Anti-freezing hydraulic cylinder structure with ice scraping device

A hydraulic cylinder and ice device technology, applied in the field of hydraulic cylinder structure, can solve the problems of non-adjustable moving speed, affecting the life of the element, and low tracking accuracy, so as to eliminate the impact, prolong the service life, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

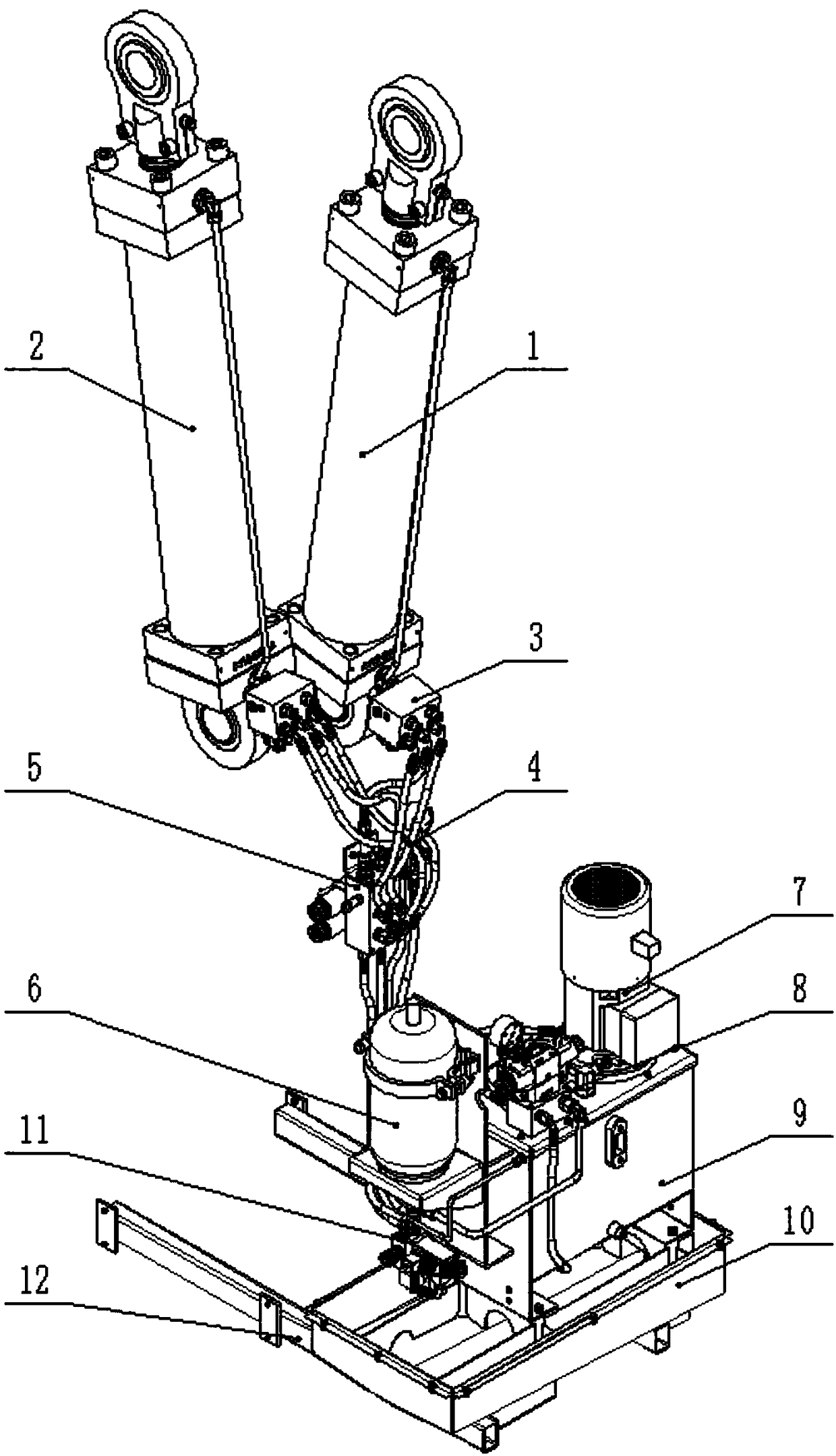

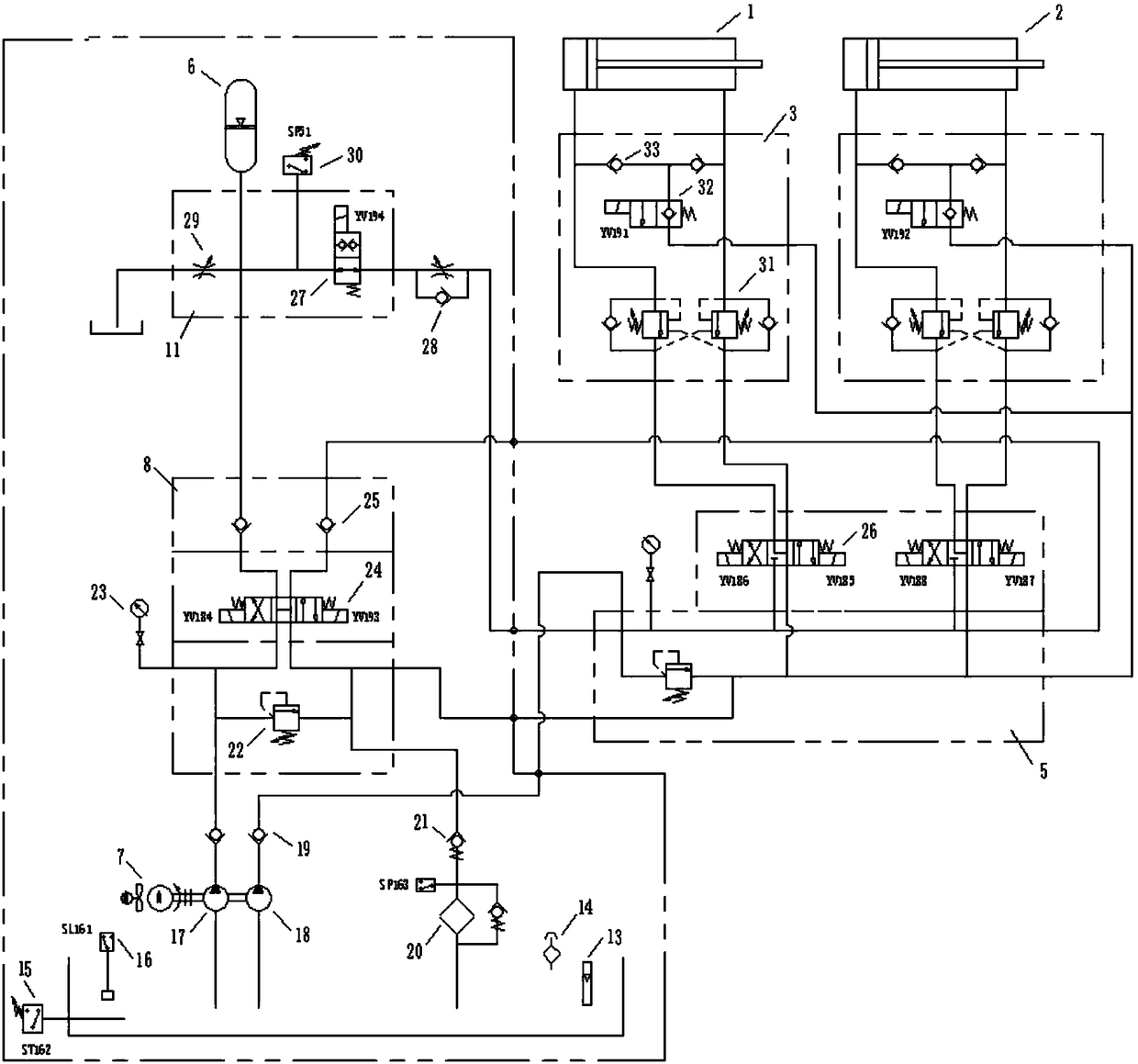

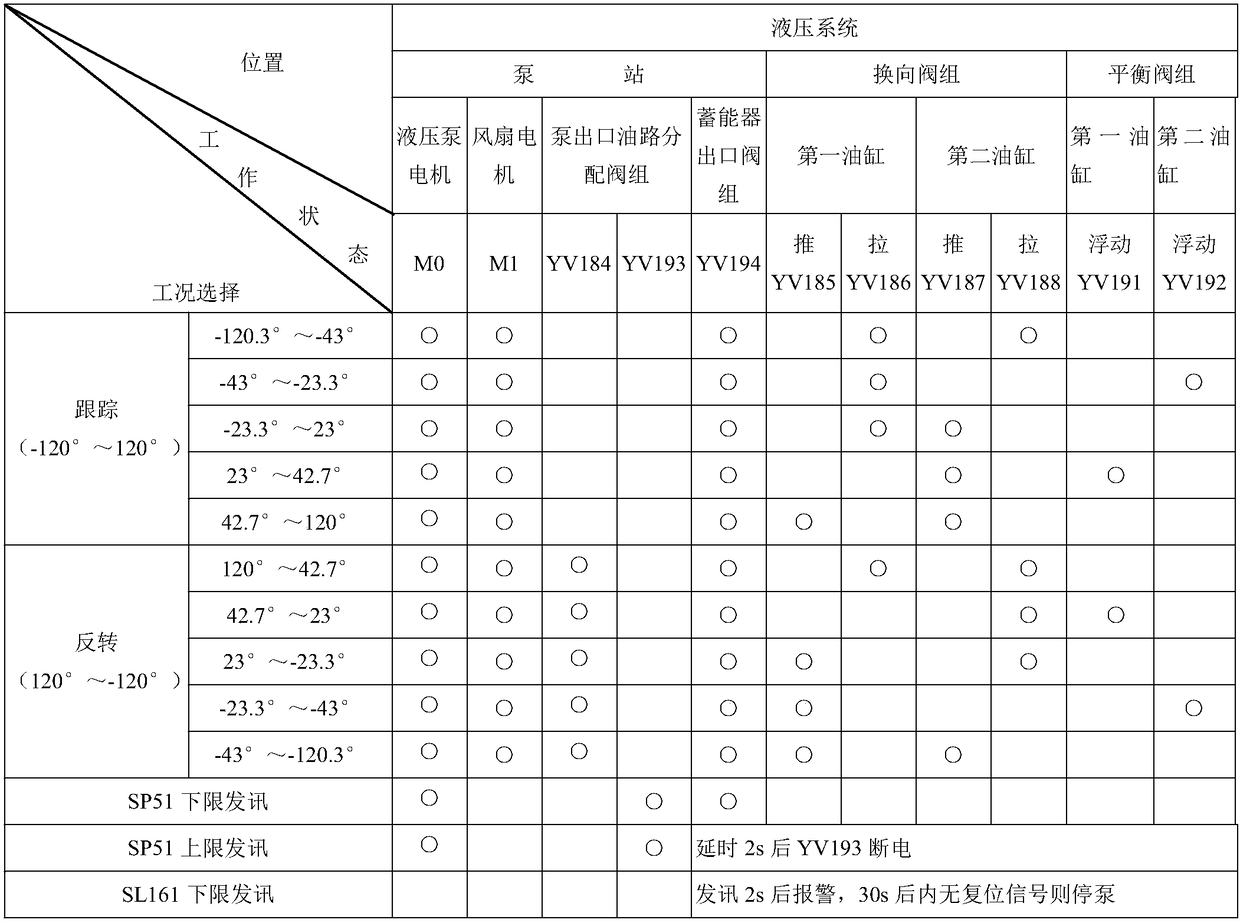

[0014] As shown in the figure, hydraulic oil tank 9, motor 7, pump outlet oil circuit distribution valve group 8, reversing valve group 5, balance valve group 3, first oil cylinder 1, second oil cylinder 2, accumulator 6 and energy storage The outlet valve group 11 of the hydraulic oil tank is provided with a distribution valve group of motor and pump outlet oil circuit, an accumulator is arranged on one side of the hydraulic oil tank, and an accumulator outlet valve group is arranged under the accumulator. The outlet valve group of the pump is connected with the distribution valve group of the pump outlet oil circuit, the distribution valve group of the pump outlet oil circuit is connected with the reversing valve group, and the reversing valve group is respectively connected with the first oil cylinder and the second oil cylinder, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com