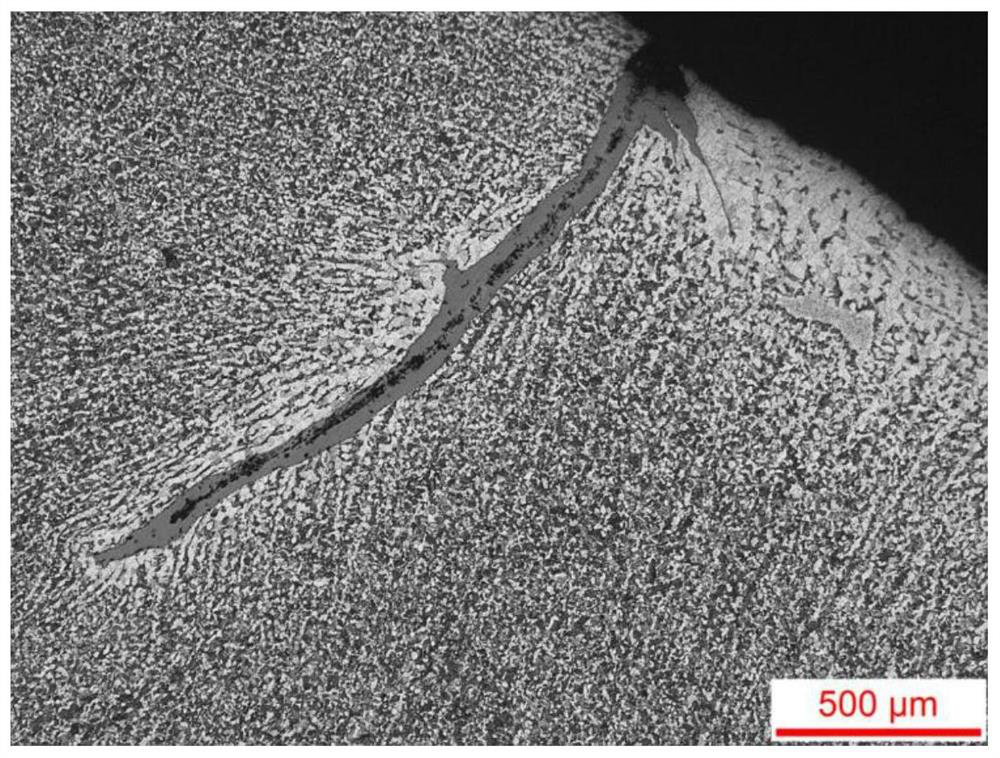

A kind of medium carbon non-quenched and tempered steel and preparation method thereof

A technology of non-quenched and tempered steel and molten steel, applied in metal rolling, temperature control, etc., can solve problems such as surface cracking, achieve the effects of reducing internal stress, avoiding brittle cracking, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a medium carbon non-quenched and tempered steel, which is mainly prepared through the following steps:

[0048] The composition of medium carbon non-quenched and tempered steel includes: C 0.37%, Si 0.32%, Mn 1.24%, P 0.010%, S0.004%, Cr 0.12%, Ti 0.003%, Nb 0.002%, V 0.09%, Al 0.014 %, Ni 0.001%, N0.0134%, the balance is Fe and inevitable impurities, and Σ(Al+Nb+V+Ti) / N is 8.1.

[0049] The molten steel prepared from the above components is sequentially subjected to converter smelting, LF furnace refining, continuous casting and rolling. The size of the continuous casting billet is controlled to be 280mm×280mm, the specific water volume of the secondary cold water in the continuous casting production is 0.27L / kg, the temperature of the continuous casting billet entering the pit is 772-831°C, the cooling time in the pit is 106h, the pit temperature is 145°C, and the rolling The casting billet is heated before production. The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com