Radiator for heat dissipation of high-calorific-value VPX plug-in

A heat-generating and radiator technology, applied in electrical components, structural parts of electrical equipment, modification by conduction and heat transfer, etc., can solve the problems of large total heat and concentrated heat sources, and achieve uniform temperature and low manufacturing cost. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

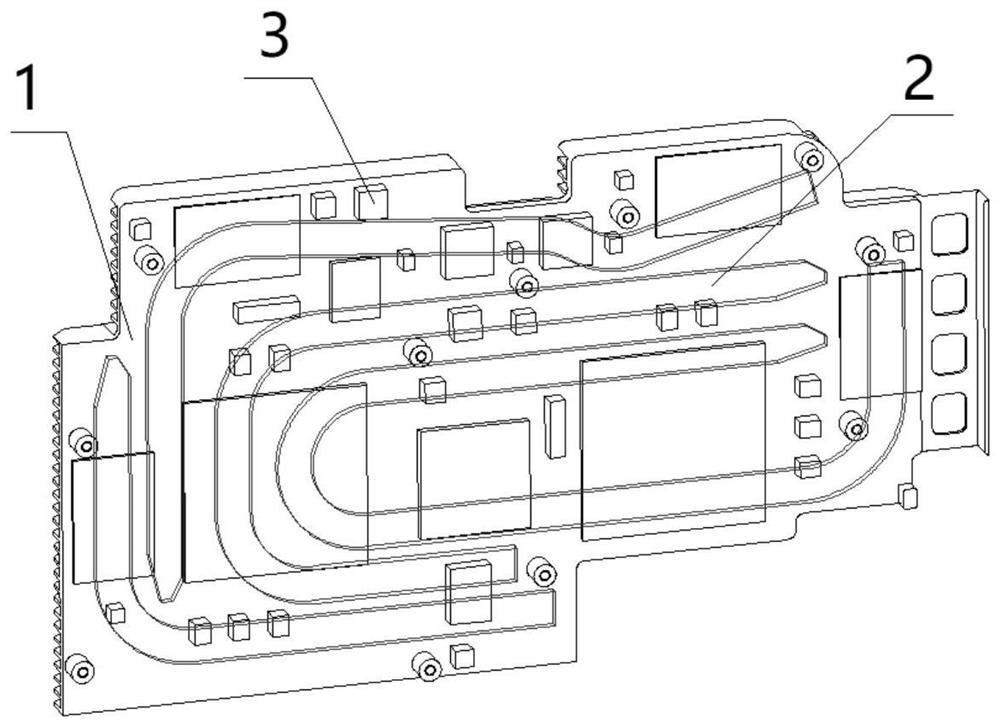

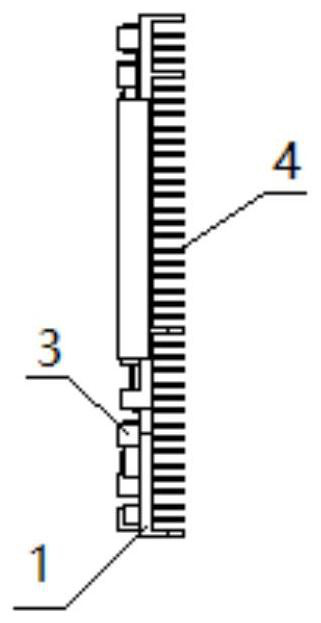

[0036] Such as figure 1 and figure 2 As shown, the present embodiment provides a heat sink for heat dissipation of a large calorific value VPX plug-in, including: a heat dissipation substrate 1 and a heat pipe 2 .

[0037] One side of the heat dissipation substrate 1 is provided with heat dissipation fins 4 . The heat pipe 2 is connected to the other surface of the heat dissipation substrate 1 .

[0038] Wherein, the heat pipe 2 is pasted on the other surface of the heat dissipation substrate 1 , and the heat pipe 2 can conduct the heat of the entire heat dissipation substrate 1 to realize uniform heat of the entire heat dissipation substrate 1 .

[0039] Wherein, the heat pipe 2 can be bent according to the need, so as to realize the omnidirectional lamination of the other surface of the entire heat dissipation substrate 1 . The heat pipe 2 can be a solid pipe or a hollow pipe, and can be set as a hollow pipe in order to save cost.

[0040] Wherein, the shape of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com