Organic garbage absorption tank of biological kitchen garbage machine

A technology for organic waste and kitchen waste, which is applied in the field of organic waste disposal tanks, can solve the problems of inconvenient humidity and temperature adjustment, structural restrictions, and the inconvenience of decomposing organisms to generate and use, so as to improve the convenience of use, quickly eliminate, and avoid disinfection. Effects of slower sodium response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

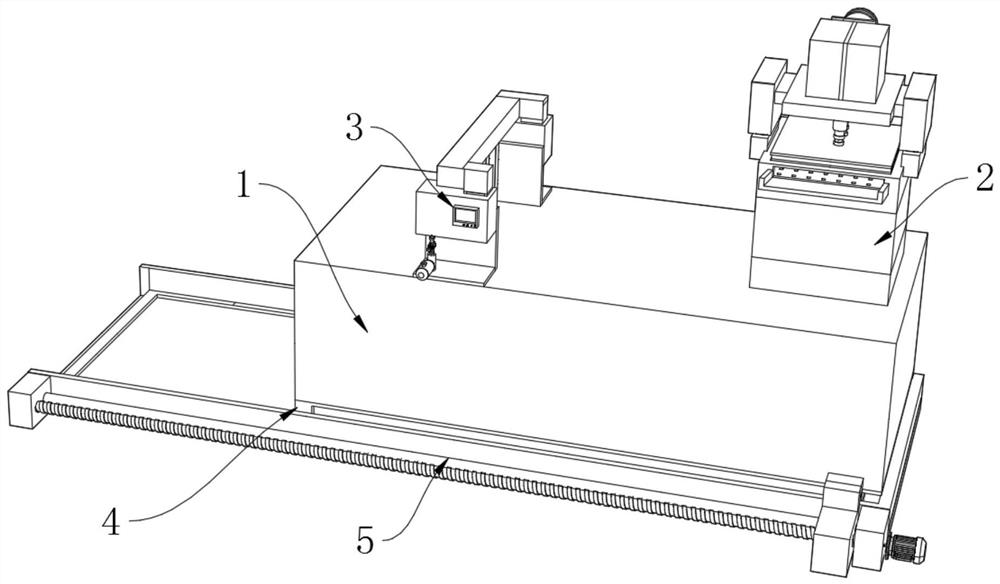

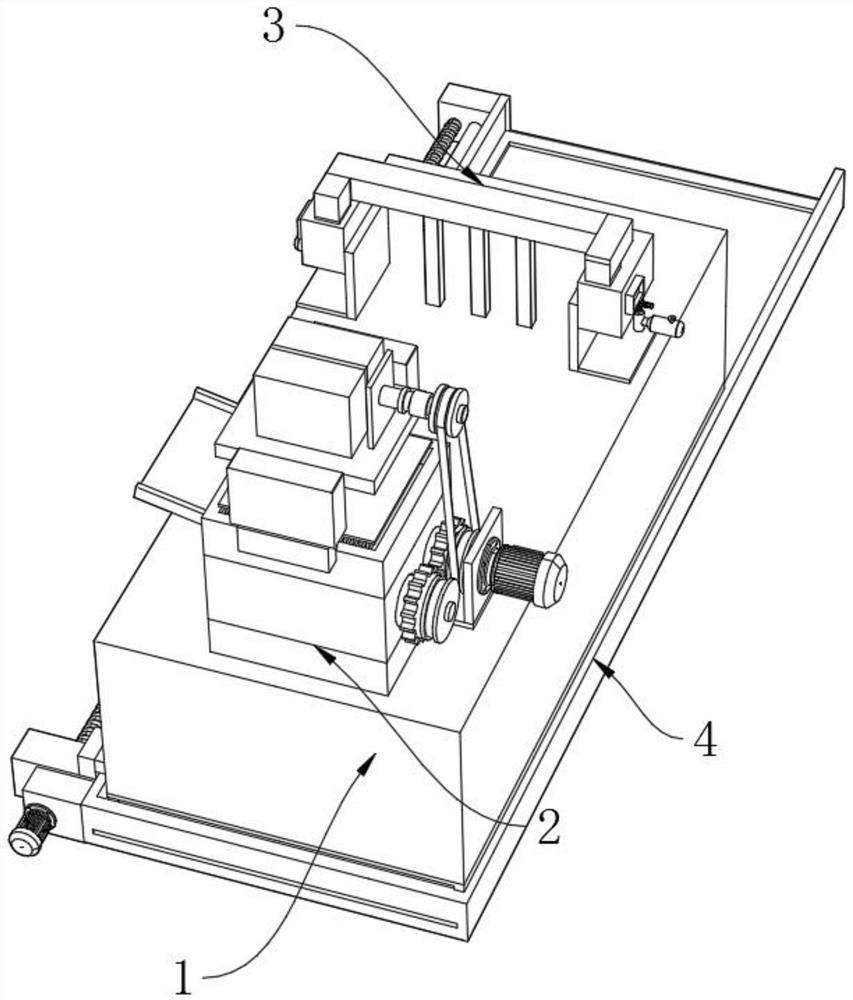

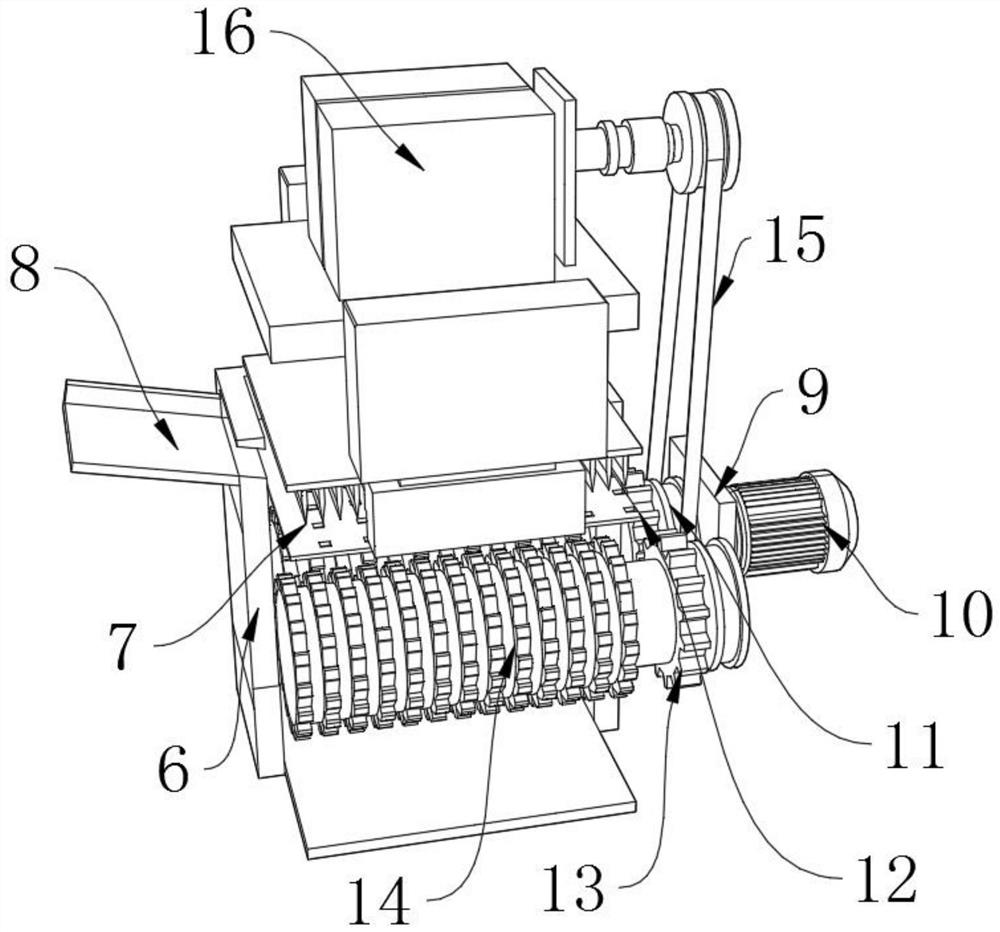

[0028] see Figure 1-8 , an organic waste storage tank of a biological kitchen waste machine.

[0029] Including the absorption reaction tank 1, the bottom end of the absorption reaction tank 1 is fixedly connected with the auxiliary guide derivation frame 4, the bottom end of the auxiliary guide derivation frame 4 is welded with an automatic derivation garbage structure 5, and the side of the top end of the absorption reaction tank 1 The biological cultivation humidity output structure 3 is fixedly connected, and the other side of the top of the absorption reaction tank 1 is fixedly connected with a multi-section matching pretreatment structure 2;

[0030] see Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com