Converter with replaceable furnace bottom and construction method for primary masonry

A construction method and converter technology, applied in the manufacture of converters, etc., can solve the problem of easy adhesion and combination of joint materials and furnace body refractory materials, joint material and furnace body refractory materials are not easy to separate, and affect the construction efficiency of furnace bottom heat replacement and other problems, to achieve the effect of easy disassembly and cleaning, good high temperature strength and performance, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

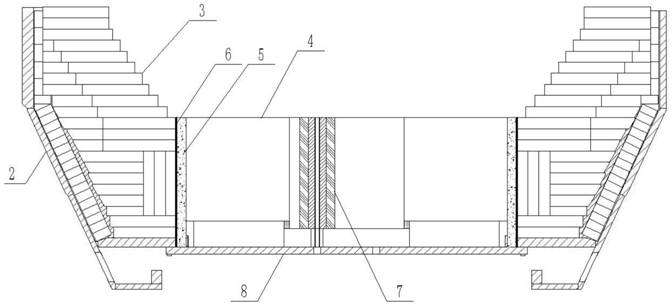

[0032] A converter with a replaceable bottom, such as figure 1 As shown, it includes a detachable converter bottom shell 8 and a converter body shell 2, the furnace body refractory material 3 is built on the inner side of the converter body shell 2, and the furnace bottom refractory material 4 is built on the converter bottom shell 8, The converter bottom shell 8 is detachably fixed on the converter body shell 2 by bolts, an annular gap is formed between the furnace body refractory material 3 and the furnace bottom refractory material 4, and the furnace body refractory material 3 is in the annular gap An isolation layer 6 is pasted on the vertical surface on one side.

[0033] As a preferred embodiment, the isolation layer 6 is aluminum foil paper, the thickness of the aluminum foil paper is 0.025mm, and the width of the annular gap is between 30-100mm. Sewing material5.

[0034] As a preferred embodiment, a gas supply and powder injection system 7 runs through between the c...

Embodiment 2

[0037] A converter with a replaceable bottom, such as figure 1 As shown, it includes a detachable converter bottom shell 8 and a converter body shell 2, the furnace body refractory material 3 is built on the inner side of the converter body shell 2, and the furnace bottom refractory material 4 is built on the converter bottom shell 8, The converter bottom shell 8 is detachably fixed on the converter body shell 2 by bolts, an annular gap is formed between the furnace body refractory material 3 and the furnace bottom refractory material 4, and the furnace body refractory material 3 is in the annular gap An isolation layer 6 is pasted on the vertical surface of one side

[0038] As a preferred embodiment, the isolation layer 6 can also be made of glass fiber aluminum foil cloth, or pure cotton cloth, or carbon fiber cloth material, which can also isolate the adhesion between the furnace body refractory material and the ramming material. The converter is easy to disassemble and c...

Embodiment 3

[0040] The solid materials used in the ramming joint material in this example are 70wt% fused magnesia particles, 16wt% fused magnesia fine powder, 12wt% high iron and high calcium sand fine powder, 5wt% medium temperature asphalt fine powder, 1.2wt% Metal aluminum powder, 1.5wt% silicon carbide fine powder, 1.2wt% solid resin, and 3.6wt% washing oil as liquid material.

[0041] As a preferred embodiment, the content of MgO in the fused magnesia particles is 97wt%, and the particle size is 3mm; the content of MgO in the fine powder of fused magnesia is 97wt%, and the particle size is 0.08mm; The content of MgO in fine powder is 85wt%, Fe 2 o 3 The content of CaO is 6wt%, the content of CaO is 10wt%, and its particle size is 0.08mm; the softening point of medium-temperature asphalt fine powder is 115°C, the residual carbon content is 58%, and the particle size is 0.8mm; Al in metal aluminum powder The content of SiC in silicon carbide fine powder is 99wt%, and the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com