Preparation method of desalted cartilage oligopeptide powder

An oligopeptide and cartilage technology, applied in the field of preparation of desalted cartilage oligopeptide powder, can solve problems such as high consumption of pure water, and achieve the effects of reducing sewage discharge, simple operation process and improving product value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

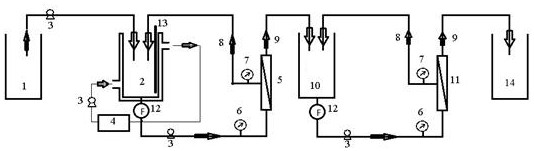

Method used

Image

Examples

Embodiment 1

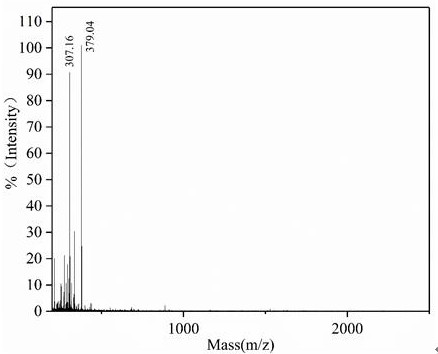

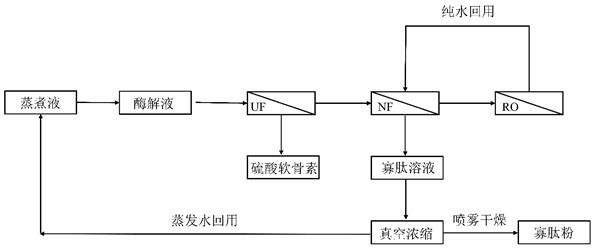

[0034] Accurately weigh 300g of porcine cartilage and 600g of porcine trachea, wash off the surface dirt with water, then add water for continuous cooking for 5 hours, cool down to 52°C, add 30g of porcine pancreas, and add 2g of NaOH several times to adjust the pH to 8.50-9.00 , maintaining the temperature at 52 °C for 2.5 h. Weigh 1.70g alkaline protease for the second enzymolysis, add 2g NaOH several times to adjust the pH to 8.50-9.00, keep the pH in this range throughout the enzymolysis process, keep the temperature at 52°C, and enzymolysis for 5 hours, Then after inactivation and filtration, it enters the ultrafiltration membrane equipment with a molecular weight cut-off of 5000Da, so that the chondroitin sulfate and oligopeptide solution can be effectively separated, and the separated protein material liquid enters the polyamide nanofiltration membrane equipment with a molecular weight cut-off of 150-300Da. Concentrate the oligopeptide solution to the minimum volume and...

Embodiment 2

[0036] Accurately weigh 350g of chicken cartilage and 650g of duck trachea, wash off the surface dirt with water, then add water to continue cooking for 4-6 hours, cool down to 48°C, add 28g of pig pancreas, and continue to stir at 120rpm, adding in several times 2.5 g NaOH adjusted the pH to 8.50-9.00 and kept the temperature at 48 °C for 2 h. Weigh 1.50g of alkaline protease for the second enzymolysis, adjust the pH to 8.50-9.00, keep the pH in this range throughout the enzymolysis process, keep stirring during the enzymolysis process, so that the enzymolysis is sufficient and the process temperature is always Keep at about 50°C, enzymatically hydrolyze for 4 hours, then stop stirring, inactivate and filter the feed liquid into the ultrafiltration membrane equipment with a molecular weight cut-off of 5000Da, so that the chondroitin sulfate and oligopeptide solution can be effectively separated, and the separated protein feed liquid Enter the polyethersulfone nanofiltration m...

Embodiment 3

[0038] Accurately weigh 450g of duck cartilage and 550g of pig trachea, wash off the surface dirt with water, then add water for continuous cooking for 3-5 hours, cool down to 50°C, add 30g of pig pancreas, and add 3 g of NaOH several times to adjust the pH to 8.50-9.00, keep the temperature at 50°C for 2h. Weigh 1.85 g of alkaline protease for the second enzymolysis, adjust the pH to 8.50-9.00, keep the pH in this range throughout the enzymolysis process, keep the temperature at 50°C, enzymolysis for 4 hours, add 17 g of hydrochloric acid, hydrogen peroxide 3.00g, inactivated, filtered through a double-layer 400-mesh filter, the feed liquid enters the ultrafiltration membrane equipment with a molecular weight cut-off of 4000Da, so that the chondroitin sulfate and oligopeptide solution can be effectively separated, and the separated protein feed liquid enters the molecular weight cut-off of 200Da The cellulose acetate nanofiltration membrane equipment is used to concentrate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com