Methanol cooling and recycling process

A cooling recovery, methanol technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of increasing methanol consumption, huge energy consumption, low recovery efficiency, etc., to achieve less consumption of circulating water, smooth heat transfer, and energy saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

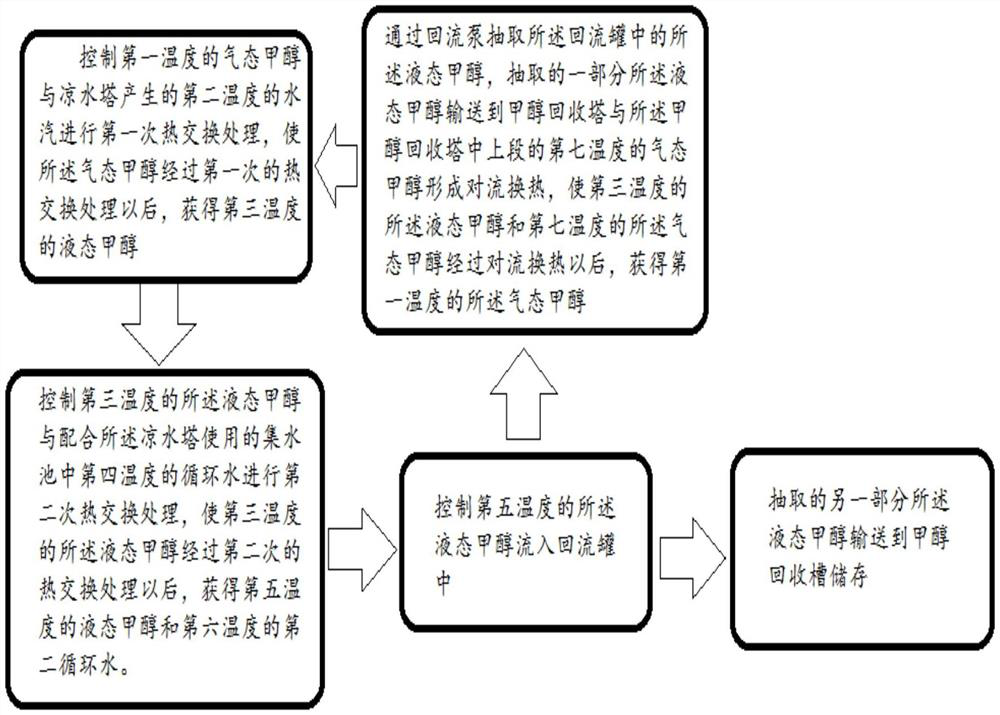

[0028] Such as figure 1 Shown, a kind of methanol cooling recovery process, comprises the following steps: the gaseous methanol of the first temperature and the water vapor of the second temperature produced by the cooling tower are subjected to the heat exchange treatment for the first time, and the gaseous methanol is subjected to the heat exchange for the first time After treatment, liquid methanol at a third temperature is obtained.

[0029] The working principle of the above-mentioned technical scheme is as follows:

[0030] Through the first heat exchange treatment between the gaseous methanol at the first temperature and the water vapor at the second temperature generated by the cooling tower, the gaseous methanol is converted into liquid methanol, causing a phase change between gaseous methanol and liquid methanol. This phase change process requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com