Non-ferrous metal ore pre-dressing and waste discarding method

A non-ferrous metal and fine ore technology, applied in solid separation, grain processing, etc., can solve the problems of large metal loss, low recovery rate of non-ferrous metal ore, low accuracy, etc., to achieve small metal loss, high degree of automation, The effect of high beneficiation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] pair containing WO 3 0.309% wolframite raw ore is pre-selected and discarded, the steps are as follows:

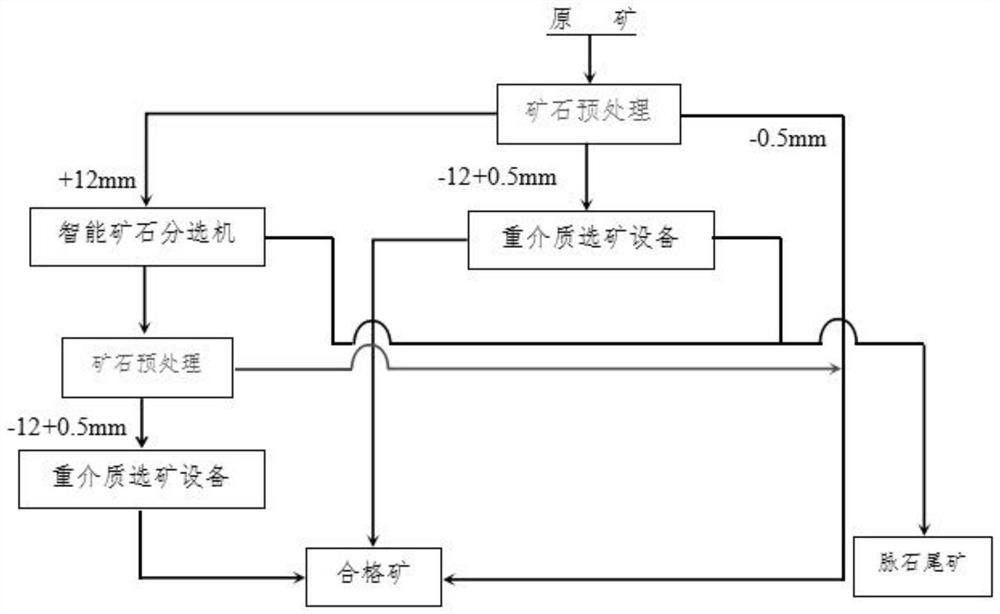

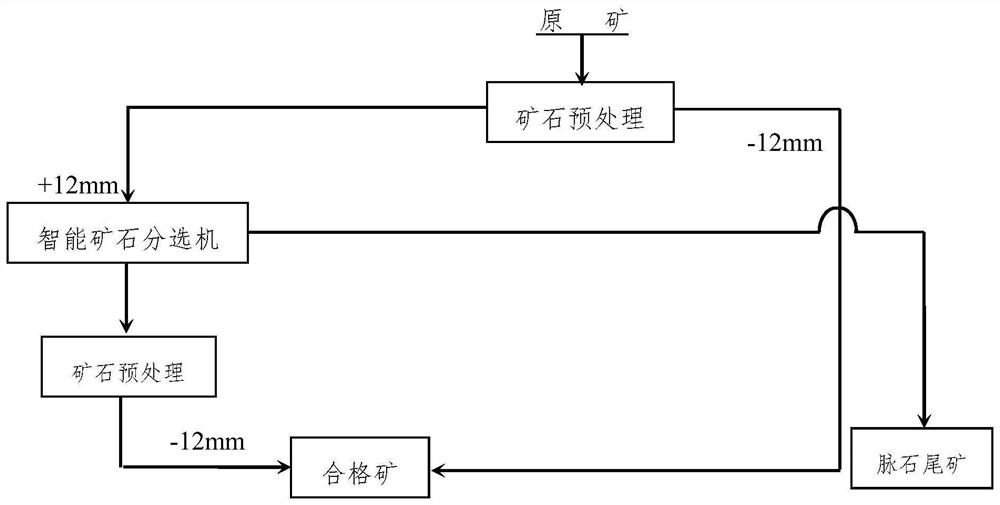

[0064] (1) After crushing the wolframite raw ore to -80mm, carry out screening and classification pretreatment, and divide it into three grades of -80+12mm, -12+0.5mm and -0.5mm, of which -0.5mm grade products are directly used as Qualified mine;

[0065] (2) Use an intelligent ore sorting machine to pre-select and discard the -80+12mm grain grade products to obtain rough concentrates, crush the obtained rough concentrates to -12mm, and then screen and classify them into -12+0.5mm and -0.5mm; Among them, -0.5mm grain size products are directly regarded as qualified ore;

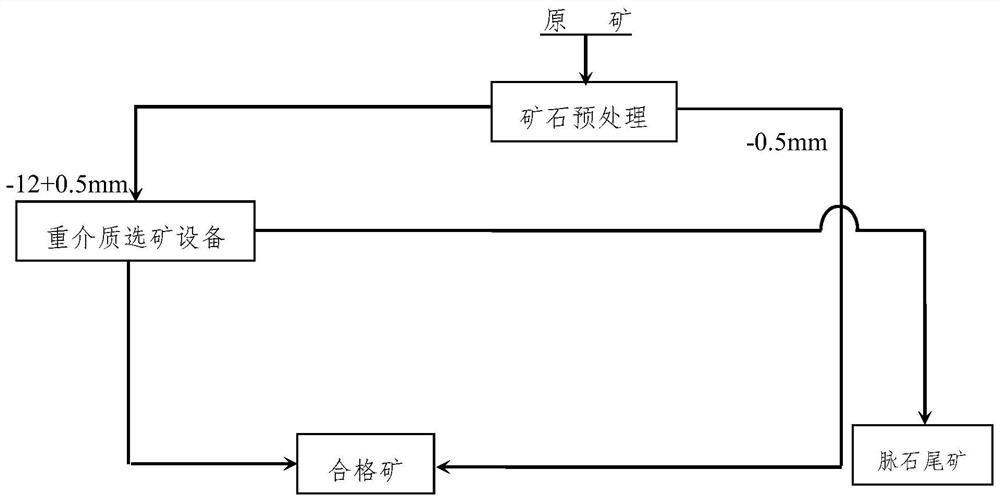

[0066] (3) The -12+0.5mm particle size product obtained in step (1) and step (2) is pre-selected and discarded by dense medium beneficiation equipment. 0.5mm, the obtained concentrate is regarded as qualified ore, and the three parts of qualified ore are combined.

[0067] After the above pre-s...

Embodiment 2

[0069] pair containing WO 3 0.245% wolframite raw ore is pre-selected and discarded, the steps are as follows:

[0070] (1) After crushing the wolframite raw ore to -80mm, carry out screening and classification pretreatment, and divide it into three grades of -80+12mm, -12+0.5mm and -0.5mm, of which -0.5mm grade products are directly used as Qualified mine;

[0071] (2) Use an intelligent ore sorting machine to pre-select and discard the -80+12mm grain grade products to obtain rough concentrates, crush the obtained rough concentrates to -12mm, and then screen and classify them into -12+0.5mm and -0.5mm; Among them, -0.5mm grain size products are directly regarded as qualified ore;

[0072] (3) The -12+0.5mm particle size product obtained in step (1) and step (2) is pre-selected and discarded by dense medium beneficiation equipment. 0.5mm, the obtained concentrate is regarded as qualified ore, and the three parts of qualified ore are combined.

[0073] After the above pre-s...

Embodiment 3

[0075] pair containing WO 3 0.212% wolframite raw ore is pre-selected and discarded, the steps are as follows:

[0076] (1) After crushing the wolframite raw ore to -80mm, carry out screening and classification pretreatment, and divide it into three grades of -80+12mm, -12+0.5mm and -0.5mm, of which -0.5mm grade products are directly used as Qualified mine;

[0077] (2) Use an intelligent ore sorting machine to pre-select and discard the -80+12mm grain grade products to obtain rough concentrates, crush the obtained rough concentrates to -12mm, and then screen and classify them into -12+0.5mm and -0.5mm; Among them, -0.5mm grain size products are directly regarded as qualified ore;

[0078] (3) The -12+0.5mm particle size product obtained in step (1) and step (2) is pre-selected and discarded by dense medium beneficiation equipment. 0.5mm, the obtained concentrate is regarded as qualified ore, and the three parts of qualified ore are combined.

[0079] After the above pre-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com