Disassembling and assembling tool for valve seats of cone valves of diaphragm pump

A technology for disassembling and assembling tools and diaphragm pumps, which is applied in the manufacture of tools and hand-held tools, etc., which can solve the problems of low efficiency, time-consuming and laborious, etc., and achieve the effects of convenient operation, reduced strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

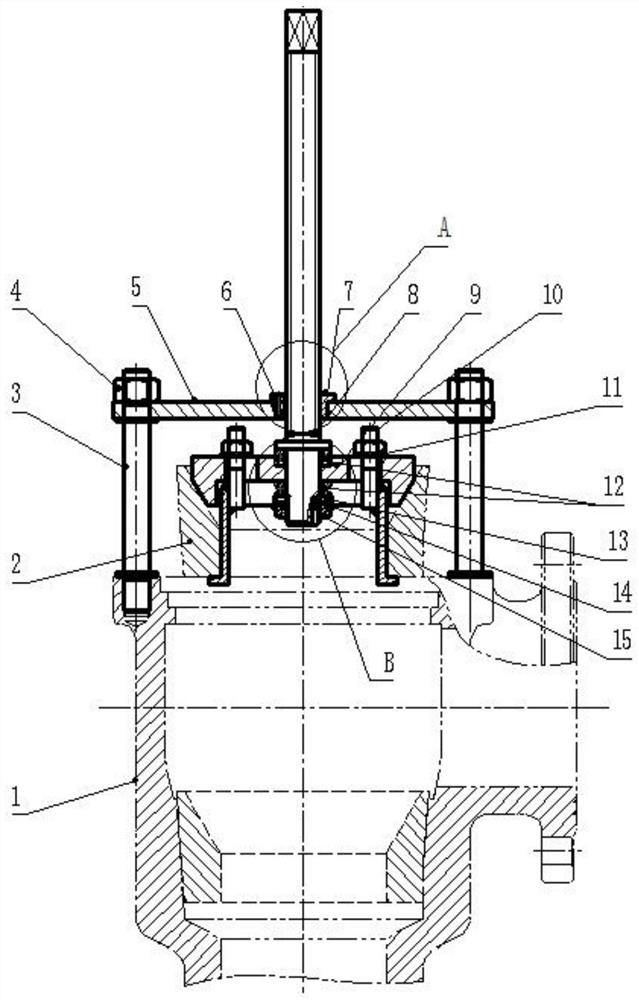

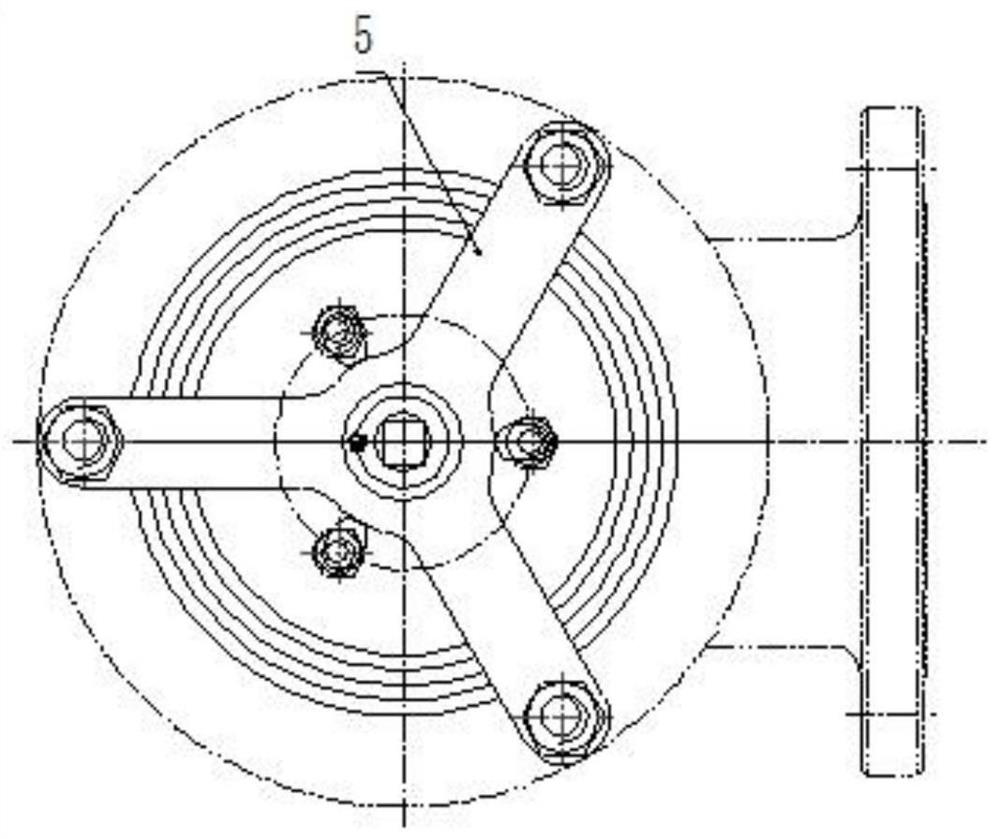

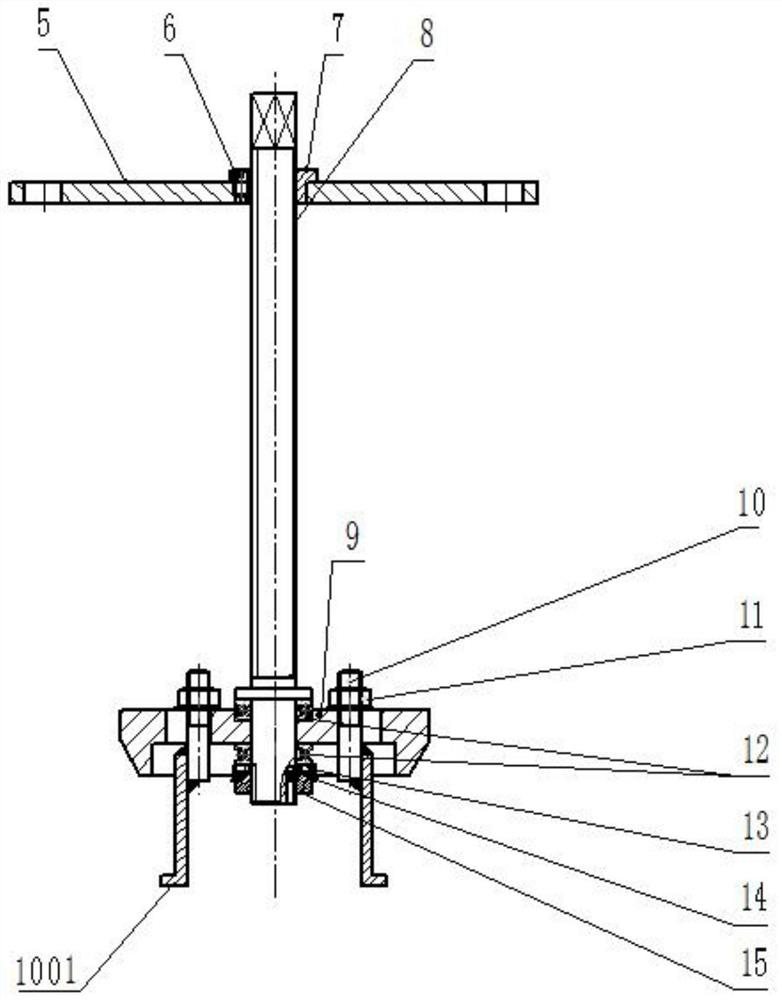

[0027] from Figure 1-3 It can be seen that the assembly and disassembly tool for a cone valve seat of a diaphragm pump in this embodiment includes a beam frame 5, a screw rod 8 is installed in the middle of the beam frame 5, and one end of the screw rod 8 runs through the beam frame 5 and is connected with a valve. Seat pressing block 9, the surface of valve seat pressing block 9 is provided with pull rod 10 at intervals, one side end of pull rod 10 is provided with pull rod nut 11, and pull rod 10 is locked with valve seat pressing block 9 through pull rod nut 11.

[0028] The bottom of the beam frame 5 is connected with a cone valve box 1, and the surface of the cone valve box 1 is provided with a valve seat 2.

[0029] The beam frame 5 is in the shape of a trident frame, and is made of steel plate. The central axis of the beam frame 5 is provided with screw holes, and the trident ends of the beam frame 5 are evenly arranged with bolt holes. The column bolts 3 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com