Method for detecting five chlorogenic acid substances in bilberry fruits through ultra-high performance liquid chromatography-tandem mass spectrometry

A technology of ultra-high performance liquid chromatography and detection method, which is applied in the field of detection of five chlorogenic acids in cranberry fruit by ultra-high performance liquid chromatography tandem mass spectrometry, which can solve the problem of less chlorogenic acids and achieve good repeatability , Good separation effect, efficient qualitative and quantitative detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

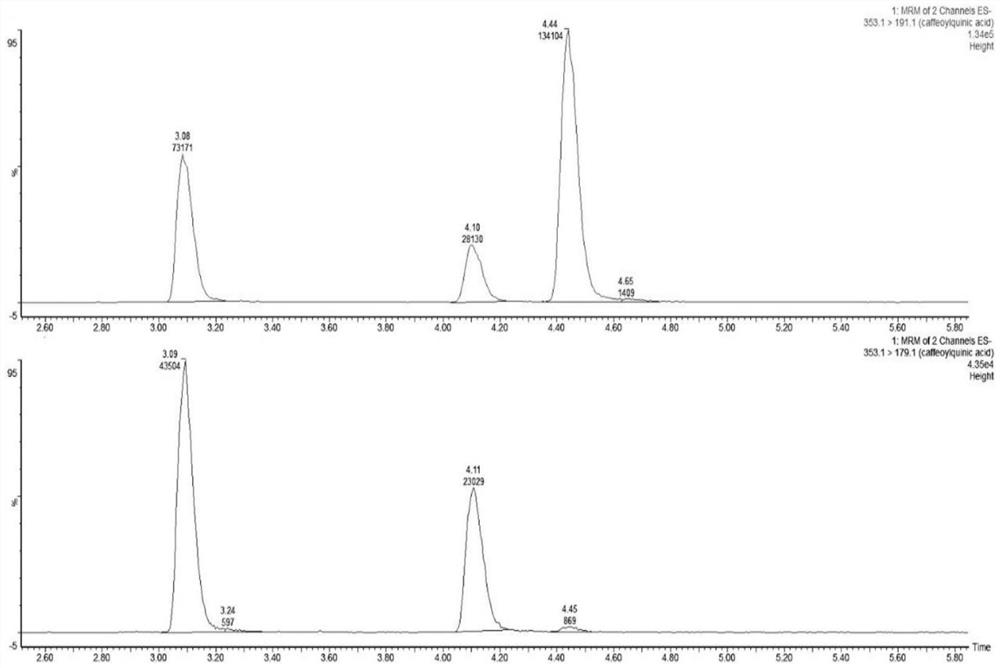

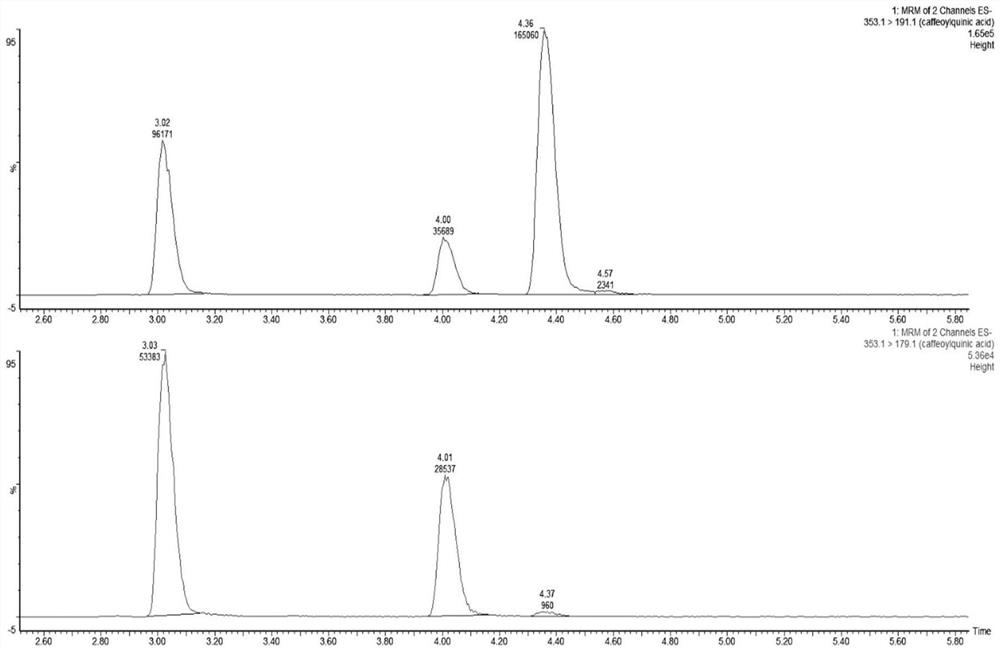

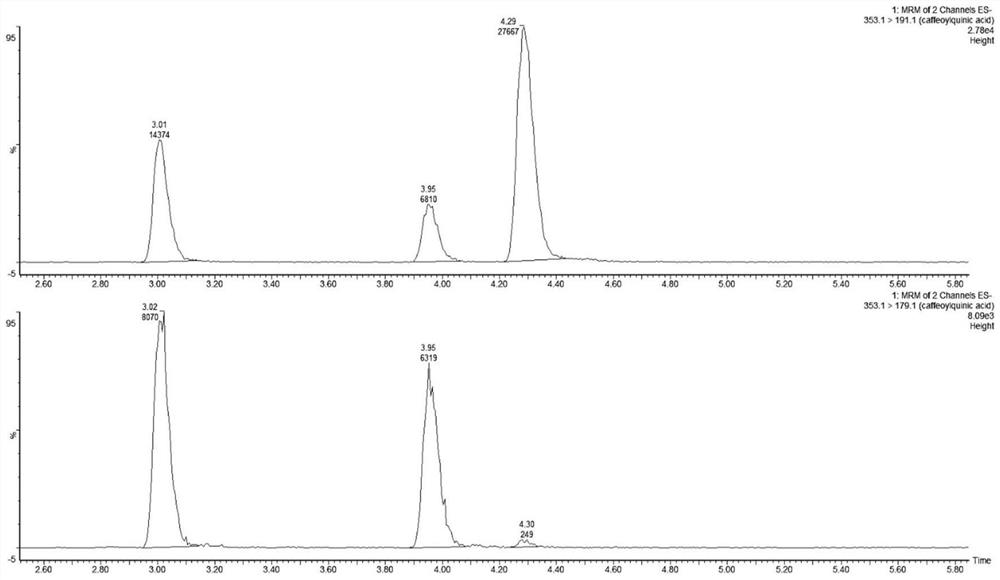

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for detecting chlorogenic acid, neochlorogenic acid, cryptochlorogenic acid, isochlorogenic acid A and isochlorogenic acid B in cranberry fruit by ultra-high performance liquid chromatography tandem mass spectrometry, specifically as follows:

[0046] 1. Extraction of five chlorogenic acids in lingonberry fruit

[0047] The lingonberry fruit was frozen and ground with liquid nitrogen, and 90% methanol was used as the extraction solvent. The mass volume ratio of the lingonberry fruit to the extraction solvent was 10g:50mL, and the ground fruit was subjected to ultrasonic extraction for 10 minutes.

[0048] 2. Purification of five chlorogenic acids

[0049] Centrifuge the extract obtained in the above step 1 in a centrifuge at 8000r / min for 10min, draw the sample in a 5mL centrifuge tube into a rotary evaporator, and evaporate the organic phase on a rotary evaporator at 40°C. Take the HLB solid-phase extraction column, first add 5mL of m...

Embodiment 2

[0054] This embodiment provides a method for detecting chlorogenic acid, neochlorogenic acid, cryptochlorogenic acid, isochlorogenic acid A and isochlorogenic acid B in cranberry fruit by ultra-high performance liquid chromatography tandem mass spectrometry, specifically as follows:

[0055] 1. Extraction of five chlorogenic acids in lingonberry fruit

[0056] The lingonberry fruit was frozen and ground with liquid nitrogen, and 100% methanol was used as the extraction solvent. The mass volume ratio of the lingonberry fruit to the extraction solvent was 2g:10mL, and the ground fruit was subjected to ultrasonic extraction for 20 minutes.

[0057] 2. Purification of five chlorogenic acids

[0058] Centrifuge the extract obtained in the above step 1 in a centrifuge at 8000r / min for 10min, draw the sample in a 5mL centrifuge tube into a rotary evaporator, and evaporate the organic phase on a rotary evaporator at 40°C. Take the HLB solid-phase extraction column, first add 5mL of m...

Embodiment 3

[0063] In this embodiment, the experimental results of the partial optimization process of the detection method provided in Examples 1 and 2 are listed as follows:

[0064] 1. Optimization of the extraction method

[0065]Weigh 10 g of lingonberry fruit after different pretreatments (after liquid nitrogen freezing and grinding, after homogenization, after liquid nitrogen freezing and grinding for one week and after homogenization for one week) into beakers, and add different concentrations of solvents (30 % Methanol, 50% Methanol, 70% Methanol, 90% Methanol, 100% Methanol, 30% Ethanol, 50% Ethanol, 70% Ethanol, 90% Ethanol, 100% Ethanol and ultrapure water) after dissolving to a capacity of 50mL In the bottle, use different extraction methods (ultrasonic extraction method or vibration extraction method) to extract for a certain period of time (10min, 20min and 30min), centrifuge in a centrifuge at 8000r / min for 10min, filter through a 0.22μm organic phase filter membrane, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com