Brake pad disassembling device

A technology of brake pads and movement, applied in the direction of brake parts, manufacturing tools, hand-held tools, etc., can solve problems such as difficulty in disassembling the brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

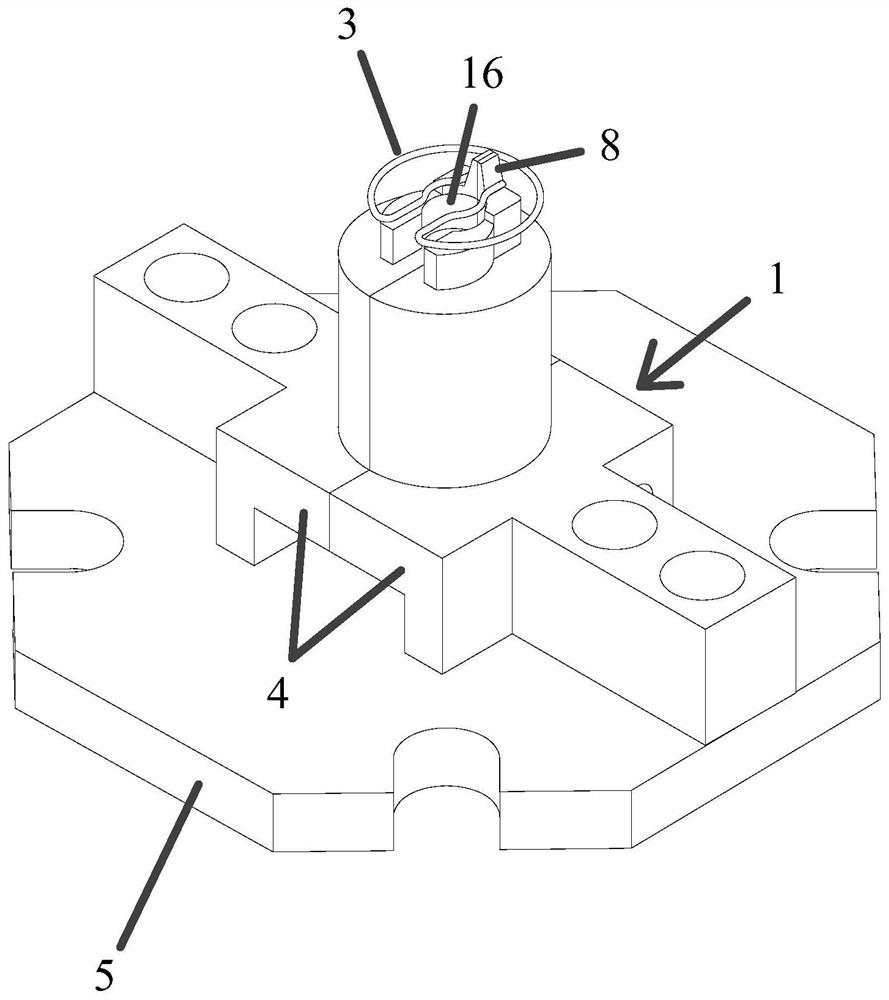

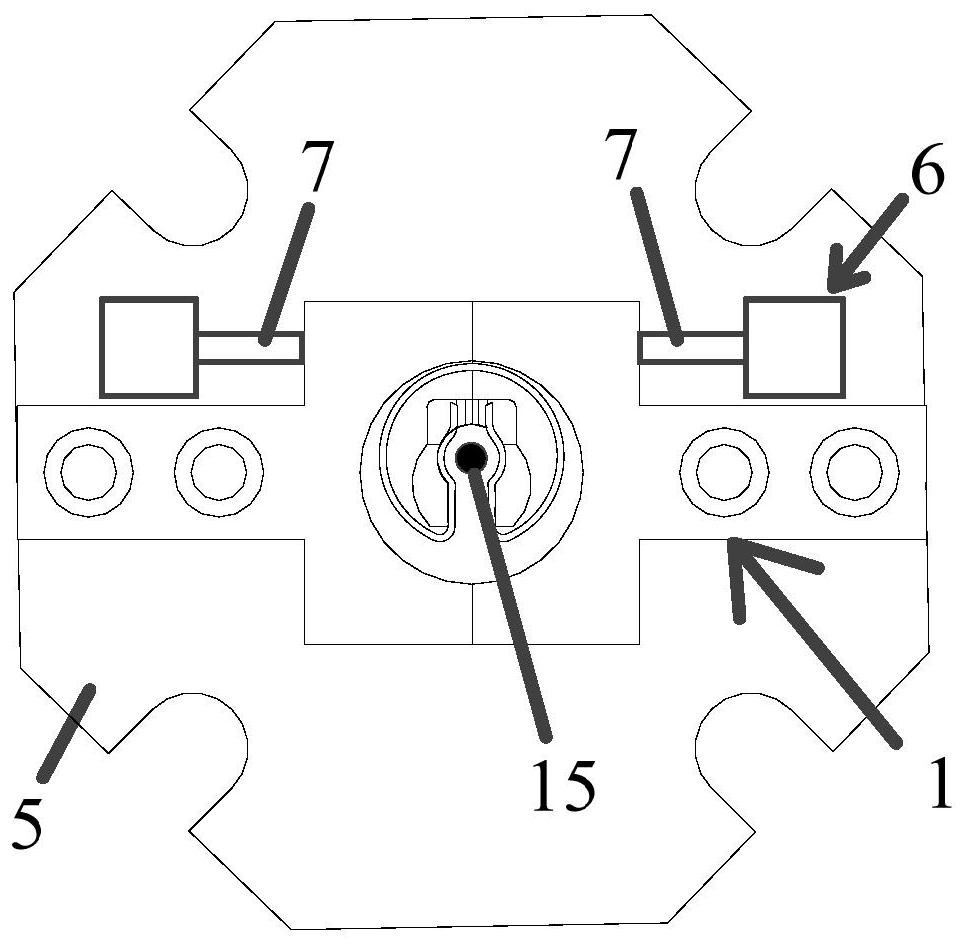

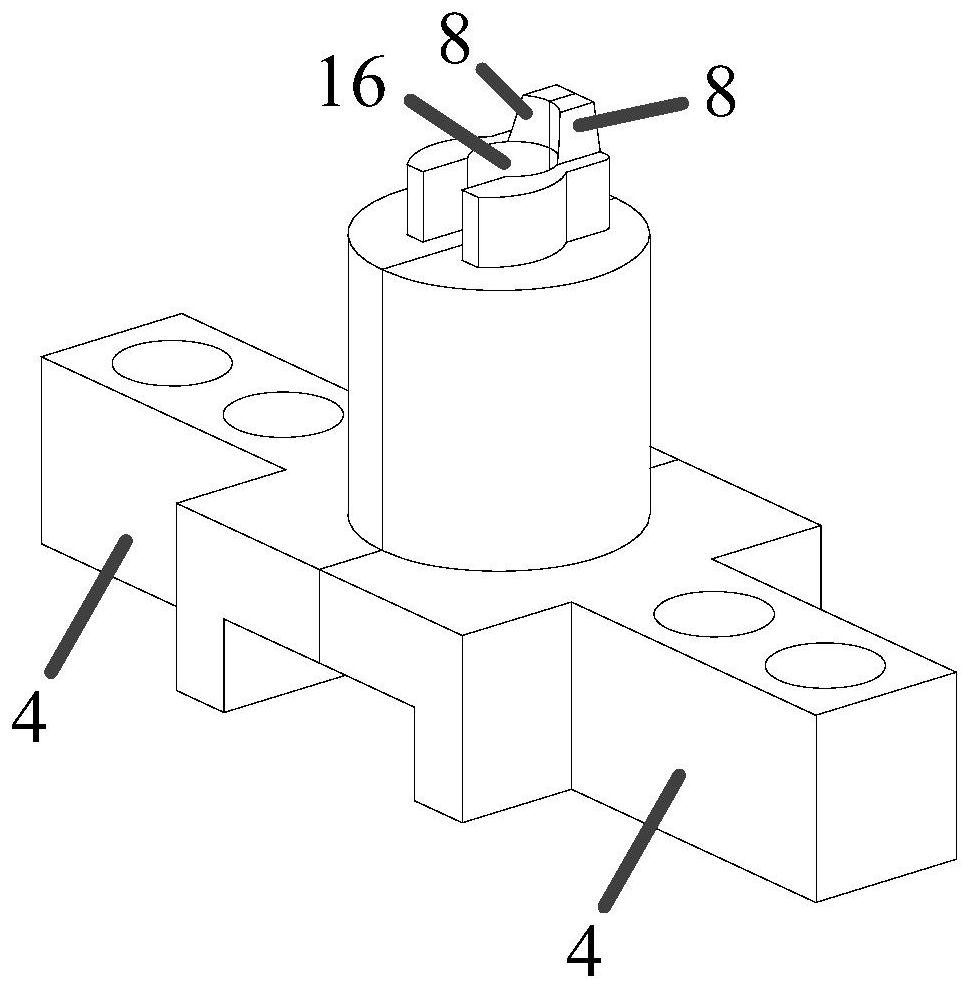

[0049] A brake pad dismantling device is described, such as figure 1 shown, including:

[0050] The opening and closing claw 1, the opening and closing claw 1 is adapted to the shape of the clip spring 3 of the brake pad 2, and the opening and closing claw 1 includes oppositely arranged and driven to move toward or away from each other. Clamping part 4; such as Figure 4 and Figure 5 As shown, in this example as Image 6 As shown, the snap ring 3 includes an outer ring 9, an inner ring 10, and two extensions 11 located on the inner ring 10 and oppositely arranged; as figure 2 and image 3 As shown, the engaging portion 4 is connected to the extension portion 11 to drive the two extension portions 11 away from each other. Through the above-mentioned opening and closing claw 1, it can be precisely connected with the brake pad 2 and its clip spring 3, and the clip spring 3 will be moved during the opposite movement of the two oppositely arranged snap-in parts 4 that make u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com