Thiourethane polymers, method of synthesis thereof and use in additive manufacturing technologies

A urethane, polymer technology for tooling, additive manufacturing, additive processing, etc. that solves problems such as poor mechanical properties, long print times, and limited 3D part performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

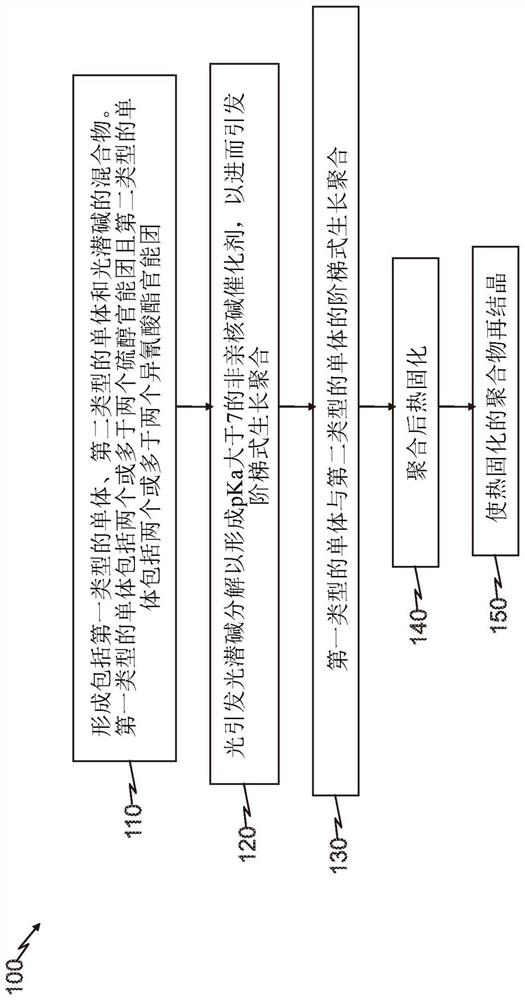

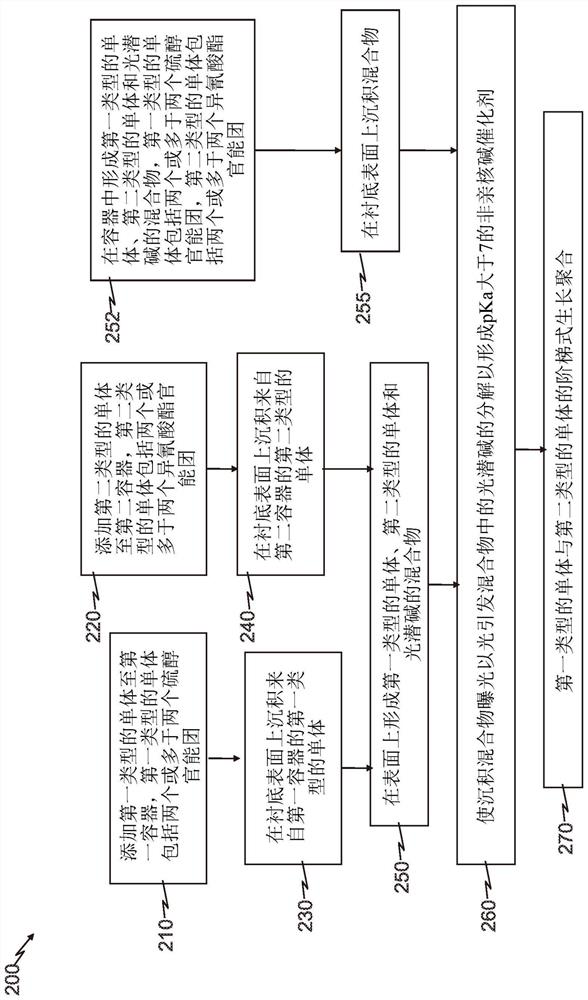

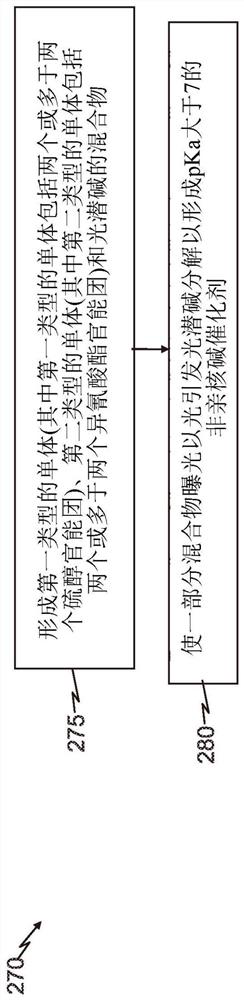

[0024] Embodiments of the present invention benefit from the discovery that semi-crystalline thiourethane polymers can be synthesized from compounds containing two or more thiol functional groups via a rapid anionic step-growth polymerization mechanism in the presence of photolatent bases. Synthesized from a mixture of monomers of the first type and monomers of the second type with two or more isocyanates, the photolatent base decomposes upon photoinitiation to form a non-nucleophilic base with a pKa greater than 7.

[0025] The fast reaction rate of thiol-isocyanate coupling achieved by this combination of monomers and non-nucleophilic base catalysts makes this thiol click polymerization chemistry ideal for providing application specific materials such as (but not limited to) impact resistant materials, 3D printing resins , bioimplantable materials or protective coatings.

[0026] One embodiment of the present disclosure is a semi-crystalline thiourethane polymer. Semi-cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com