Preparation method of high-purity small-particle-size pranlukast

A small particle size, high purity technology, applied in organic chemistry and other directions, can solve the problems of poor solvent heating and reflux, difficult to meet particle size requirements, poor purification effect, etc., and achieve the effect of crystallization process block, easy pulverization, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

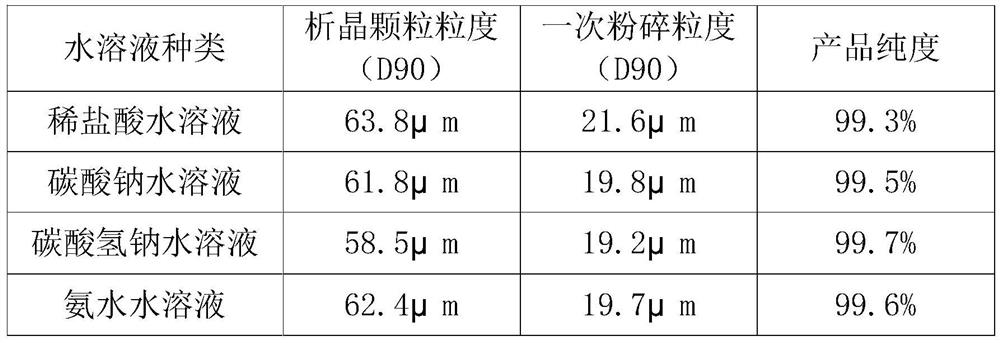

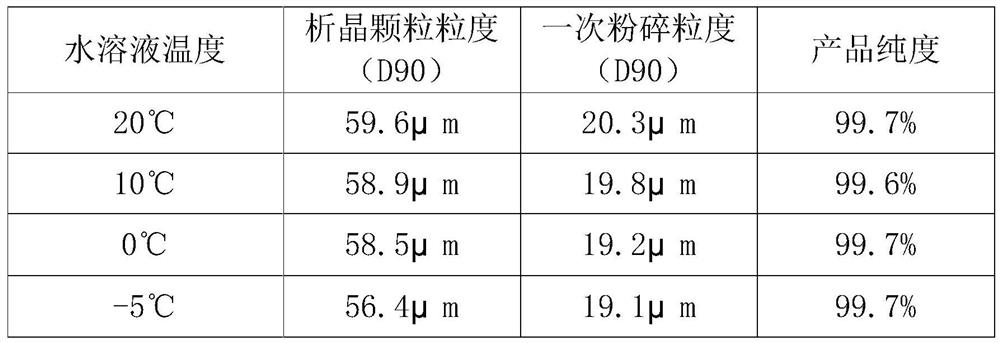

[0022] Example 1: In the mixed solvent of 400g ethyl acetate and 600g dimethylformamide, add 400g of pranlukast crude product (purity 95.4%), start stirring, heat up to slight reflux, after completely dissolving, in stirring state , the above solution was added to 1000mL aqueous sodium bicarbonate solution (concentration 10% m / m) at 0°C, a solid was precipitated under rapid stirring, filtered, the filter cake was washed with purified water, and the solid was vacuum-dried. The particle size distribution D90 is 58.5 μm, and the product purity is 99.6%.

[0023] The above-mentioned pranlukast refined product was pulverized once by jet, and the particle size distribution D90 of the obtained solid powder was 19.2 μm.

Embodiment 2

[0024] Embodiment 2: In the mixed solvent of 100g dichloromethane, 300g ethyl acetate and 600g dimethylformamide, add 400g pranlukast crude product (purity 95.4%), start stirring, heat up to slight reflux, until completely dissolved Finally, under stirring, the above solution was added to 1000ml aqueous sodium bicarbonate solution (concentration 15% m / m) at 0°C, solid was precipitated under rapid stirring, filtered, the filter cake was washed with purified water, and the solid was dried in vacuo. The particle size distribution D90 is 54.3 μm, and the product purity is 99.7%.

[0025] The above-mentioned pranlukast refined product was pulverized once by airflow, and the particle size distribution D90 of the obtained solid powder was 18.1 μm.

Embodiment 3

[0026] Example 3: In the mixed solvent of 300g ethyl acetate and 700g dimethylformamide, add 400g pranlukast crude product (purity 95.4%), start stirring, heat up to slight reflux, after completely dissolving, in stirring state Next, the above solution was added to 1000mL aqueous sodium bicarbonate solution (concentration 10% m / m) at 5°C, solids were precipitated under rapid stirring, filtered, the filter cake was washed with purified water, and the solids were vacuum-dried. The particle size distribution D90 is 57.6 μm, and the product purity is 99.5%.

[0027] The above-mentioned pranlukast refined product was pulverized once by jet, and the particle size distribution D90 of the obtained solid powder was 19.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com