Power grid drilling construction process based on load-sensitive flexible control

A load-sensitive and construction technology, applied in drilling equipment and methods, automatic control systems for drilling, and earth-moving drilling, etc., can solve problems such as failure of the motor to drill, easy damage to the drill pipe, and adjustment of the torque and speed of the power head. , to achieve the effect of reducing engine emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate understanding, the present invention is further explained in detail below in conjunction with the examples.

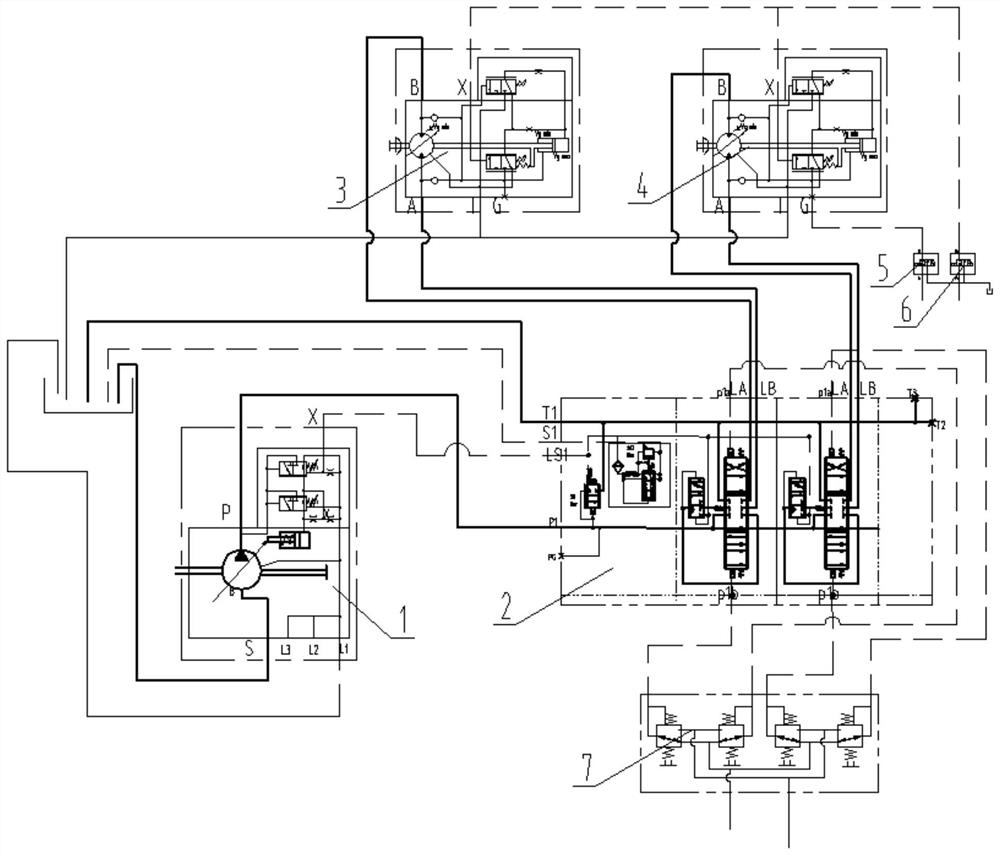

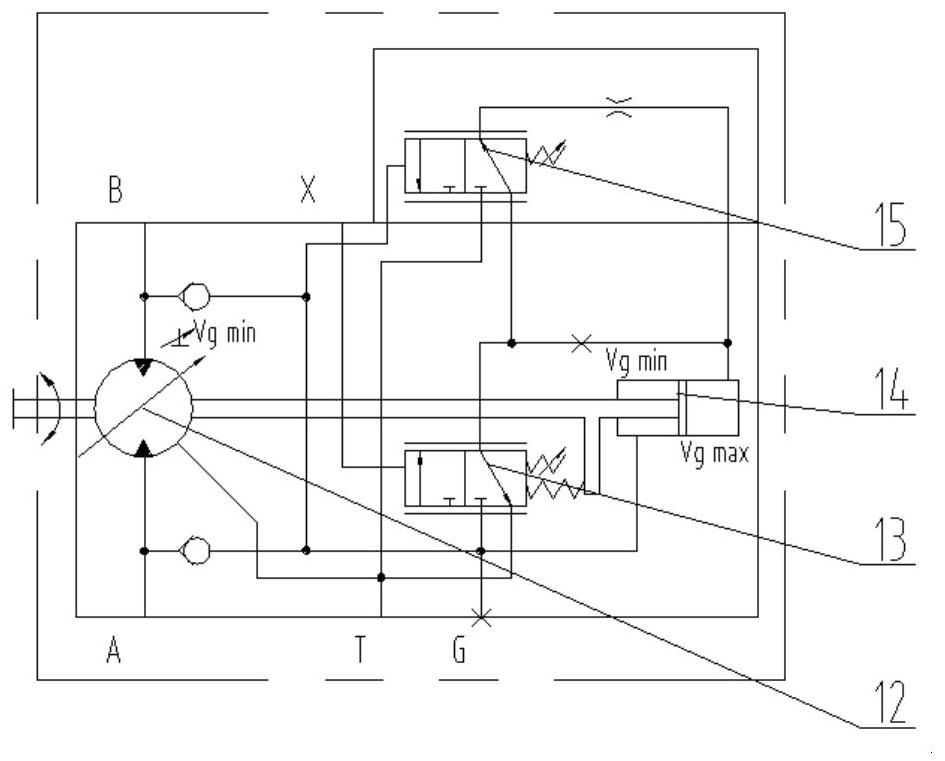

[0015] A power grid drilling construction technology based on load-sensing flexible control, which controls the work of the drill pipe through the load-sensing flexible control system, such as figure 1 As shown, the load sensitive flexible control system is mainly composed of variable regulating pump 1, load sensitive main valve 2, drill pipe power variable motor 3, drill pipe loading variable motor 4, high and low speed solenoid valve I5, high and low speed solenoid valve II6, remote hydraulic control The handle 7 and the corresponding high-pressure oil pipes (the solid line is the main oil circuit, and the dotted line is the control oil circuit) etc. are composed. The oil suction port of the variable regulating pump 1 is connected to the oil tank, the oil outlet of the variable regulating pump 1 is connected to the load sensitive main va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com