High-temperature compression molding process of aircraft engine nacelle inlet

An aircraft engine and engine nacelle technology, applied in the field of aircraft maintenance, can solve the problems of uniform distribution of conduction, limited effect of dehumidification methods, thermal recession of splicing edges, etc., to simplify the operation process, avoid construction risks, and shorten the engineering cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The following specific examples are listed to illustrate the present invention:

[0051]The high-temperature compression molding process of the air intake of the aircraft engine nacelle provided in this embodiment includes the following steps:

[0052] (1) Determine the damage type of the engine nacelle inlet, including the aging damage of the glued area and the large area of degumming damage including old repairs.

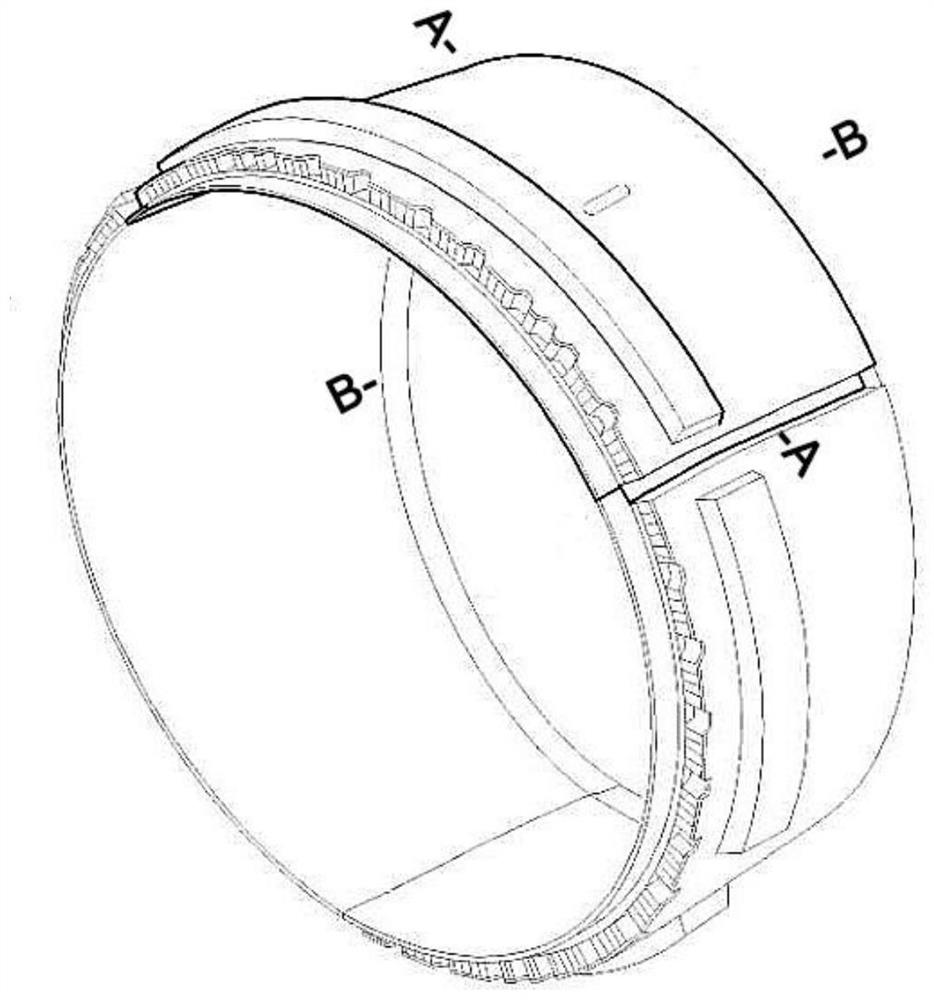

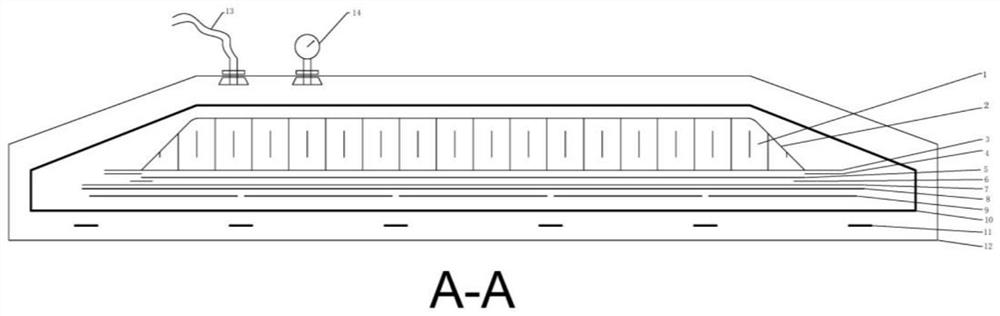

[0053] The air intake of the aircraft engine nacelle is the air intake of the V2500 aircraft engine nacelle, and the structure diagram of the air intake of the V2500 aircraft engine nacelle is shown in figure 1 As shown, it includes a honeycomb core 1, a carbon fiber 2, a carbon fiber skin 3 and a carbon fiber grid 4 from the inside to the outside in sequence, and the carbon fiber grid 4 is also provided with a wire mesh to be replaced.

[0054] (2) For the aging damage of the bonding area, low-density packing is used for isolation protection, and the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com