Annealing device for wire and cable manufacturing

An annealing device, wire and cable technology, applied in the field of wire and cable, can solve the problems of incomplete annealing of wire and cable, affecting the use effect of wire and cable, unable to guarantee wire and cable, etc., to reduce cable breakage, avoid excessive deviation, and facilitate observation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

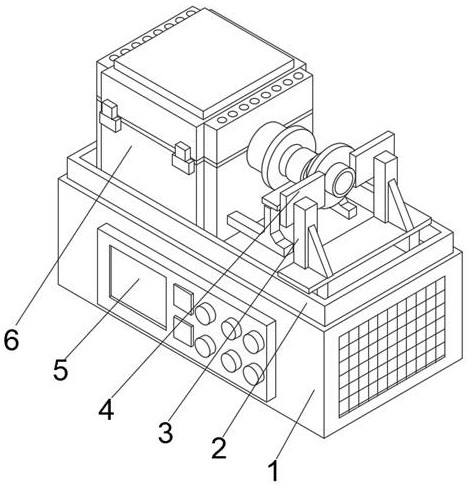

[0040] see Figure 1-6 , the present invention provides a technical solution: an annealing device for wire and cable manufacturing, including a device body 1, a control panel 5 is fixedly connected to the middle position of the front bottom of the device body 1, and a control panel 5 is fixedly connected to the middle position of the top left side of the device body 1. There is an annealing device 6, the top of the equipment main body 1 is located on both sides of the annealing device 6 and is fixedly connected with a protection bracket 2, and the top right side of the protection bracket 2 is fixedly connected with a fixing frame 3, and the side of the fixing frame 3 close to the annealing device 6 is fixedly connected There is feed guide sleeve 4.

[0041] Wherein, the annealing device 6 includes an opening and closing annealing box 63, the bottom of the right side outer wall of the opening and closing annealing box 63 is fixedly connected with a guide frame 61, and the middl...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an annealing device for wire and cable manufacturing, step 1: install the equipment, and connect the fixing frame 3 with the protective bracket 2 , as the feed guide sleeve 4 is connected with the protective bracket, the feeding position of the feed guide sleeve 4 and the collecting position of the annealing device 6 are kept horizontal;

[0048] Step 2: guide the wires and cables through the guide cavity produced by the guide frame 61 and the feed adjustment body 62, adjust the tension angle during transportation, and use the heat preservation mechanism 64 and the heating mechanism 65 to keep the internal temperature constant;

[0049] Step 3: Connect the heat preservation base 642 with the protection mechanism 645, and connect the anti-scalding shell 643 with the protection mechanism 645, so that it can be adjusted with the opening and closing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com