Method for determining content of metal elements in polyvinylidene fluoride resin

A polyvinylidene fluoride resin and metal element content technology, which is applied in the field of fluoropolymer analysis and detection, can solve the problems of inability to eliminate organic interference, affect the accuracy of analysis results, high cost and maintenance costs, and achieve instrument cost and maintenance costs Low, stable and reliable results, low detection limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of PVDF resin sample solution: Accurately weigh 2.0058g sample, add 20mL THF, then add 80mL NMP, heat and stir on a metal bath at 60°C for 120min until the sample dissolves, and obtain a PVDF resin sample solution. The used solvent THF:NMP=1:4 (volume ratio) was used as a blank.

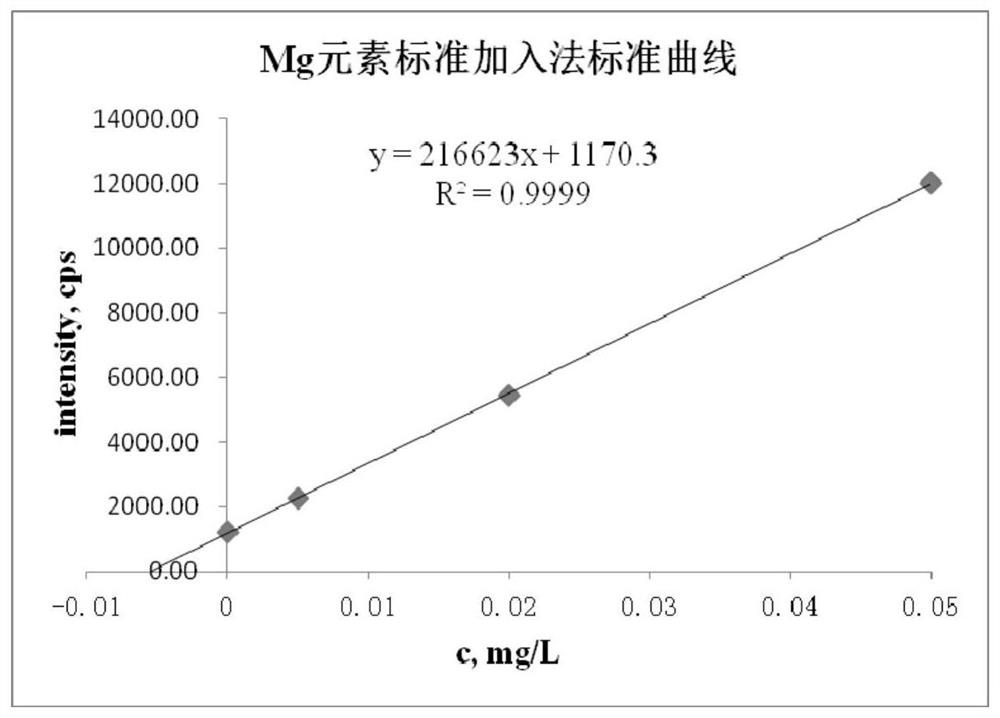

[0037] (2) Preparation of standard addition method standard solution: respectively pipette 5 equal parts of 10.0mL PVDF resin sample solution prepared in the above step (1) into a 25mL volumetric flask, from the prepared 1.0mg / mL K, Mg, Al, Pipette 0.0mL, 0.1mL, 0.2mL, 0.5mL, 1.0mL from the mixed standard solution of Cd, Cr, Fe, Cu, Ni, Mn, Pb, Na, Ca into the sample solution in sequence, and use THF:NMP=1: 4 (volume ratio) of mixed solvents to constant volume, to prepare series concentration standard addition method standard solutions.

[0038] (3) Set the ICP-OES instrument parameters: turn on the ICP-OES instrument to preheat, and perform optical initialization after the pr...

Embodiment 2

[0048] (1) Preparation of PVDF resin sample solution: Accurately weigh 3.0820g sample, add 500mL DMF, heat and stir on a metal bath at 80°C for 60min until the sample dissolves, and obtain a PVDF resin sample solution. The used solvent DMF was used as a blank.

[0049] (2) Preparation of standard addition method standard solution: respectively pipette 5 equal parts of 50.0mL PVDF resin sample solution prepared in the above step (1) into a 100mL volumetric flask, from the prepared 1.0mg / mL K, Mg, Al, Pipette 0.0mL, 1.0mL, 2.0mL, 5.0mL, and 10.0mL from the mixed standard solution of Cd, Cr, Fe, Cu, Ni, Mn, Pb, Na, and Ca into the PVDF resin sample solution, and dilute to volume with solvent DMF , to prepare a series of concentration standard addition method standard solutions.

[0050] (3) Set the ICP-OES instrument parameters: turn on the ICP-OES instrument to preheat, and perform optical initialization after the prism temperature is stable, and set the instrument parameters: ...

Embodiment 3

[0057] (1) Preparation of PVDF resin sample solution: Accurately weigh 0.1009g sample, add 40mL DMF and 10mL TEP, heat and stir on a metal bath at 90°C for 40min until the sample dissolves, and obtain a PVDF resin sample solution. The used solvent DMF:TEP=4:1 (volume ratio) was used as a blank.

[0058] (2) Preparation of standard addition method standard solution: pipette 4 equal parts of 10.0mL PVDF resin sample solution prepared in the above step (1) into a 25mL volumetric flask, and prepare 1.0mg / mL of K, Mg, Al, Pipette 0.0mL, 0.05mL, 0.2mL, and 0.5mL from the mixed standard solution of Cd, Cr, Fe, Cu, Ni, Mn, Pb, Na, and Ca into the PVDF resin sample solution in sequence, and use DMF:TEP=4:1 (volume ratio) of the mixed solvent to constant volume to prepare a series of concentration standard addition method standard solutions.

[0059] (3) Set the ICP-OES instrument parameters: turn on the ICP-OES instrument to preheat, and perform optical initialization after the prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com