A green printing process for packaging boxes based on water-based ink

A technology of water-based ink and packaging box, which is applied in packaging, transportation and packaging, and the manufacture of rigid/semi-rigid containers. It can solve the problems of poor water resistance of printing ink, inconvenient practical application, and poor printing effect, and achieve excellent water resistance. , high practicability, excellent printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

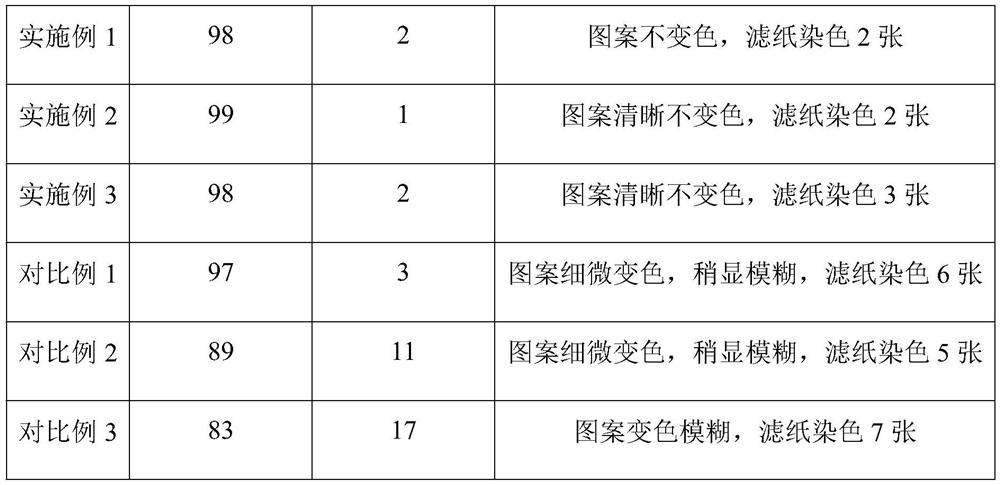

Embodiment 1

[0034] A water-based ink-based green printing process for packaging boxes, comprising the following steps:

[0035] (1) Mix dopamine hydrochloride, polyethyleneimine and Tris-HCl uniformly, pH is 8.5, soak and immerse the packaging box substrate for 2 hours, take it out, wash and dry to obtain a pretreated substrate; dopamine hydrochloride The concentration is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0036] (2) Take 0.2 g of silica and 90 mL of toluene, and after mixing, ultrasonically disperse for 20 min, add 0.2 g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 10 mL of toluene mixed solution under an argon atmosphere, 70 The reaction was stirred at °C for 5 h, collected by centrifugation, washed and dried to obtain filler silica;

[0037] Take 100 g of tung oil, 14.3 g of ethylene glycol and 0.6 g of zinc acetate, raise the temperature to 120 ° C under nitrogen, react for 9 h, collect the product, wash with deionized wat...

Embodiment 2

[0045] A water-based ink-based green printing process for packaging boxes, comprising the following steps:

[0046] (1) Mix dopamine hydrochloride, polyethyleneimine and Tris-HCl uniformly, pH is 8.5, soak and immerse the packaging box substrate for 2.5 hours, wash and dry after taking it out, to obtain a pretreated substrate; dopamine hydrochloric acid The concentration of salt is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0047] (2) Take 0.2 g of silica and 90 mL of toluene, and after mixing, ultrasonically disperse for 25 min, add 0.2 g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 10 mL of toluene mixed solution under an argon atmosphere, 72 The reaction was stirred at ℃ for 4.5 h, collected by centrifugation, washed and dried to obtain filler silica;

[0048] Take 100g of tung oil, 14.3g of ethylene glycol and 0.6g of zinc acetate, heat up to 125°C under nitrogen, react for 8.5h, collect the product, wash with deionize...

Embodiment 3

[0056] A water-based ink-based green printing process for packaging boxes, comprising the following steps:

[0057] (1) Take dopamine hydrochloride, polyethyleneimine and Tris-HCl and mix them evenly, the pH is 8.5, soak and immerse the packaging box substrate for 3 hours, take it out, wash and dry to obtain a pretreated substrate; dopamine hydrochloride The concentration is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0058] (2) Take 0.2 g of silica and 90 mL of toluene, and after mixing, ultrasonically disperse for 30 min, add 0.2 g of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and 10 mL of toluene mixed solution under an argon atmosphere, 75 The reaction was stirred at ℃ for 4 h, collected by centrifugation, washed and dried to obtain filler silica;

[0059] Take 100 g of tung oil, 14.3 g of ethylene glycol and 0.6 g of zinc acetate, raise the temperature to 130 ° C under nitrogen, react for 9 h, collect the product, wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com