation of antifouling coating, wherein the preparation process of antifouling coating is as follows:

[0064] Take the following ingredients by weight: 41 parts of acrylic resin, 58 parts of polyurethane resin, 40 parts of polyvinyl chloride resin, 30 parts of trimethylchlorosilane, 20 parts of n-butyl titanate, 15 parts of propanesultone, polyethylene glycol 17 parts of alcohol, 14 parts of azobisisobutyronitrile, 20 parts of fluorinated polyether siloxane, 14 parts of phenyl o-hydroxybenzoate;

[0065] S1. Preparation of anti-fouling coating pre-preparation solution: add acrylic resin, polyurethane resin, polyvinyl chloride resin, trimethylchlorosilane, n-butyl titanate, and propane sultone to a 148°C internal mixer for internal mixing 1h;

[0066] S2. Preparation of intermediates: Add polyethylene glycol, azobisisobutyronitrile, fluorinated polyether siloxane, and phenyl o-hydroxybenzoate to the antifouling coating pre-prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com