Antibacterial enhanced low-temperature-resistant slow-rebound polyurethane sponge and preparation method thereof

A technology of polyurethane sponge and slow rebound polyether, which is applied in the field of organic polymer synthesis, can solve the problems of high toxicity, infection of human body, and pollution of products, etc., and achieve the effect of enhanced low temperature resistance, enhanced antibacterial effect, and not easy to damage and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Antibacterial enhancer Alc-S-GO + Preparation of:

[0048] First, 5 mL of 85 wt% phosphoric acid aqueous solution was added to a 100 mL round bottom flask in an ice-water bath, and then 45 mL of 95 wt% concentrated sulfuric acid was poured into it. After magnetic stirring at 4 °C for 10 min, 1 g of flake graphite (per 3 Add 0.1 g within 30 minutes), and continue to stir for 10 minutes after the addition. Then slowly add 7 g of potassium permanganate (1 g every 10 min, complete within 70 min), continue to react for 20 min after the addition is complete, move the system to a water bath at 50°C, stir magnetically for 10 h, and wash Freeze-dried to get GO;

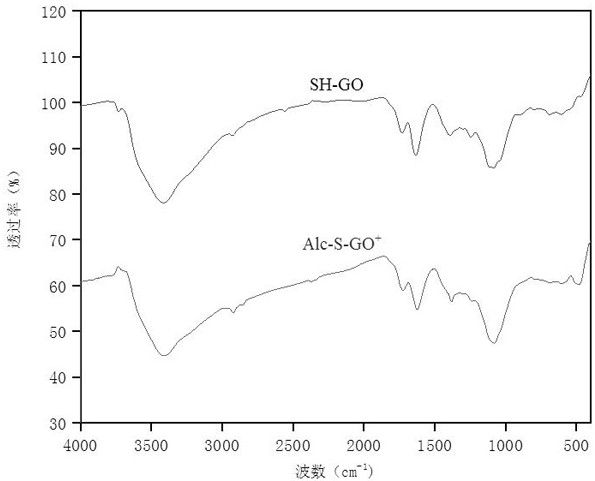

[0049] Preparation of SH-GO: 0.2 g GO was added to a 50 mL round bottom flask filled with 20 mL of absolute ethanol, and ultrasonicated at 100 W for 1 h in an ultrasonic cleaner. Then, 2 mL of (3-mercaptopropyl)trimethoxysilane (KH-590) was added to the GO dispersion, and stirred for 24 h at room temperature unde...

Embodiment 2

[0061] (1) Antibacterial enhancer Alc-S-GO + The preparation: with embodiment 1,

[0062] (2) Preparation of low temperature resistant agent KH-151 grafted polyether modified silicone oil: same as Example 1,

[0063] (3) Preparation of antibacterial enhanced low temperature resistant slow rebound polyurethane sponge:

[0064] Weigh the following raw materials in parts by weight: DALTOPED ® AQUAPUR 40 parts, PPG3000 40 parts, POP-2045 20 parts, Alc-S-GO + 10 parts, KH-151 grafted polyether modified silicone oil 5 parts, A33 1.2 parts, T9 0.4 parts, L580 1 part, deionized water 1.3 parts, MDI 62 parts;

[0065] will DALTOPED ® Add AQUAPUR, PPG3000, and POP-2045 into PP plastic cups in proportion, and then add Alc-S-GO in sequence according to the formula + , KH-151 grafted polyether modified silicone oil, A33, T9, L580, deionized water, stirred for 60 seconds under a mixer with a rotation speed of 1200 r / min, and recorded as component A;

[0066] Add 62 parts of MDI into ...

Embodiment 3

[0069] (1) Antibacterial enhancer Alc-S-GO + The preparation: with embodiment 1,

[0070] (2) Preparation of low temperature resistant agent KH-151 grafted polyether modified silicone oil: same as Example 1,

[0071] (3) Preparation of antibacterial enhanced low temperature resistant slow rebound polyurethane sponge:

[0072] Weigh the following raw materials in parts by weight: DALTOPED ® AQUAPUR 40 parts, PPG3000 40 parts, POP-2045 20 parts, Alc-S-GO + 5 parts, KH-151 grafted polyether modified silicone oil 10 parts, A33 1.2 parts, T9 0.4 parts, L580 1 part, deionized water 1.3 parts, MDI 62 parts;

[0073] will DALTOPED ®Add AQUAPUR, PPG3000, and POP-2045 into PP plastic cups in proportion, and then add Alc-S-GO in sequence according to the formula + , KH-151 grafted polyether modified silicone oil, A33, T9, L580, deionized water, stirred for 60 seconds under a mixer with a rotation speed of 1200 r / min, and recorded as component A;

[0074] Add 62 parts of MDI into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com