Electric-powered actuator and electric braking device

An actuator, electric technology, applied in the direction of braking transmission, motor generator control, transmission control, etc., can solve the problem that the vehicle cannot start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

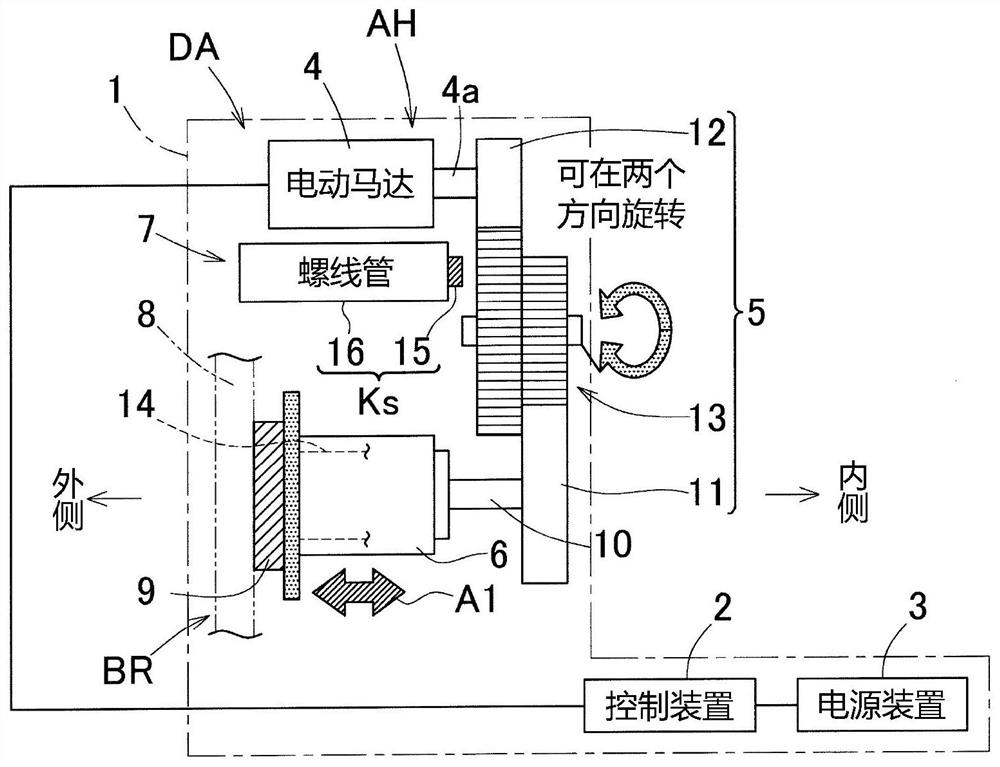

[0073] Combine Figures 1 to 14 The electric brake device having an electric actuator according to the embodiment of the present invention will be described. The electric brake device is mounted on a vehicle. like figure 1 As shown, the electric brake device 1 has an electric actuator DA and a friction brake BR. First, the structure of the electric actuator DA and the friction brake BR will be described.

[0074]

[0075] The electric actuator DA includes an actuator body AH, a power supply device 3, and a control device 2 described later. The actuator body AH has an electric motor 4, a linear moving mechanism 6, a speed reducer 5, a parking brake mechanism 7, an angle sensor SA ( Figure 4 ), Load sensor SB ( Figure 4 . like Figure 4 As shown, the brake actuator BA is composed of an actuator body AH and a friction brake BR.

[0076] like figure 1 with Figure 4 As shown, the electric motor 4 has a rotor and a stator, for example, by a synchronous motor of a permanent magnet. As the...

Embodiment approach

[0156] Next, another embodiment will be described other embodiments. In the following description, the same reference numerals corresponding to each of the items in the first embodiment described embodiments part, overlapping description is omitted. In the case where only a portion of the structure description, unless otherwise specified, the rest of the configuration is the same as the previously described embodiment. Serve the same effect by the same structure. Not only the combination of parts described in the embodiments specifically described, as long as no particular impediment to the combination, the embodiment may be partially combined with each other.

[0157]

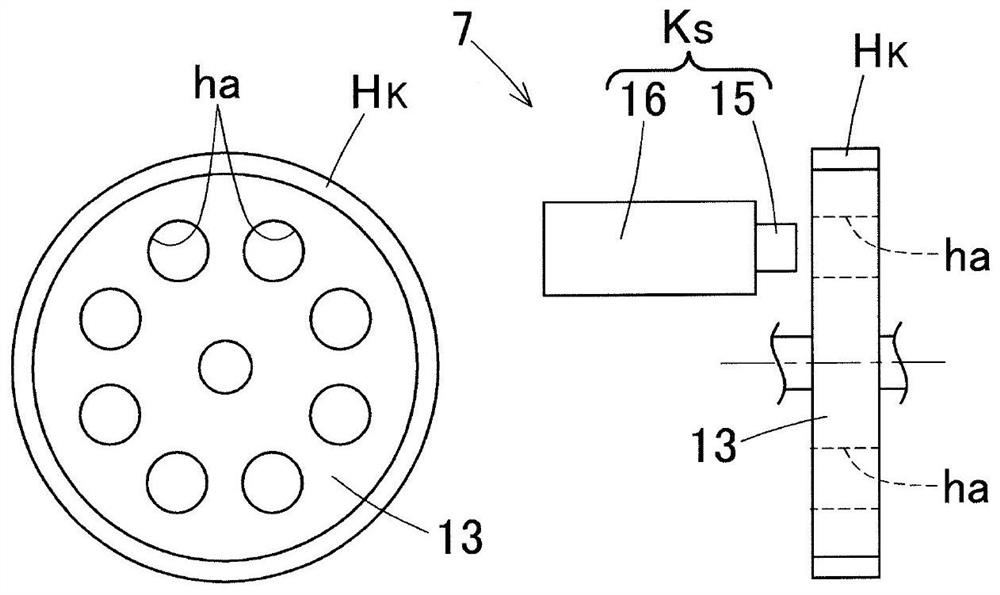

[0158] Figure 15A Further provided showing the rotation axis direction of the intermediate gear reducer 5 engaging member 13 rotate synchronously rotating shaft 32 (engaged portion), and an example of a radial groove provided on mz the engaging member 32. Mz the groove in any direction with respect to the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com