Vacuum electroslag furnace with electrode rotation and vibration functions

An electroslag furnace and electrode technology, which is applied in the field of metallurgical equipment, can solve the problems of little contribution to the inner quality of the steel ingot, short circuit current, poor rigidity of the column, etc., and achieve the effect of increasing the residence time and running trajectory, and enhancing the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

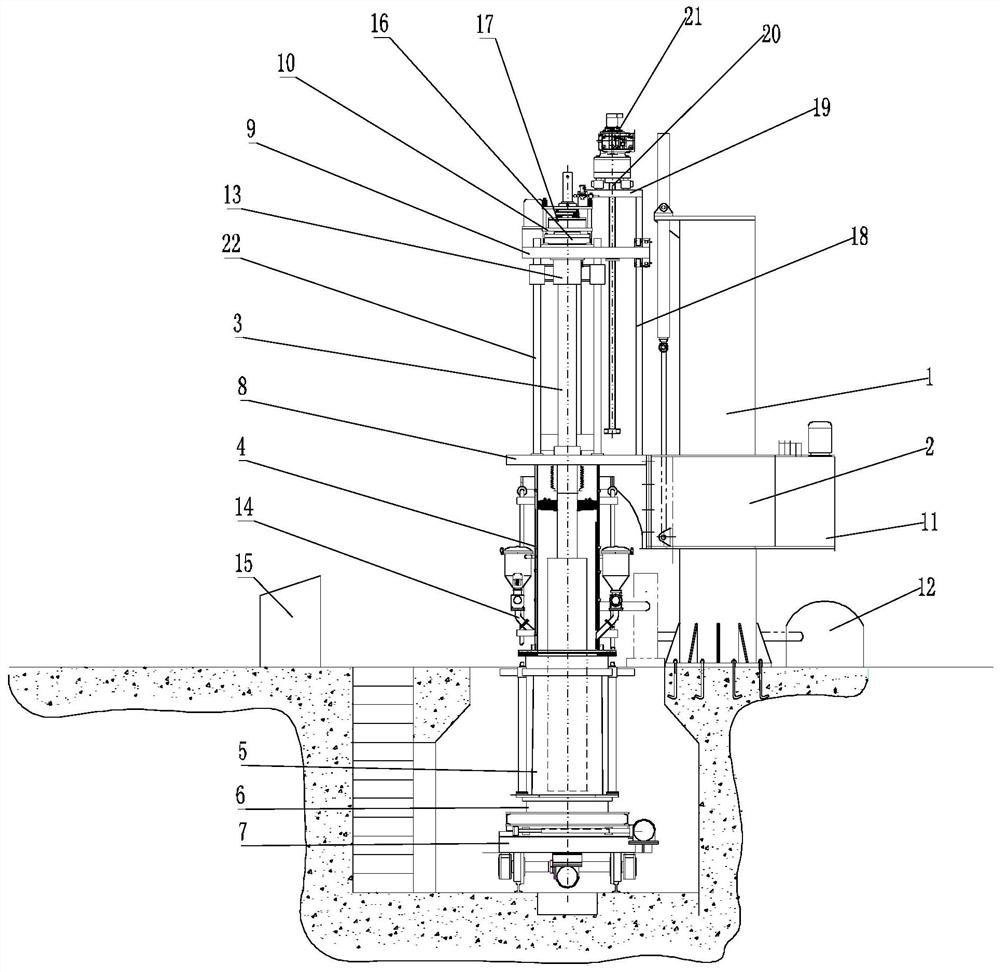

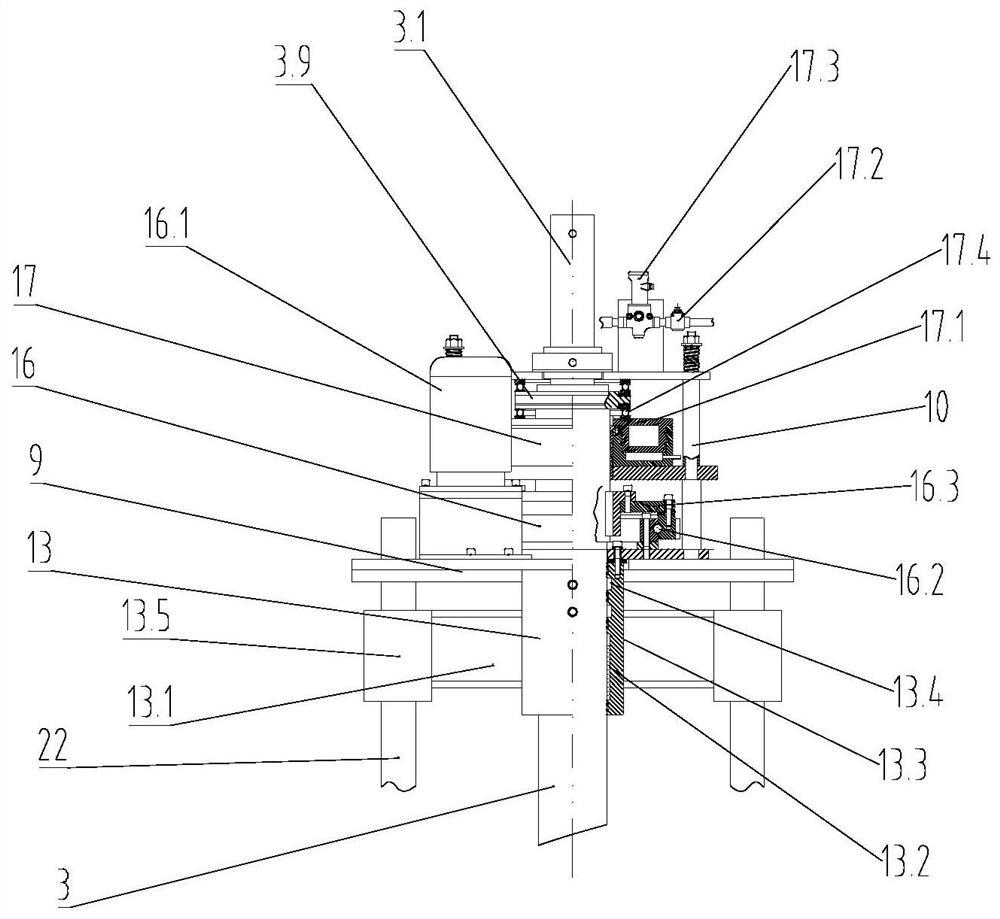

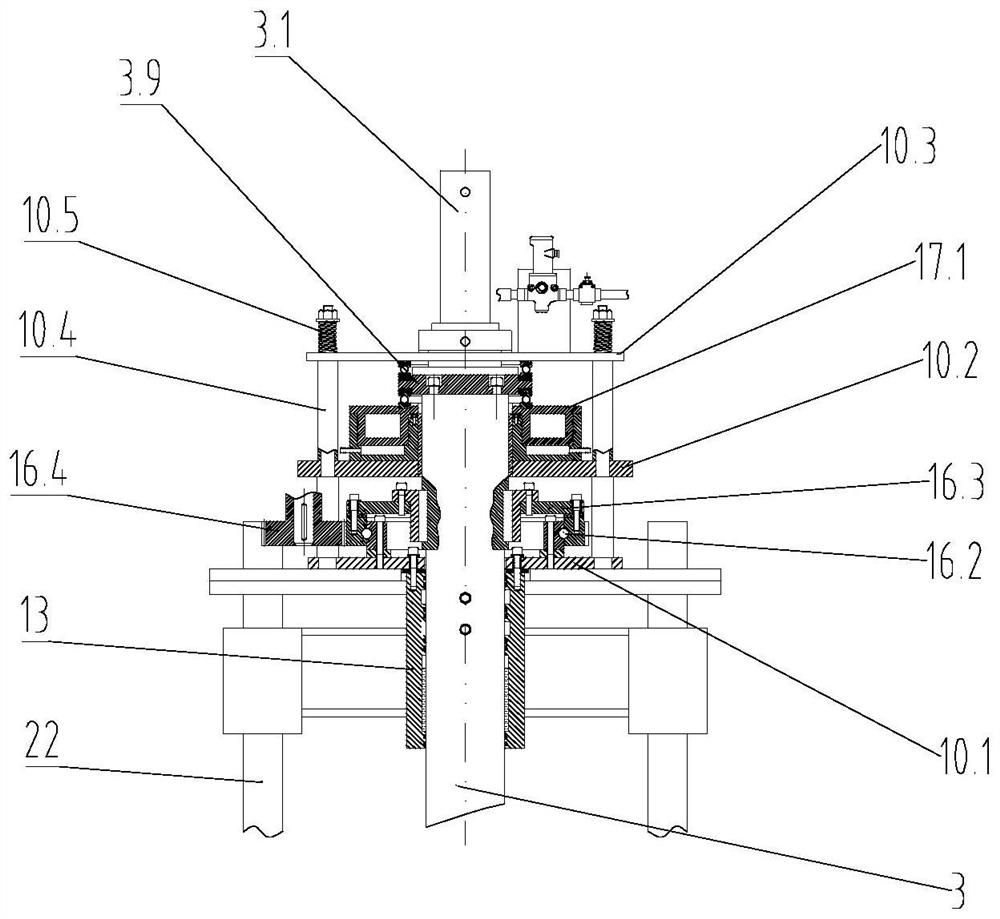

[0035] Such as Figure 1~4As shown, a vacuum electroslag furnace with electrode rotation and vibration functions. The electroslag is in a tower structure, including a cross-arm column 1, a cross arm 2, a conductive material rod 3, a closed atmosphere protective cover 4, and a closed crystallizer. 5. Bottom water tank 6 and platform truck 7. The cross arm is installed on the column, and the cross arm platform 8 on one side of the cross arm is provided with a conductive rod platform 9 and a lifting mechanism for the conductive rod platform. A conductive material rod 3 holding an electrode 3.8 is installed on the material rod platform 9, and the conductive material rod can move up and down through the cross arm platform 8 under the action of the conductive material rod platform lifting mechanism. There is an electrode rotation mechanism 16 and an electrode vibration mechanism 17; the upper end of the atmosphere protection cover 4 is fixedly connected with the cross-arm platform 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com