Shearing type STF damper

A damper and shear type technology, which is applied in the field of structural vibration reduction, can solve problems such as oil leakage, mismatch between design performance and actual performance, poor damper damping performance, etc., to solve the problem of limited frequency range and energy consumption, Efficient energy consumption effect, solving the effect of a large number of connectors and inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

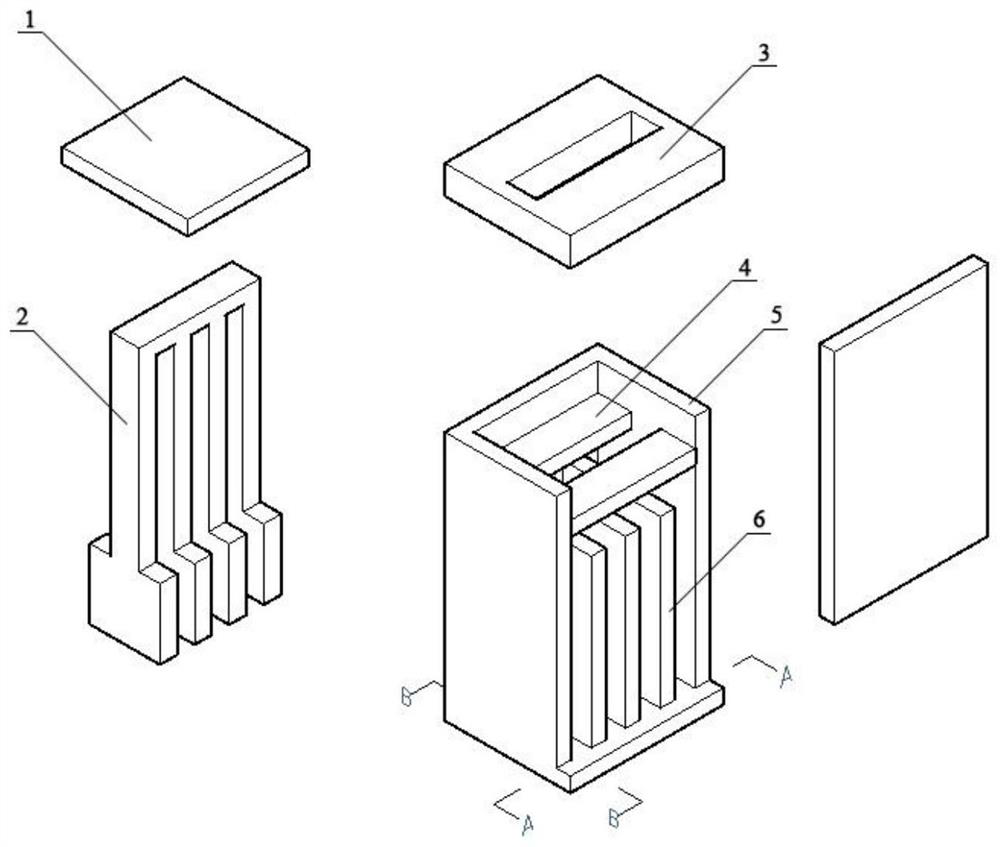

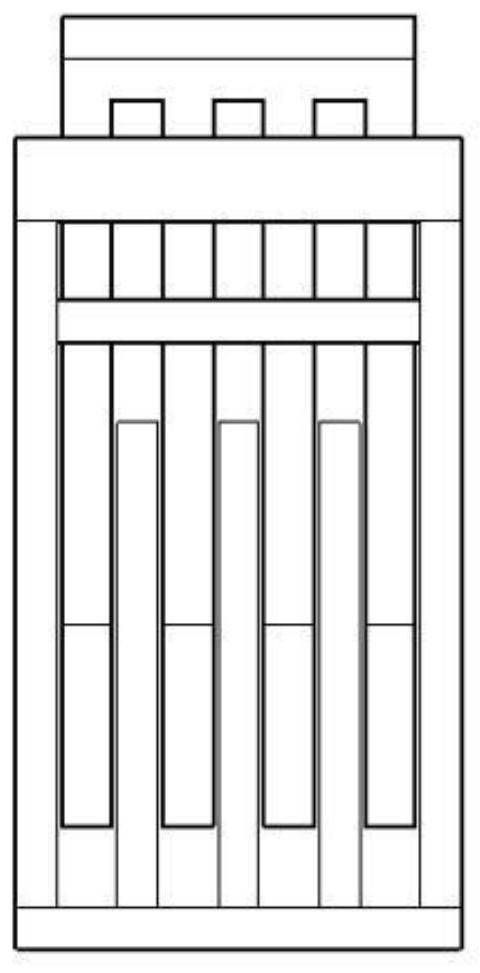

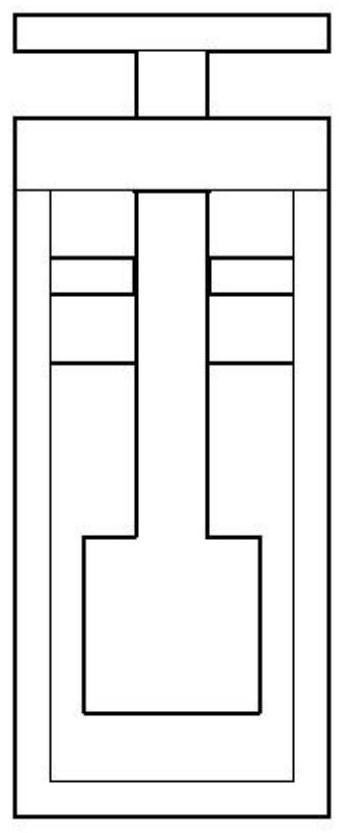

[0016] In order to make the purpose, features and advantages of the present invention more clear, the following will be combined with the appended Figure 1-3 , and further describe the technical solutions in the embodiments of the present invention.

[0017] A shear type STF viscous damper provided by the present invention comprises an upper connecting plate 1, steel teeth 2, an upper cover 3, a baffle plate 4, a steel sleeve 5, and a steel spacer 6; The steel sleeve 5 is a cuboid, which is integrated with the steel spacer 6 and can be welded; the internal baffle 4 and the sleeve 5 are not a whole, after the steel teeth 2 are put into the interior, adjust the position of the internal baffle Position, and then fixed (welded or bolted) to the side wall of the sleeve. After the baffle plate 4 is fixed, the upper cover 3 is connected (welded or bolted) to the upper part of the steel sleeve 5, and a certain space is left between the upper cover 3 and the baffle plate 4 to facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com