A smelting method for producing φ12-25mmhrb500e straight bars by microalloying

A smelting method and microalloying technology, applied in the field of metallurgy, can solve problems such as brittle fracture of steel bars and increased quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

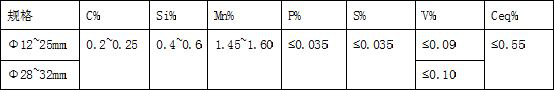

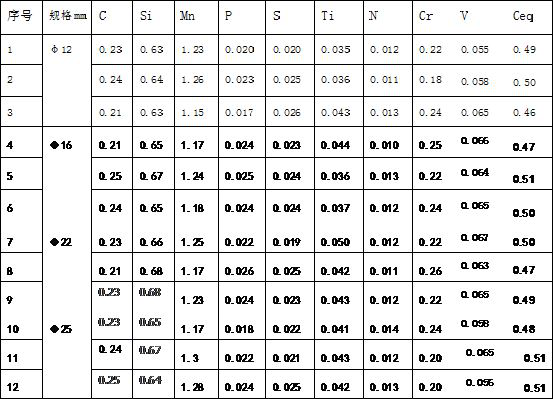

[0027]A smelting method for producing Φ12-25mmHRB500E straight steel bars by microalloying. %, P: ≤0.04%, N: 0.01~0.015%, Ti: 0.03~0.05%, V: 0.05~0.07%, Cr: 0.1~0.3%, the sum of the mass percentages of Cr+Mn ≤1.55%, Ceq ≤0.54%; smelting method: adding pre-deoxidized composite slag lotion in converter tapping, the mass percentage composition of the slag lotion is: fluorite 5-10%, calcium carbide 65-75%, limestone 15-25%; Ti, V-composite micro-alloying smelting process technology and process steps, control the timing of adding Ti iron and the application of new materials to increase N in molten steel, that is, the application of high-nitrogen composite strengtheners, control high Si content, add Cr, reduce Mn, and realize Ti, V composite micro Alloy production of small size Φ12-25mmHRB500E straight steel bars: the carbon content at the end of the converter is less than or equal to 0.06%, and the amount of pre-deoxidized composite slag lotion is 2.0 kg / t; The dosage of agent add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com