A hot-pressed tee tube blank zone heating and temperature control equipment and its heating and temperature control method

A technology for zoned heating and temperature control equipment, applied in metal extrusion control equipment, metal processing equipment, metal extrusion, etc., can solve problems such as pollution, non-energy saving, and affecting the overall performance of pipe fittings, and achieve the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments.

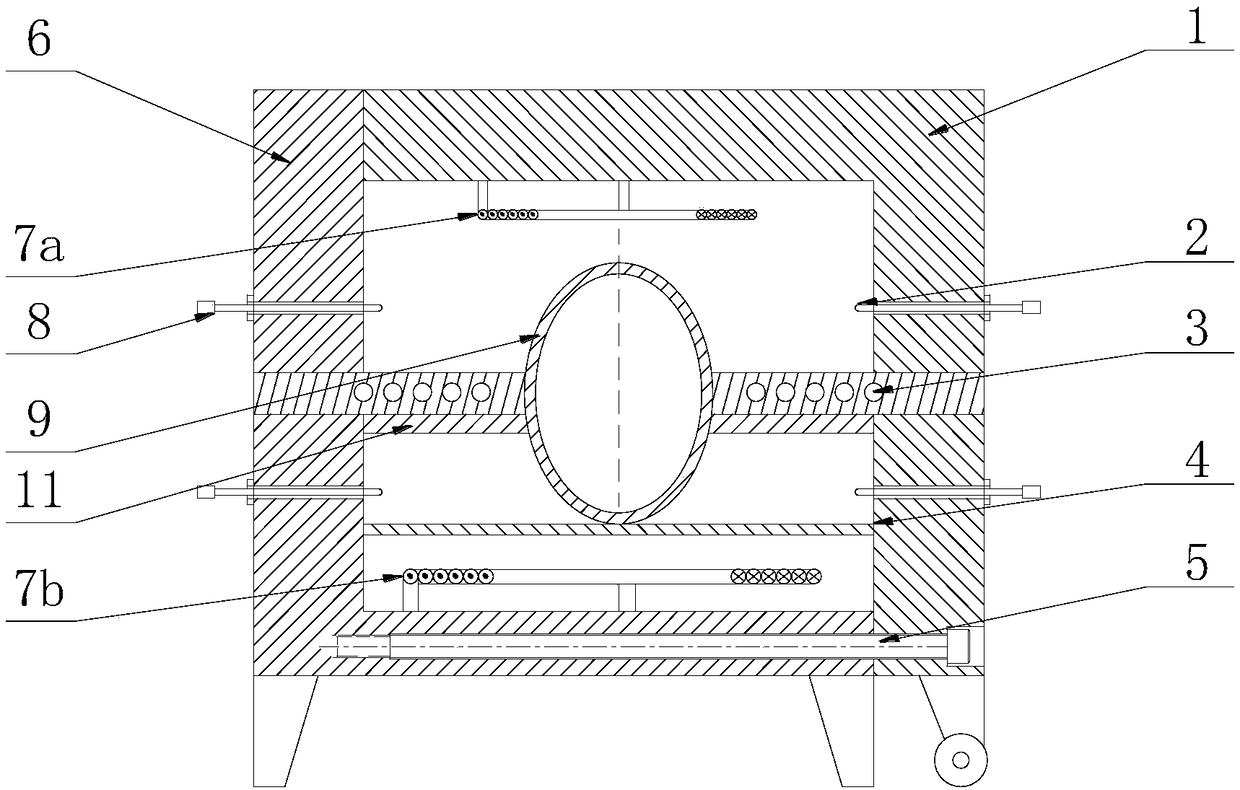

[0016] Such as figure 1 , figure 2 As shown, the hot-pressing three-way pipe billet heating and temperature control equipment in different regions includes L-shaped movable furnace base 1, L-shaped fixed furnace base 6 and induction eddy current heating device. There are three guide columns 5 under the L-shaped movable furnace base 1, Corresponding to the three guide post holes 10 of the L-shaped fixed furnace seat, the guide post 5 and the guide post holes 10 cooperate to play a guiding role when the furnace is combined. In the L-shaped movable furnace base 1, the upper and lower parts of the L-shaped fixed furnace base 6 are equipped with two pairs of infrared sensors 2 for sensing the internal temperature of the equipment. Both the L-shaped movable furnace base 1 and the L-shaped fixed furnace base 6 are equipped with a circulating water cooling device 3. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com