Preparation method of silicon dioxide/NaA molecular sieve composite membrane

A technology of silica and molecular sieves, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, membrane technology, etc., can solve problems such as polycrystalline membranes are easily damaged and affect membrane separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

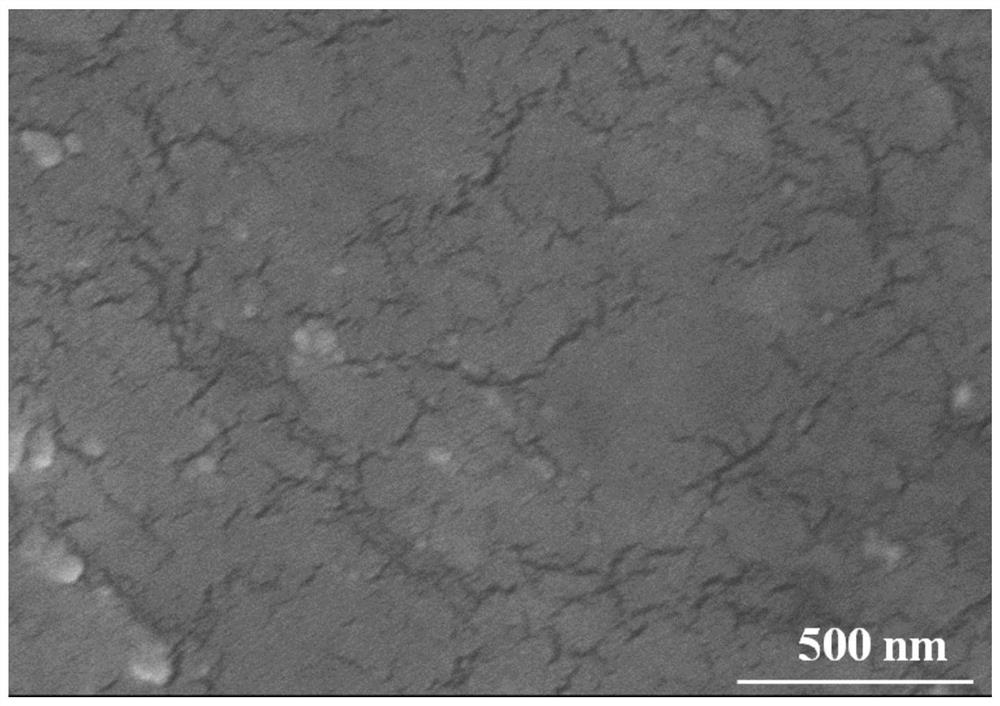

[0019] Add Tween-80 into water, stir evenly to prepare a Tween-80 aqueous solution with a concentration of 1%. At room temperature, the tubular NaA molecular sieve membrane was immersed in Tween-80 aqueous solution and stirred slowly. After soaking for 1 h, the tubular NaA molecular sieve membrane was taken out, washed once with ethanol and water, and dried in a vacuum oven. Dissolve ethyl orthosilicate in ethanol, then add deionized water and ammonia water in sequence (volume ratio of ethyl orthosilicate: water: ammonia water: ethanol is 1:1:1:20 respectively) to form a mixed solution. The dried tubular NaA molecular sieve membrane was immersed in the mixed solution of ethyl orthosilicate, slowly stirred for 6 hours, then taken out, and washed twice with ethanol. Then put it into a vacuum oven for drying to obtain a silica-modified NaA molecular sieve membrane. The surface morphology of the modified NaA molecular sieve membrane is as follows: figure 2 As shown, with the u...

Embodiment 2

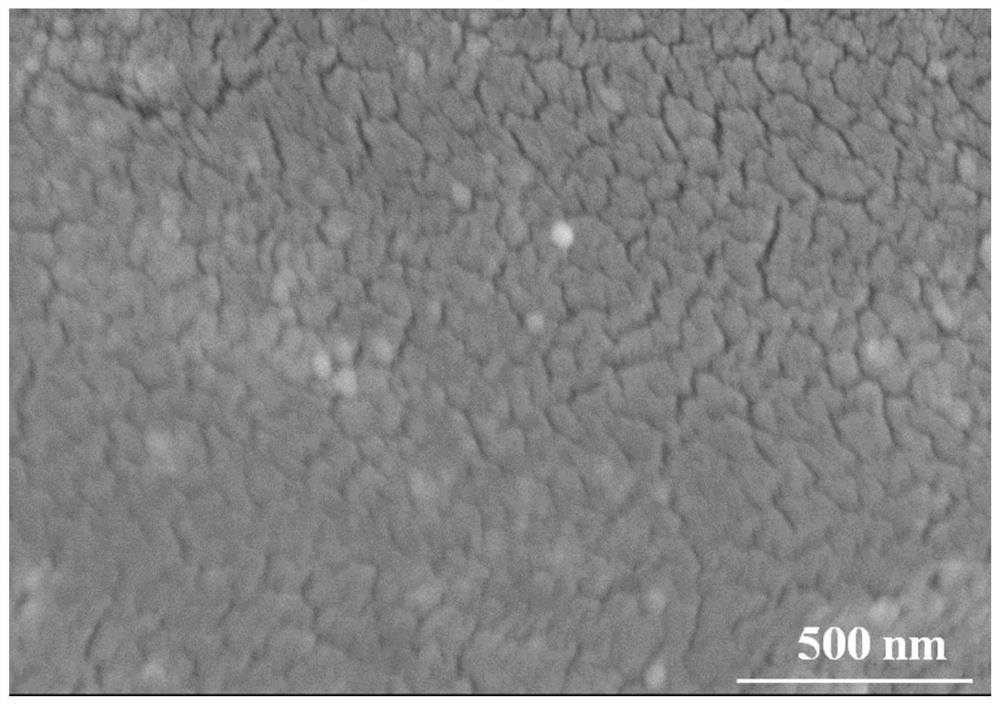

[0022] Add polyvinyl alcohol into water, stir evenly to prepare a 3% polyvinyl alcohol aqueous solution. At room temperature, the tubular NaA molecular sieve membrane was immersed in an aqueous solution of polyvinyl alcohol and stirred slowly. After soaking for 6 h, the tubular NaA molecular sieve membrane was taken out, washed once with ethanol and water, and dried in a vacuum oven. Dissolve ethyl orthosilicate in ethanol, then add deionized water and ammonia water in sequence (volume ratio of ethyl orthosilicate: water: ammonia water: ethanol is 1:3:3:50 respectively) to form a mixed solution. The dried tubular NaA molecular sieve membrane was immersed in the mixed solution of ethyl orthosilicate, slowly stirred for 12 hours, then taken out, and washed twice with ethanol. Then put it into a vacuum oven for drying to obtain a silica-modified NaA molecular sieve membrane. Test the separation performance of the modified NaA molecular sieve membrane: the operating temperature ...

Embodiment 3

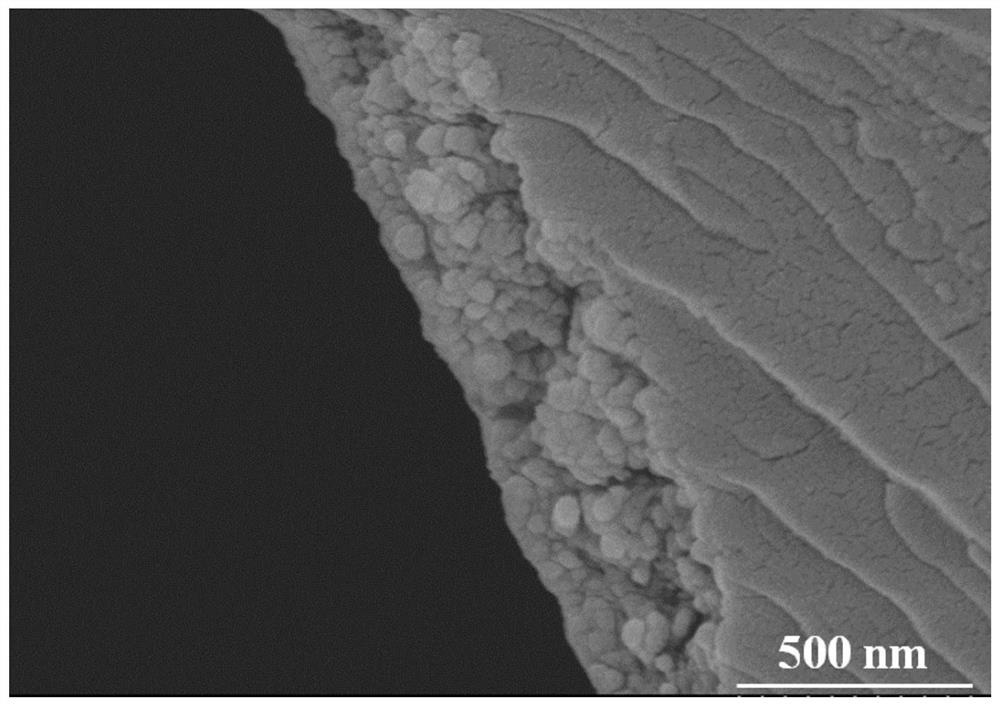

[0024] The chitosan is added into water, stirred evenly to prepare a chitosan aqueous solution with a concentration of 5%. At room temperature, the tubular NaA molecular sieve membrane was immersed in chitosan aqueous solution and stirred slowly. After soaking for 12 hours, the tubular NaA molecular sieve membrane was taken out, washed once with ethanol and water, and dried in a vacuum oven. Dissolve ethyl orthosilicate in ethanol, then add deionized water and ammonia water in sequence (volume ratio of ethyl orthosilicate: water: ammonia water: ethanol is 1:3:5:50 respectively) to form a mixed solution. The dried tubular NaA molecular sieve membrane was immersed in the mixed solution of ethyl orthosilicate, slowly stirred for 24 hours, then taken out, and washed twice with ethanol. Then put it into a vacuum oven for drying to obtain a silica-modified NaA molecular sieve membrane. Test the separation performance of the modified NaA molecular sieve membrane: the operating temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com