Pipe joint and connecting method for inducing cold flow through axial resultant force of asymmetric annular grooves

A connection method and asymmetric technology, applied in the field of pipe joints, can solve the problem of increasing fatigue fracture on the inner surface of the conduit, and achieve the effects of increasing the necessary dislocation density, reducing the processing stress, and reducing the processing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

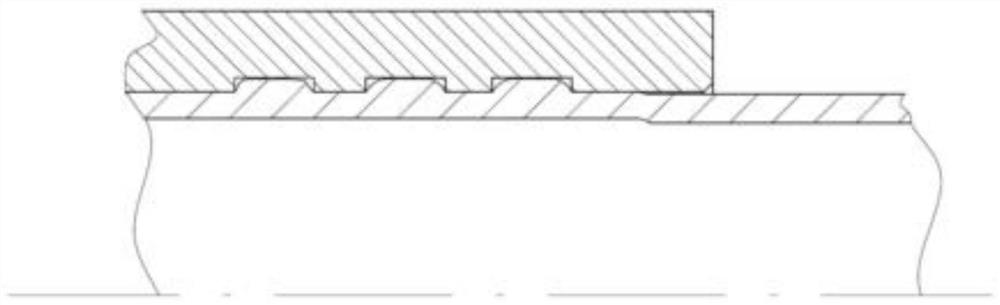

[0056] Such as Figure 2 to Figure 9 As shown, the present invention provides a pipe joint for inducing cold flow by an asymmetrical ring groove in the axial direction. Several annular grooves are arranged in the conduit; the annular grooves include an asymmetric annular groove, and the asymmetric annular groove includes a groove bottom 3, one side of the groove bottom 3 is connected with a first groove wall 2 The first groove top 1, the other side of the groove bottom 3 is connected with the second groove roof 5 through the second groove wall 4, the first groove wall 2 and the second groove wall 4 are connected with the inner hole The included angles between the axes are different, resulting in an asymmetrical arrangement. Wherein, the first groove wall 2 is arranged obliquely, which means that the angle between the groove wall and the axial direction of the inner hole is not equal to 90°.

[0057] In this embodiment, all or part of the traditional symmetrical ring grooves ...

Embodiment 2

[0109] This embodiment is an improvement made on the basis of Embodiment 1, and its improvements are as follows:

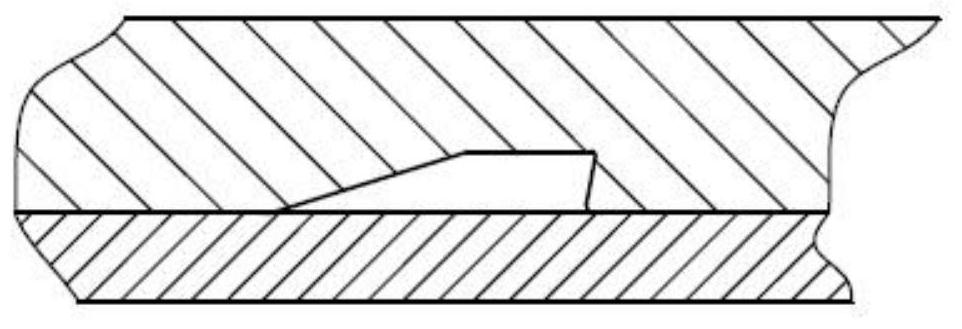

[0110] There is a transition of a circular arc R between the first groove wall 2 and the first groove top 1, such as Figure 10 As shown, a circular arc rotating transition surface is formed between the curved surface of the groove wall and the curved surface of the groove top;

[0111] Similarly, the arc R transition can exist at any one or several of the four junctions among the first groove wall 2 , the first groove top 1 , the groove bottom 3 , the second groove wall 4 , and the second groove top 5 . As we all know, the transition of the arc can reduce the local stress concentration and facilitate the processing.

[0112] In order to optimize the cold flow of materials, the characteristic dimensions A, B, H, a, b, R of the asymmetric ring groove, such as Figure 11 shown.

Embodiment 3

[0114] This embodiment is an improvement made on the basis of Embodiment 1, and its improvements are as follows:

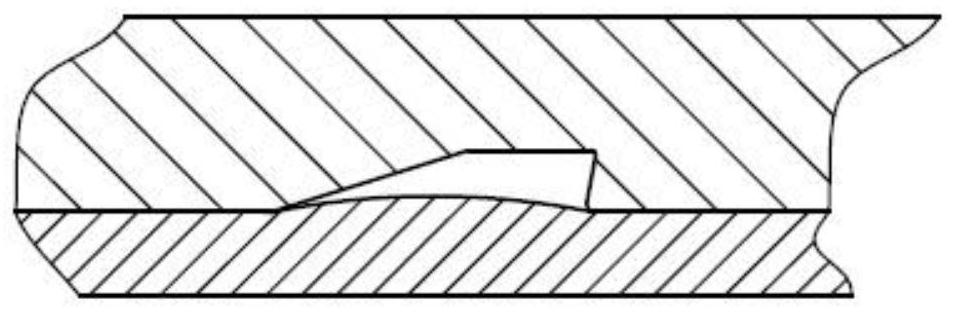

[0115] Such as Figure 12 As shown, the second groove wall 4 and the second groove top 5 are improved into right-angled sides (b=90°) for easy processing, and three asymmetric annular grooves in the same direction are arranged in the pipe joint body structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com