Intelligent clamp for thin-wall cylindrical pipe fitting

A thin-walled cylinder and pipe fitting technology, which is applied in the field of intelligent fixtures for thin-walled cylindrical pipe fittings, achieves the effects of convenient and accurate pressure adjustment, preventing the clamping force from being too large or too small, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

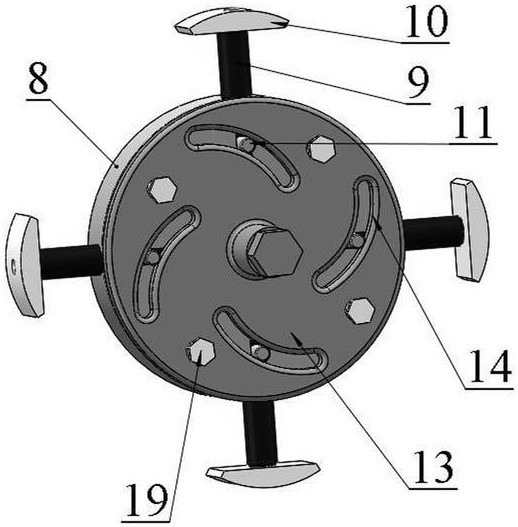

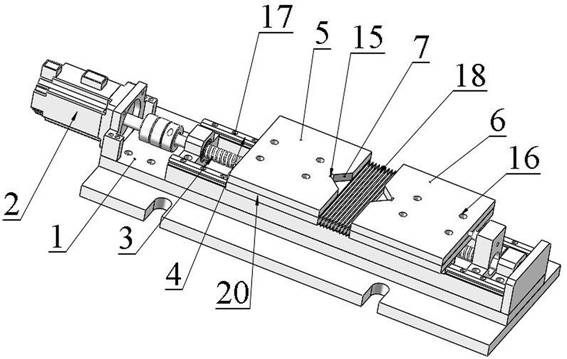

[0027] The following is attached Figure 1-7 The specific implementation manners of the present invention are further described in detail.

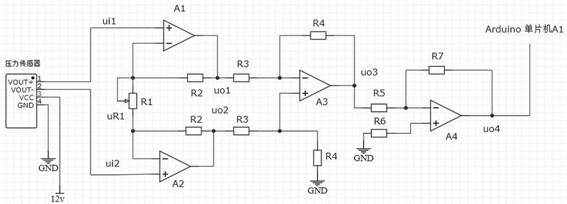

[0028] When this embodiment is in use, before starting, each part of the clamping table 1 is energized and checked whether there is a fault. If there is no fault, it can be used. The motor of the ball screw 3 is energized, and the ball screw 3 motor starts to rotate and drives the left transport platform 5 to the left to the initial position, and then adjusts the position of the right transport platform 6 so that the right end surface of the right transport platform 6 is in contact with the pressure sensor. Check whether the pressure sensor, the voltage amplifying circuit and the single-chip microcomputer are normal, and then manually adjust the distance between the right transport platform 6 and the pressure sensor, so that the pressure sensor and the right end surface of the right transport platform 6 are close to each other. After adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com