A single-cycle hybrid cooling system and cooling method for a marine diesel engine

A marine diesel engine, hybrid cooling technology, applied in engine cooling, coolant flow control, mechanical equipment, etc., can solve the problems of high fuel consumption rate, unfavorable combustion, poor economic performance, etc., to achieve low fuel consumption rate, High effective efficiency and good economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

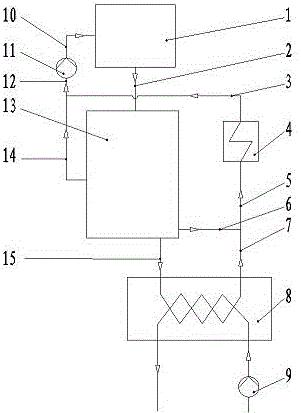

[0022] The present invention is described with reference to the drawings and specific embodiments.

[0023] Such as figure 1As shown, a single-cycle hybrid cooling system for a marine diesel engine, the cooling system includes a fresh water pump 11, a sea water pump 9, a temperature regulating device 13, a heat exchanger 8, an air cooler 4 and each connecting pipeline; The fresh water pump 11 is installed on one side of the transmission end of the diesel engine to provide the driving force required for cooling water circulation; the seawater pump 9 is installed on the other side of the transmission end of the diesel engine to provide the required driving force for seawater circulation; the air cooler 4 is installed at the output end of the diesel engine, and is a device for heat exchange between pressurized air and cooling water; the heat exchanger 8 is installed at the transmission end of the diesel engine, and is a device for heat exchange between cooling water and seawater;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com