Novel section figured steel and production method thereof

A production method and technology of special-shaped steel, which are applied in the directions of slender elements, load hanging elements, building elements, etc., can solve the problems of unsatisfactory requirements, small section modulus of I-beams, weak bearing capacity, etc., and improve production. Efficiency, improving metal utilization rate, and the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The specification of the blank of this embodiment is the continuous casting billet (material Q345) of 160 * 160mm section, comprises the following steps:

[0053] 1) Heating the billet to 1100-1150°C;

[0054] 2), utilize the billet opening machine that is provided with 6 passes to carry out rough rolling to the billet heated in step 1), obtain the rolled piece after 8 pass rollings;

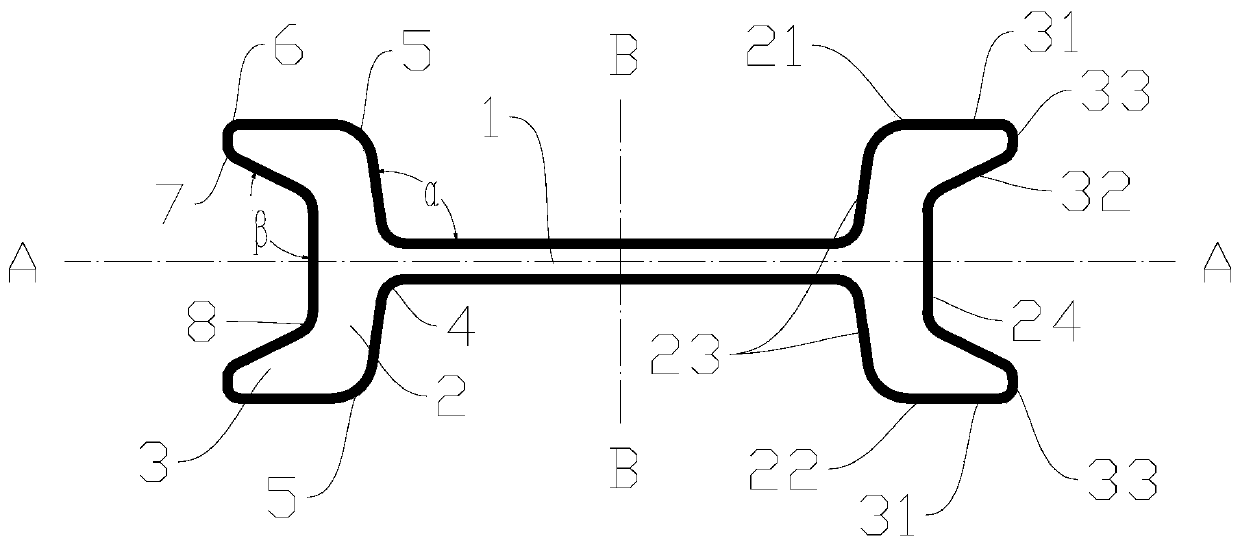

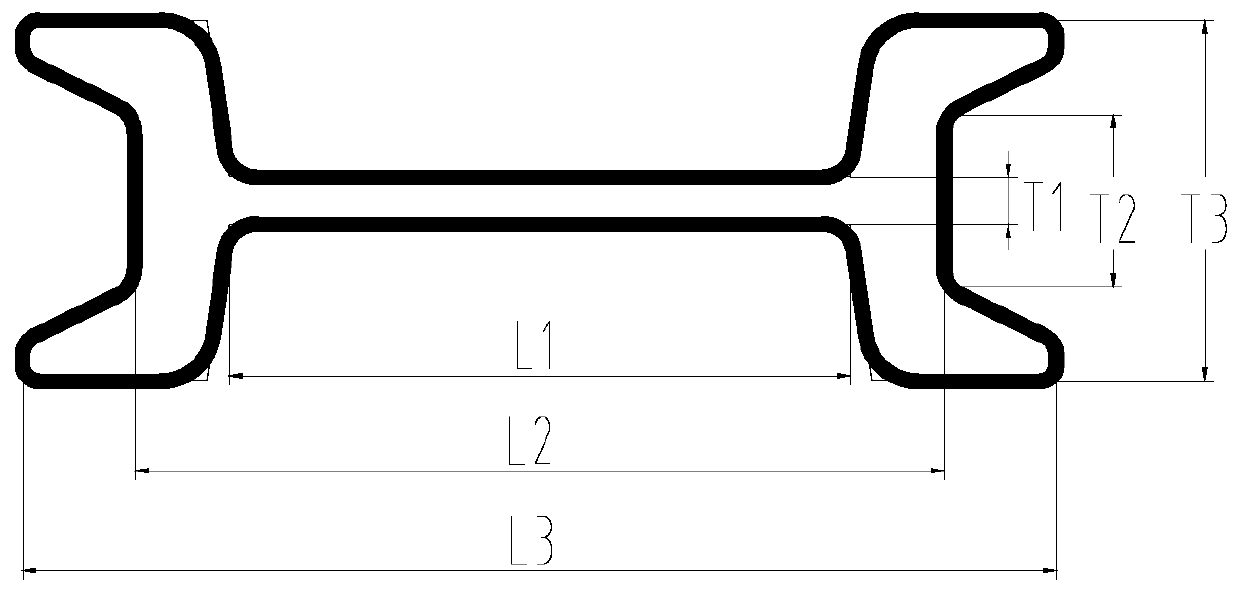

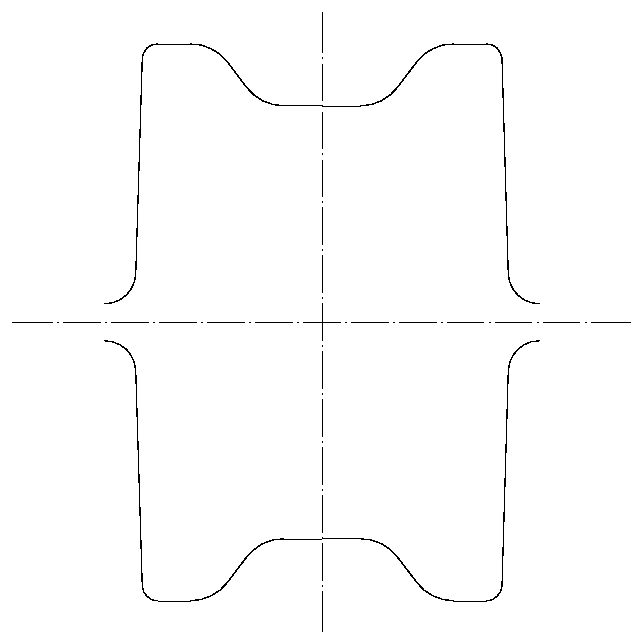

[0055] The billet opening machine is arranged with six pass types of K1, K2, K3, K4, K5, and K6 in sequence. image 3 As shown, K1, K3, and K5 are all longitudinal openings and split holes, such as Figure 4 As shown, K2, K4, and K6 are all transversely opened cutting holes. The longitudinal opening cutting hole is used for forming the flange 2 and the corner 3; the transverse opening cutting hole is used for the widening and thinning of the web 1, and the thickness of the web 1 of the rolled piece obtained after rough rolling is 16mm .

[0056] 3), using 3 universal rolling mills and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com