Heat-resistant and anti-aging high polymer material and preparation method thereof

A polymer material and anti-aging technology, which is applied in the field of automotive polymer materials, can solve the problems of reducing the density of nylon materials, and achieve the effects of easy operation, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

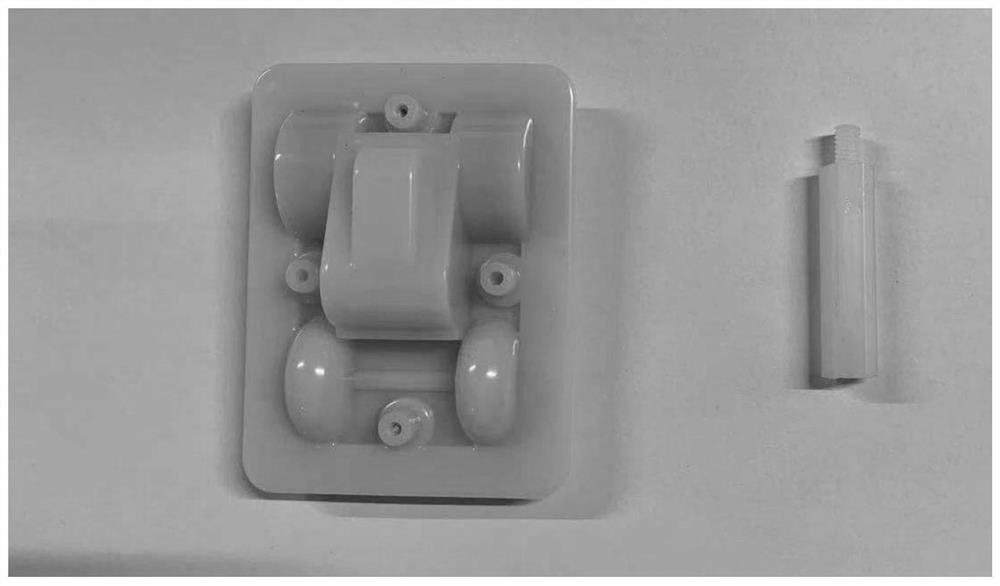

Image

Examples

Embodiment 1

[0026] The raw materials were weighed according to the following mass: 100g of polyamide resin, 4g of kaolin, 2g of carbon fiber, 0.5g of composite nucleating flow agent, 5g of peroxybenzoic acid, 3g of Fischer-Tropsch wax, and 0.2g of antioxidant. The composite nucleating flow agent prepared includes linolenic acid, sodium benzoate, sodium carboxymethylcellulose, and talcum powder, the mass ratio of which is 0.8:1:1:0.1. The mineral filler is powdered kaolin with particle size ≤ 5 microns, purity ≥ 95%, and carbon fiber length ≤ 0.5 cm.

[0027] First prepare the composite nucleating flow agent:

[0028] (1) Mix talcum powder and water according to the mass ratio of 1:50, stir well and make suspension system;

[0029] (2) Add sodium benzoate and sodium carboxymethylcellulose into the suspension system at a mass ratio of 1:1, stir until dissolved, then heat to 65°C, then add linoleic acid, and stir at 350rpm for 3.5h, Then ultrasonic dispersion with 25KHz ultrasonic wave was...

Embodiment 2

[0035] The raw materials were weighed according to the following mass: 150g of polyamide resin, 6g of kaolin, 4g of glass fiber, 1g of composite nucleating flow agent, 6g of peroxybenzoic acid, 4g of Fischer-Tropsch wax, and 0.1g of antioxidant. Wherein the composite nucleating flow agent prepared is prepared in Example 1. The mineral filler is powdered calcium carbonate with particle size ≤ 5 microns, purity ≥ 95%, and glass fiber length ≤ 0.5 cm.

[0036] Preparation of composite polymer materials:

[0037] (1) PA66 polyamide resin, calcium carbonate, composite nucleating flow agent, peroxybenzoic acid, Fischer-Tropsch wax, and antioxidant are added in a high-speed mixer and mixed uniformly to obtain a mixture;

[0038] (2) Place the obtained mixture in a twin-screw machine with a rotation speed of 250rpm. After heating the heating zone to 220-230°C, add glass fibers, heat again to 260-275°C, and then cool down to 220-250°C for extrusion particles to obtain polymer materia...

Embodiment 3

[0040] The raw materials were weighed according to the following mass: 200g polyamide resin, 10g part kaolin, 6g part glass fiber, 2g composite nucleating flow agent, 8g peroxybenzoic acid, 5g Fischer-Tropsch wax, 1g antioxidant. Wherein the composite nucleating flow agent prepared is prepared in Example 1. The mineral filler is powdered wollastonite with particle size ≤ 5 microns, purity ≥ 95%, and glass fiber length ≤ 0.5 cm.

[0041] Preparation of composite polymer materials:

[0042] (1) Add PA66 polyamide resin, wollastonite, composite nucleating flow agent, peroxybenzoic acid, Fischer-Tropsch wax, and antioxidant into a high-speed mixer and mix uniformly to obtain a mixture;

[0043] (2) Place the obtained mixture in a twin-screw machine with a rotation speed of 250rpm. After heating the heating zone to 220-230°C, add glass fibers, heat again to 260-275°C, and then cool down to 220-250°C for extrusion particles to obtain polymer materials.

[0044] The polymer materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com