Carbon/anthraquinone composite material, preparation method thereof and application of carbon/anthraquinone composite material in hydrogen peroxide synthesis

A technology of composite materials and carbon materials, which is applied in the field of carbon/anthraquinone composite materials and their preparation, can solve the problem of low product selectivity, achieve simple operation, meet a large number of needs, and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

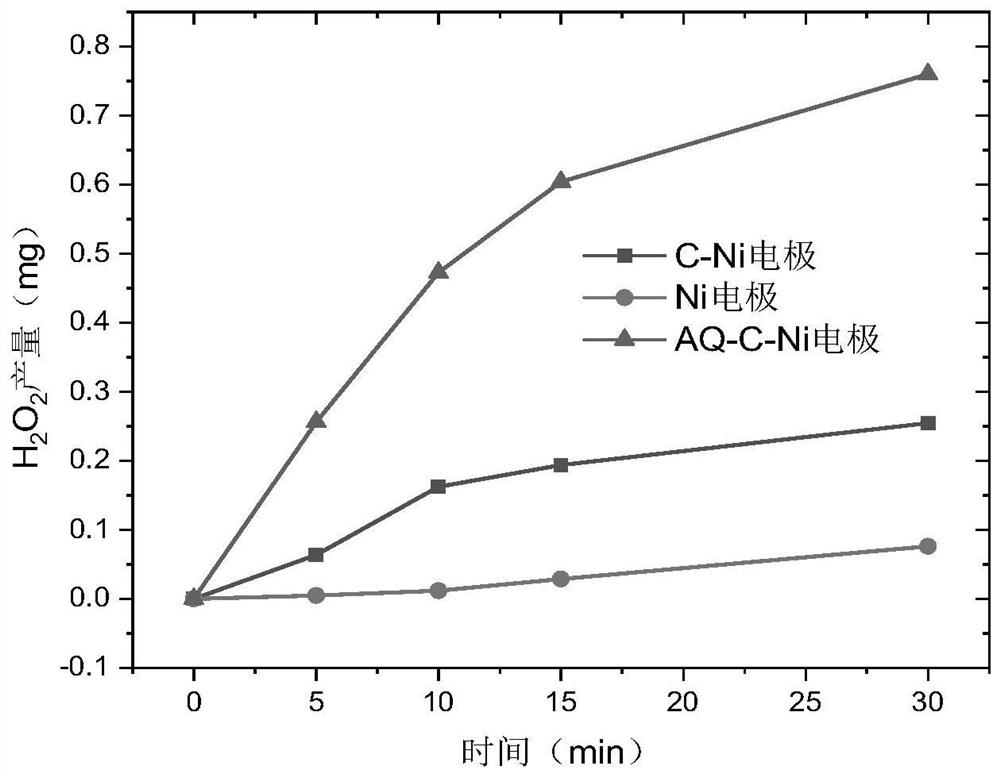

[0041] In this embodiment, carbon (C) and anthraquinone (AQ) composite materials are prepared, and they are loaded on a nickel foam conductive substrate to construct a carbon / anthraquinone composite electrode (AQ-C-Ni electrode), including the following steps:

[0042] (1): Conductive carbon black is selected as the carbon material, and 200 mg of conductive carbon black is weighed, washed with distilled water, and treated with plasma modification. Use self-assembly method to fix 2-aminoanthraquinone on conductive carbon black, dissolve 100mg of 2-aminoanthraquinone in 150mL acetonitrile, add 200mg of modified conductive carbon black after complete dissolution, let the self-assembly reaction stand for 12h, vacuum The obtained powder was dried under vacuum at 60 °C for 3 h after filtration.

[0043] (2): Soak the foamed nickel substrate in hydrochloric acid, absolute ethanol, and deionized water for 15 minutes for pretreatment, and then dry it in a cool place. Weigh 170 mg of i...

Embodiment 2

[0053] Repeat the operation steps of Example 1, the difference is that in the process of preparing the AQ-C-Ni electrode, in step (1), choose g-C 3 N 4 As a carbon material, the rest are the same as in Example 1.

[0054] The electrochemical performance of the AQ-C-Ni electrode prepared under the conditions of this example is slightly higher than that of the electrode prepared under the conditions of Example 1. With respect to conductive carbon black as the carbon material, this example uses g-C 3 N 4 The AQ-C-Ni electrode prepared as a carbon material produced H at 30 min 2 o 2 1.0mg.

Embodiment 3

[0056] Repeat the operation steps of Example 1, except that in the process of preparing the AQ-C-Ni electrode, in step (2), 2-alkylanthraquinone is selected as the anthraquinone material, and the rest are the same as in Example 1.

[0057] The electrochemical performance of the AQ-C-Ni electrode prepared under the conditions of this example is slightly lower than that of the electrode prepared under the conditions of Example 1. Compared with 2-aminoanthraquinones, this example uses 2-alkylanthraquinones as The AQ-C-Ni electrode prepared by anthraquinone material produced H in 30min 2 o 2 0.5 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com