Production line of air conditioner piping assembly and brazing process

A technology for air conditioners and production lines, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of low manual welding efficiency and unguaranteed welding quality, and achieve excellent use effect, high degree of automation, and fast brazing The effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

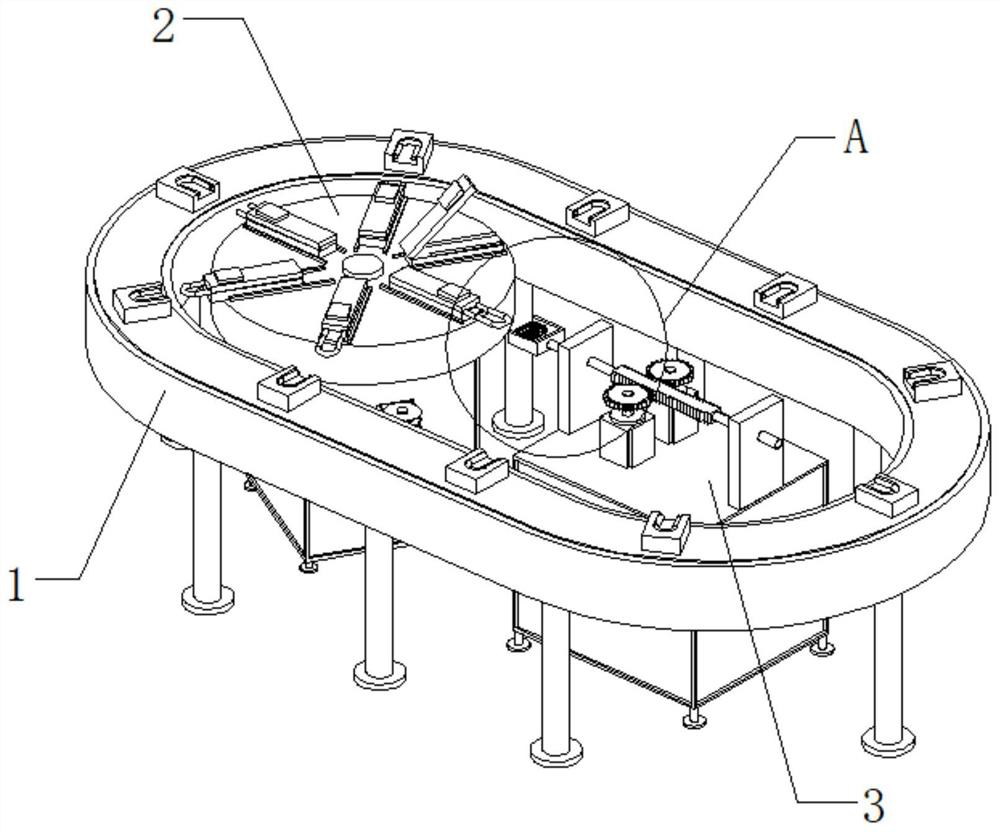

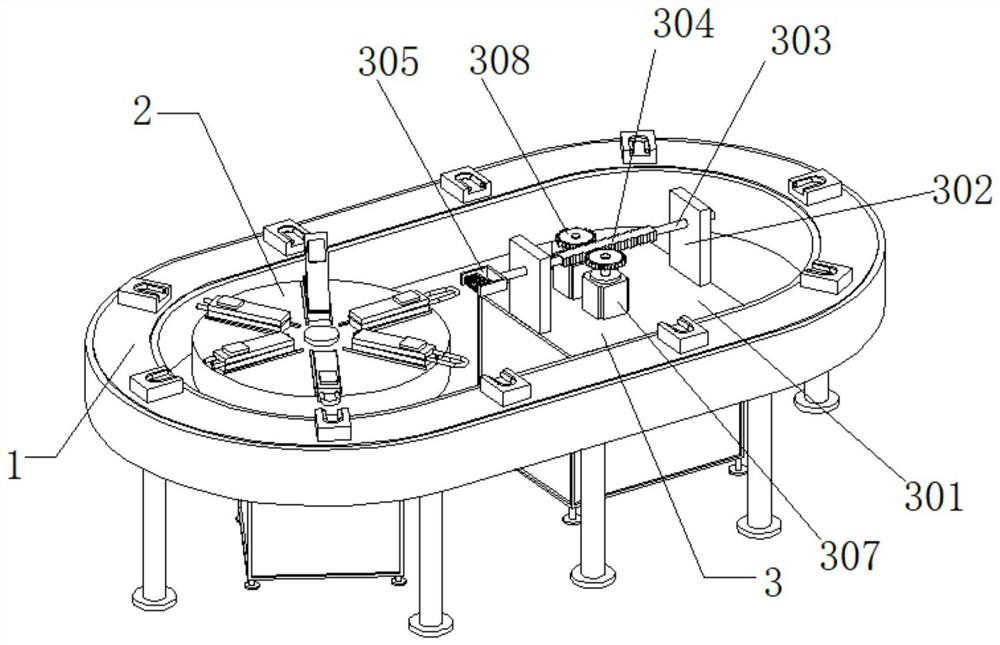

[0045] This embodiment 1 discloses a production line for air conditioner piping components, refer to the attached figure 1 , attached figure 2 And attached image 3 , The main equipment of the device includes a U-shaped pipe head feeder 1, a side pipe feeder 2 and a welding device 3.

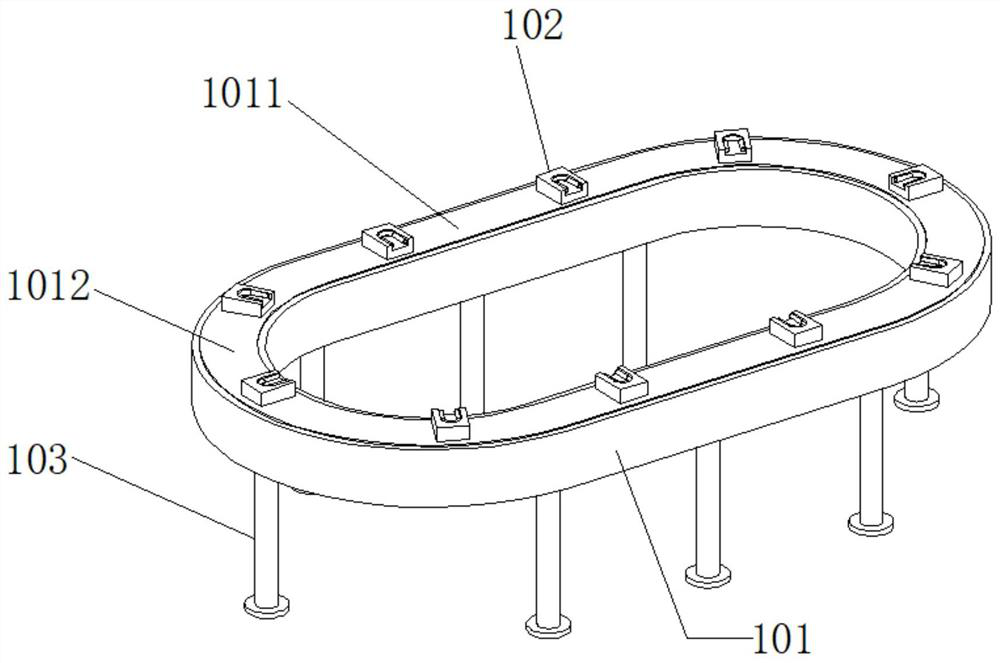

[0046] Reference attached image 3 , wherein the U-shaped pipe head feeder 1 includes a closed-loop conveyor 101. When specifically configured, the closed-loop conveyor 101 is composed of two straight line segments 1011 before and after, and two semicircular line segments 1012 on the left and right. delivery path. On the upper surface of the closed-loop conveyor 101, a plurality of fixed blocks 102 are fixedly connected at intervals, and the upper surface of each fixed block 102 is provided with a U-shaped groove for placing a U-shaped pipe head. 1 The manipulator on the side (not shown in the figure) can put the U-shaped pipe head in the air conditioner piping assembly into the U-shaped gr...

Embodiment 2

[0053] This embodiment 2 discloses a production line of an air conditioner piping assembly improved on the basis of embodiment 1. Its similarities with embodiment 1 will not be described again, and the difference lies in:

[0054] Reference attached figure 1 , attached figure 2 And attached Figure 10 , the welding device 3 in the present embodiment 2 includes a welding machine base 301, and a plurality of shock-absorbing feet 400 are also connected to the lower surface of the welding machine base 301, and convex plates 302 are connected to the left and right ends of the upper surface of the welding machine base 301 , the two convex plates 302 are provided with relative perforations, and horizontal slide bars 303 are arranged in the two perforations, and a double-sided rack 304 is connected between the two horizontal slide bars 303. The end of the horizontal slide bar 303 is connected with a U-shaped connecting block 305, wherein the U-shaped connecting block 305 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com