A transition function hydraulic valve

A hydraulic valve and functional technology, which is applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problem of large impact on the working oil port, achieve smooth movement, ensure positional accuracy, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

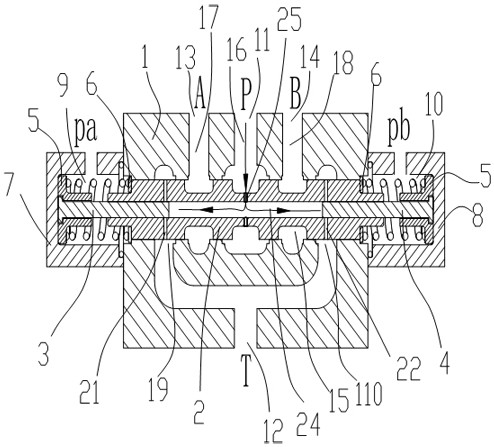

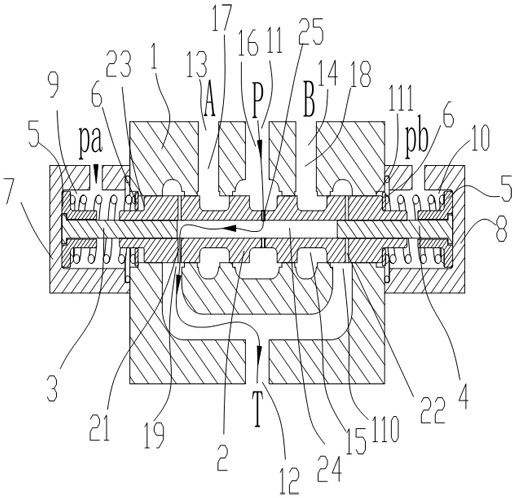

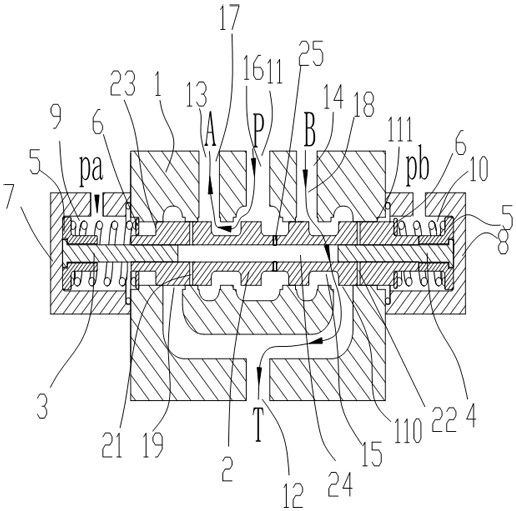

[0043] Such as Figure 1~4 , the transition function hydraulic valve in this embodiment includes a valve body 1 and a valve core 2, wherein the valve body 1 is provided with a pressure oil port 11, an oil return port and at least one working oil port, and the valve core 2 is slidably fitted on the valve body 1 Inside, the spool 2 slides to control the on-off between the pressure oil port 11, the working oil port and the oil return port.

[0044] In order to release the pressure before the connection between the pressure oil port 11 and the working oil port, the spool 2 of this embodiment is equipped with a pressure relief oil circuit. According to an embodiment of the present invention, the pressure relief oil circuit includes The oil passage 24 in the inner core and the oil inlet hole 25 and the oil discharge hole arranged on the valve core 2, the oil inlet hole 25 and the oil discharge hole are respectively connected with the oil passage 24 in the core. When the valve core 2...

Embodiment 2

[0061] Such as figure 1 As shown, the valve body 1 of this embodiment is provided with a spool hole 15, and the valve body 1 is provided with a pressure oil passage 16 communicating with the pressure oil port 11 and a working oil passage communicating with the working oil port. There are two working oil ports, and the two working oil ports are arranged on both sides of the pressure oil port 11. The oil inlet hole 25 is set corresponding to the pressure oil port 11. There are two groups of oil discharge holes, which are symmetrically arranged on the sides of the oil inlet hole 25. On both sides, there are two sets of end caps and on-off structures, which are respectively arranged at both ends of the valve body 1, and the two sets of on-off structures correspond to two sets of oil discharge holes.

[0062] Specifically, the two working oil ports are respectively the first working oil port 13 (A in the figure) and the second working oil port 14 (B in the figure), and the two end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com