Cement floor automatic hole grinding and stacking all-in-one machine and working method thereof

An all-in-one machine and palletizing technology, which is applied in the field of automatic grinding and palletizing machines for cement floors, can solve problems such as high risk factors, achieve the effects of large processing range, saving labor costs, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

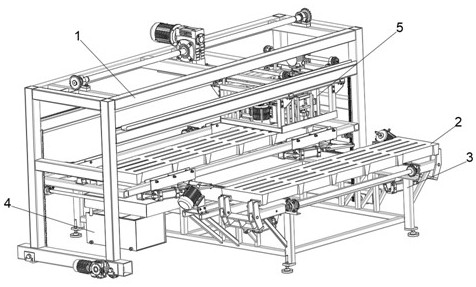

[0043] Such as Figure 1-10 As shown, the cement floor automatic grinding and palletizing machine includes a palletizing mechanism 1 , a positioning fixture 2 , a conveying mechanism 3 , a circulating water tank 4 and a grinding mechanism 5 .

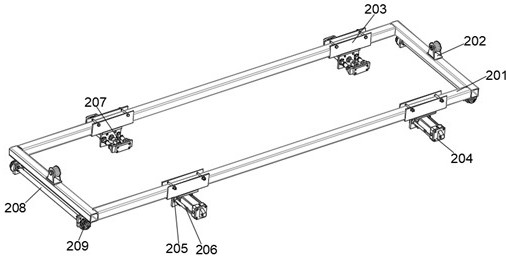

[0044] Such as figure 2 As shown, the palletizing mechanism 1 includes a frame 101, the lower sides of the front and rear ends of the frame 101 are respectively provided with a first rack 102 and a first guide rod 103, and the hole grinding mechanism 5 is provided with a first gear and a second guide sleeve 508, through the cooperation of the first gear and the second guide sleeve 508 with the first rack 102 and the first guide rod 103, the left and right movement of the hole grinding mechanism 5 is realized. The four columns at both ends of the frame 101 are provided with second racks 104 for the palletizing main frame 201 to move up and down synchronously. The top of the frame 101 is provided with a first reduction motor 109, the o...

Embodiment 2

[0051] The working method of the cement floor automatic grinding and palletizing machine includes the following steps:

[0052] Step 1: Set the parameters on the screen according to the size of the cement floor to be polished.

[0053] Step 2: Place the cement leaking manure floor on the end of the conveying mechanism 3 with the locking clip 306 through an external hoisting device.

[0054] Step 3: Press the start button, the second cylinder 305 of the conveying mechanism 3 works, the left and right locking clips 306 align the excrement leakage floor, and then the second cylinder 305 is released. The excrement leakage floor after finding the alignment begins to walk on the conveying line, and at this moment the trimming motor 515 work next to the locking clip 306, the edge trimming motor 515 is blunt with the edges and corners of the excrement leakage floor two ends.

[0055] Step 4: Continue to walk on the leaking excrement floor, and stop when it is in the middle position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com