Hierarchical porous carbon material, and preparation method and application thereof

A carbon material, multi-level porous technology, applied in the field of biomass carbon adsorbent preparation, can solve the problems of limited volatile organic compound adsorption performance, inability to large-scale production and application, complex porous carbon material methods, etc., and achieves low cost and high cost. Specific surface area, rich source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

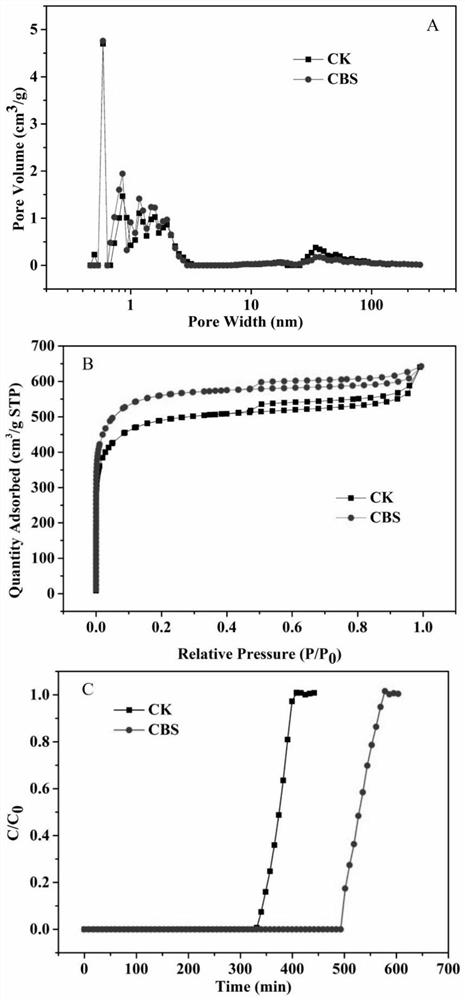

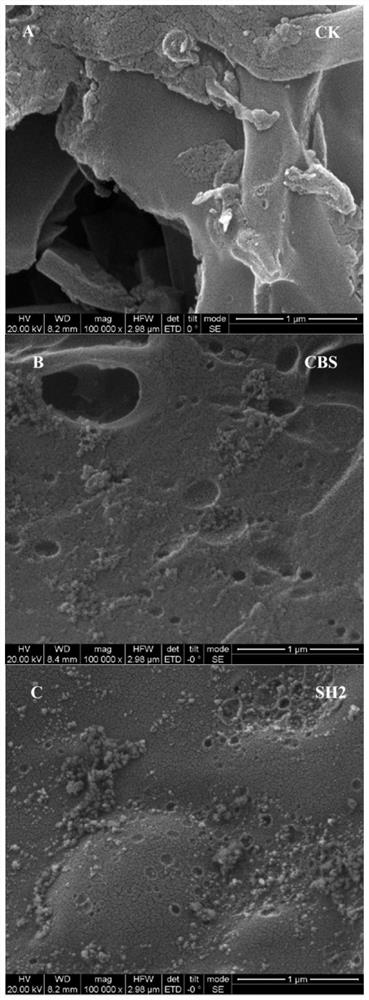

Embodiment 1

[0046] A method for preparing a porous carbon material by pretreating brewer's grains with spore-forming Aspergillus niger (Aspergillus niger CBS513.88), comprising the steps of:

[0047] (1) The brewer's grains with high water content obtained from the brewery were filtered through four layers of gauze to remove water, and washed three times with ultrapure water. Then the brewer's grains washed with gauze and dewatered are placed in a normal room, air-dried naturally, and set aside;

[0048] (2) Spread and inoculate the spore-forming Aspergillus niger (Aspergillus niger CBS513.88) glycerin preserved strain on potato dextrose agar medium (PDA), PDA medium: potato powder 200g / L, glucose 20g / L, agar 20g / L L, pH 5.6. Collect spores after culturing at 30°C for 7 days, and use the collected spores as the inoculum for later use;

[0049] (3) Inoculate the spore liquid prepared in step (2) into 500 mL of potato glucose fermentation medium, and add 15 g of naturally air-dried brewer'...

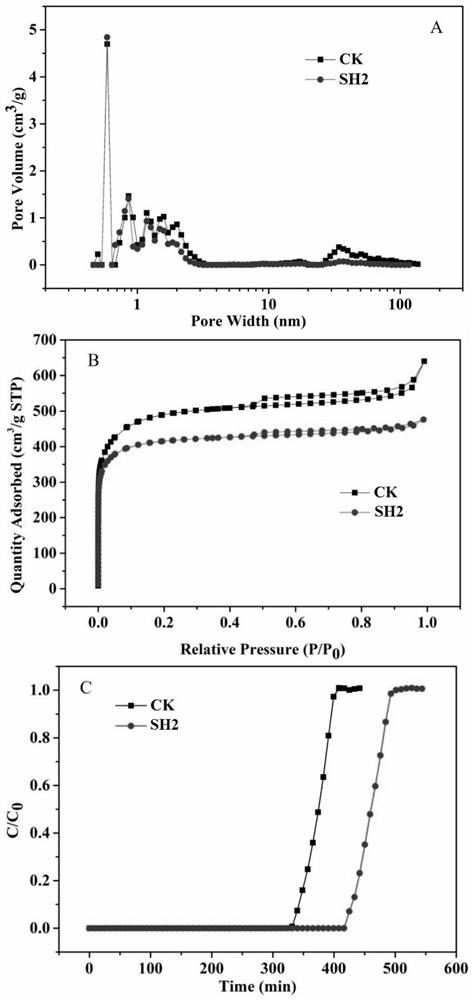

Embodiment 2

[0055] A method for preparing a porous carbon material by pretreating brewer's grains without spore-forming Aspergillus niger (Aspergillus niger SH2), comprising the steps of:

[0056] (1) The brewer's grains with high water content obtained from the brewery were filtered through four layers of gauze to remove water, and washed three times with ultrapure water. Then the brewer's grains washed with gauze and dewatered are placed in a normal room, air-dried naturally, and set aside;

[0057] (2) Inoculate non-spore-producing Aspergillus niger (Aspergillus niger SH2) glycerol preserved strains in liquid CD medium, CD medium: glucose 20g / L, potassium chloride 2g / L, magnesium sulfate heptahydrate 0.5g / L, phosphoric acid Potassium dihydrogen 1g / L, ferrous sulfate heptahydrate 0.01g / L, sodium nitrate 3g / L, agar 0.05%. Cultivate at 30°C for 5 days and set aside;

[0058] (3) Inoculate the mycelia liquid prepared in step (2) into 500 mL of potato glucose fermentation medium, and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com