Method for detecting the dynamic flexural fatigue performance of tubular conveyor belt

A tubular conveyor belt and fatigue performance technology, which is applied in the direction of using repetitive force/pulse force to test the strength of materials, can solve the problem of lack of dynamic flexural fatigue performance of tubular conveyor belts, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The dynamic flex fatigue performance test of 2 tubular conveyor belts with a skeleton material of canvas and a pipe diameter of 500mm.

[0026] The detection method of the dynamic flex fatigue performance of the tubular conveyor belt includes the following steps:

[0027] (1) Stand still: take the tubular conveyor belt, and prepare a tubular conveyor belt sample of a certain length, and the sample length is 500 mm. Place it in an environment with a temperature of 22-24°C for more than 4 hours before testing;

[0028] (2) Adjustment: Adjust the pipe diameter of the tubular conveyor belt to 500mm;

[0029] (3) Test: The prepared sample is installed on the tubular conveyor belt dynamic flex fatigue testing machine, so that the center line of the overlapping part of the tubular conveyor belt is aligned with the center line of the pressure roller on the tubular conveyor belt dynamic flex fatigue testing machine; adjust the sample to In a balanced position, set the displace...

Embodiment 2

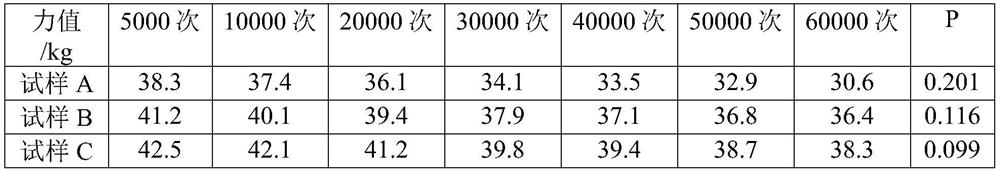

[0034] Three skeleton materials are steel wire ropes, and the dynamic flexion fatigue performance test of tubular conveyor belts with a pipe diameter of 450mm. The core rubber thicknesses of samples A, B, and C are 1mm, 4mm, and 6mm respectively, and the rest of the materials and specifications are the same.

[0035] The detection method of the dynamic flex fatigue performance of the tubular conveyor belt includes the following steps:

[0036] (1) Stand still: take the tubular conveyor belt, and prepare a tubular conveyor belt sample of a certain length, and the sample length is 450 mm. Place it in an environment with a temperature of 22-24°C for 12 hours before testing;

[0037] (2) Adjustment: Adjust the pipe diameter of the tubular conveyor belt to 450mm;

[0038] (3) Test: The prepared sample is installed on the tubular conveyor belt dynamic flex fatigue testing machine, so that the center line of the overlapping part of the tubular conveyor belt is aligned with the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com