Vegetable market garbage crusher

A pulverizer and vegetable market technology, which is applied in the direction of dryers, presses, local agitation dryers, etc., can solve the problems of increased labor intensity, low drying efficiency, and unfavorable product quality, so as to achieve easy storage and use, Improves crushing efficiency and facilitates drying and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

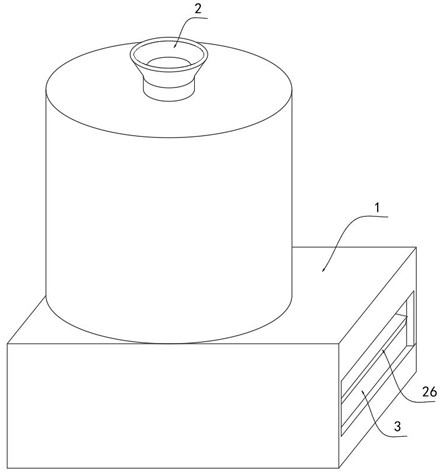

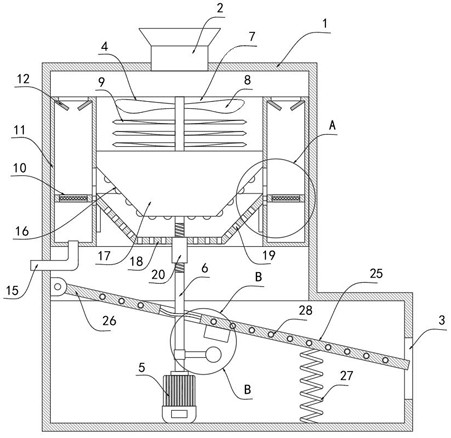

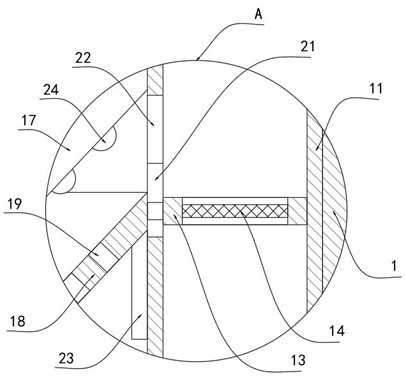

[0029] Such as Figure 1-5 As shown, a garbage shredder for a vegetable market includes a body 1. It should be noted that the body 1 is composed of a cylindrical cylinder and a box. The cylinder and the box are fixed and communicated. The top of the body 1 is provided with Feeding hopper 2, the vegetable market garbage to be crushed is put into the machine body 1 from the feeding hopper 2, the bottom side wall of the machine body 1 is provided with a discharge port 3, and the machine body 1 is provided with a crushing and cleaning device 4, which is a crushing and cleaning device 4 It includes a motor 5 fixedly arranged on the inner bottom surface of the body 1, the output shaft of the motor 5 is connected with a rotating shaft 6, a cleaning chamber 7 is arranged in the body 1, and cleaning water is filled in the cleaning chamber 7, and the liquid level of the cleaning water is equal to the ring squeeze The upper end surface of the pressure box 11 is flat, and supplementary cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com