Anti-sloughing drilling fluid as well as preparation method and application thereof

A drilling fluid, plugging and anti-collapse technology, which is applied in the field of petroleum drilling, can solve problems that affect the safety of downhole drilling, complex jamming, and stratum collapse, and achieve the effect of reducing poor drilling, reducing jamming, and unobstructed wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

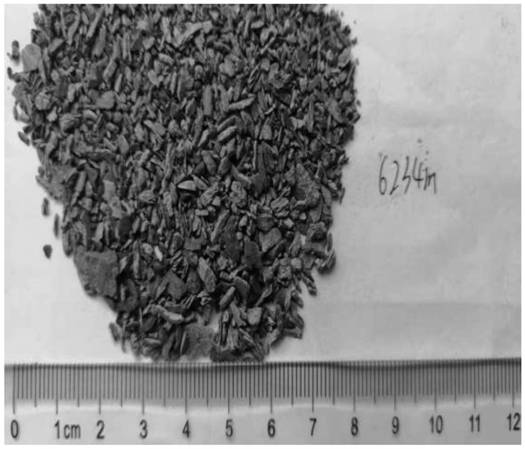

[0057] This example relates to an anti-slump drilling fluid suitable for safe drilling in fractured carbonate formations. The components are calculated in parts by weight, including 1000 parts of water, 30 parts of sodium bentonite, and 4 parts of polymer fluid loss control. Agent PAC-L V (Zhengzhou Dongfang Auxiliary Co., Ltd.), 30 parts of lignite resin SPNH (Kunming Jinsida Chemical Co., Ltd.), 30 parts of sulfomethyl phenolic resin SMP-2 for drilling fluid (Zhengzhou Dongfang Auxiliary Co., Ltd.), 5 parts NaOH, 20 parts of superfine calcium carbonate, 15 parts of SMNP-1 (particle size is 0.1 ~ 10 μm, Sinopec Petroleum Engineering Technology Research Institute), 20 parts of SM-Shield-2 (Sinopec Petroleum Engineering Technology Research Institute), 20 parts SMNA-1, 20 copies of SMCG-2 (Sinopec Petroleum Engineering Institute), 4 copies of SMTQ-1 (Sinopec Petroleum Engineering Technology Institute), 3 copies of FA367 (Jinan Haofeng Chemical Co., Ltd.), 30 copies of SMJH-1 (Chi...

Embodiment 2

[0063] This example relates to an anti-slump drilling fluid suitable for safe drilling in fractured carbonate rock formations. The components include 1000 parts by weight of water, 25 parts of sodium bentonite, and 6 parts of SMPFL-L (China Petrochemical Petroleum Engineering Technology Research Institute), 30 parts of SPNH, 30 parts of SMP-2, 6 parts of NaOH, 25 parts of ultrafine calcium carbonate, 15 parts of SMNP-1, 20 parts of SMLS-1 (Sinopec Petroleum Engineering Technology Research Institute), 20 parts of SMNA-1, 25 parts of SMCG-2, 3 parts of SMTQ-1, 3 parts of FA367, 30 parts of SMJH-1, 630 parts of barite. The superfine calcium carbonate particle size is mixed in three equal weight ratios of 500 mesh, 800 mesh and 2500 mesh. All components are commercially available products.

[0064] The specific preparation method of this example is: first dissolve 25 parts of sodium bentonite in 1000 parts of water, stir at 500r / min for 24 hours to fully hydrate, and after hydrat...

Embodiment 3

[0069] This example relates to an anti-slump drilling fluid suitable for safe drilling in fractured carbonate formations. The components include 1000 parts of water, 15 parts of sodium bentonite, 6 parts of SMPFL-L, and 35 parts by weight. Parts SPNH, 35 parts SMP-2, 6 parts NaOH, 30 parts superfine calcium carbonate, 10 parts SMNP-1, 20 parts SMNA-1, 20 parts SMLS-1, 25 parts SMCG-2, 4 parts SMTQ-1, 3 parts of KPAM, 30 parts of SMJH-1, 1300 parts of barite. The superfine calcium carbonate particle size is mixed by equal weight ratio of 800 mesh and 2500 mesh. All components are commercially available products.

[0070] The specific preparation method of this example is: first dissolve 15 parts of sodium bentonite in 1000 parts of water, stir at 500r / min for 24 hours to fully hydrate, and after hydration, add 6 parts of SMPFL-L to the soil slurry under the condition of 8000r / min Fully dissolved in the medium, followed by 35 parts of SPNH, 35 parts of SMP-2, 6 parts of NaOH, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com