A kind of equipment for dismantling nuts of petroleum machinery and equipment

A petroleum machinery and equipment technology, applied in the field of petroleum machinery and equipment nut disassembly and assembly equipment, can solve the problems of high labor intensity, affecting the production and economic benefits of enterprises, and low work efficiency, and achieve high disassembly and assembly efficiency, low disassembly and assembly efficiency Fast, easy-to-reach results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

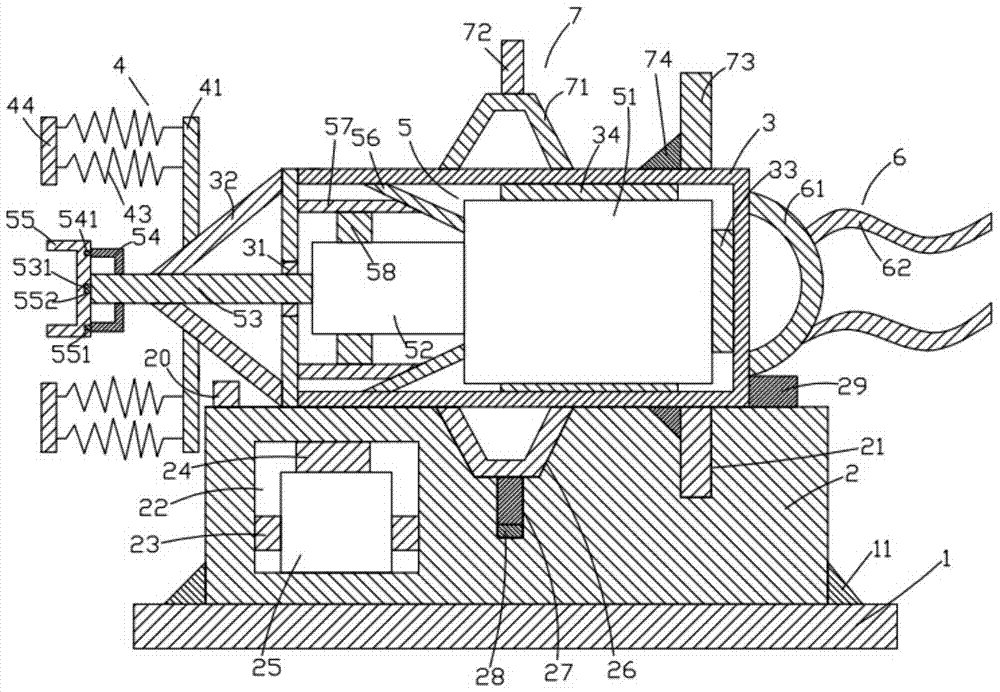

[0018] Such as figure 1 As shown, the present invention includes a bottom plate 1, a support seat 2 above the bottom plate 1, a frame body 3 above the support seat 2, and a support seat on the left side of the frame body 3. The device 4 , the motor device 5 located in the frame body 3 , the first holding device 6 located on the right side of the frame body 3 , and the second holding device 7 located on the upper and lower sides of the frame body 3 .

[0019] Such as figure 1 As shown, the base plate 1 is a cuboid, the base plate 1 is placed horizontally, the base plate 1 is provided with a first fixing block 11, and the first fixing block 11 is provided with two and are located on the left and right sides respectively. The cross section of the first fixing block 11 is triangular in shape, and the lower surface of the first fixing block 11 is fixedly connected with the upper surface of the bottom plate 1 .

[0020] Such as figure 1 As shown, the support base 2 is a cuboid, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com