Adhesive hydrogel and preparation method thereof

A hydrogel and adhesion technology, applied in the field of polymer biomaterial preparation, can solve problems such as lack of adhesion of hydrogels, achieve enhanced adhesion effect, enhanced adhesion strength and mechanical properties, and increased adhesion force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

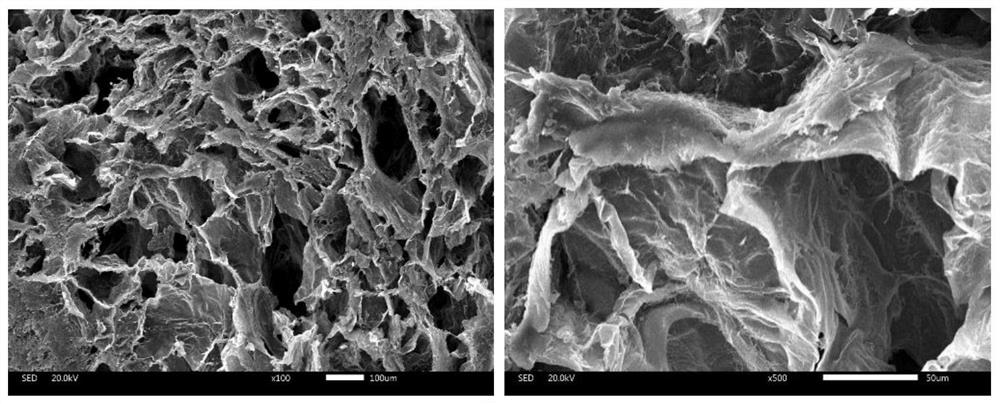

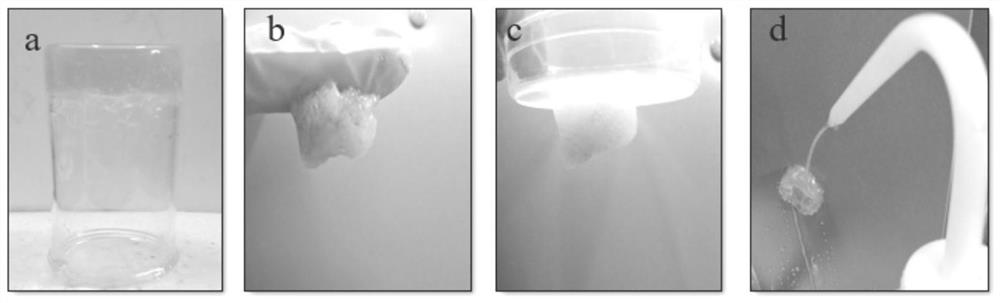

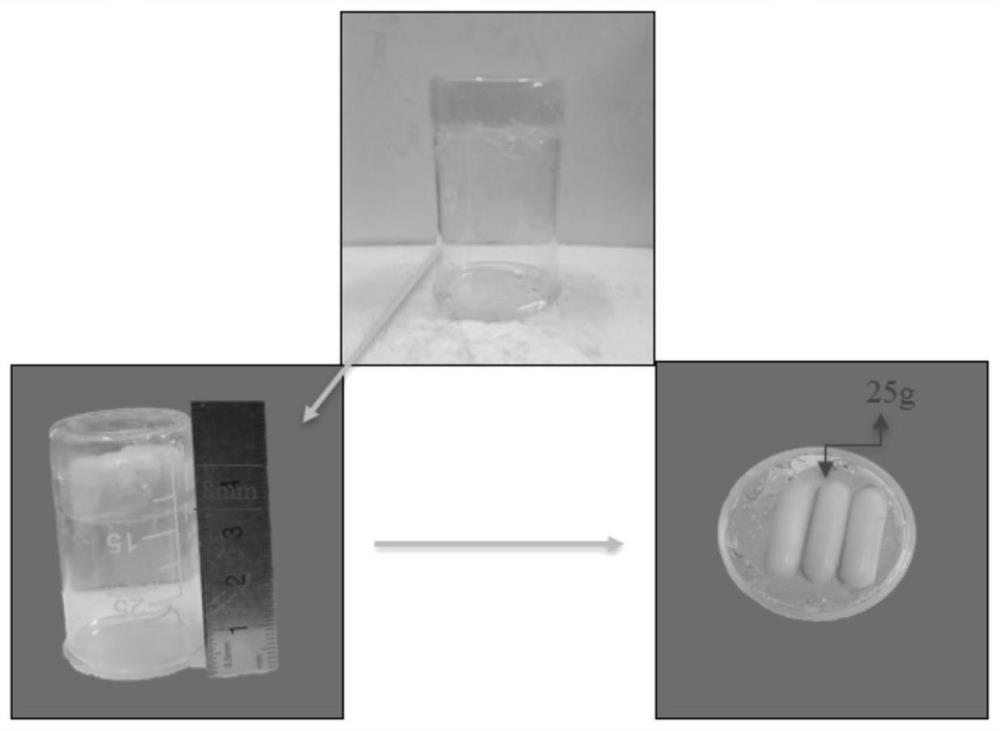

Image

Examples

preparation example Construction

[0024] This specific embodiment provides a kind of preparation method of adhesive hydrogel, comprising the following steps:

[0025] S1, according to the mass ratio of chitosan and caffeic acid 1:1-2, chitosan solution and caffeic acid solution are mixed, then dialyzed, rotary steamed, and dried to obtain modified chitosan; wherein, the caffeic acid solution Prepared by the following steps: dissolve caffeic acid in ethanol solution and stir, then add EDC according to the mass ratio of caffeic acid and EDC 1:2-2.5 to activate; the chitosan solution is prepared by the following steps: Dissolving chitosan in a glacial acetic acid solution with a pH of 3-3.5 to obtain the chitosan solution; the temperature of rotary steaming is 60-70°C;

[0026] S2. Dissolving the modified chitosan in water at 80-90°C to obtain a modified chitosan solution, and then mixing and stirring the modified chitosan solution and polyvinyl alcohol solution to obtain a hydrogel precursor ;

[0027] S3. Add...

Embodiment 1

[0033] This embodiment proposes an adhesive hydrogel, which is prepared by the following steps:

[0034] S1. Add the caffeic acid solution into the chitosan solution, protect it with nitrogen gas, avoid light for 24 hours, dialyze in a deionized aqueous solution with pH=4 for three days, perform rotary evaporation at 65°C, and dry to obtain modified chitosan , and stored in a desiccator for subsequent use; wherein, the caffeic acid solution is prepared by the following steps: 3g caffeic acid is dissolved in 300mL ethanol solution (the volume ratio of ethanol and water is 1:1) and stirred, and then added 6.5 gEDC is obtained by activating magnetic stirring for 1 h; the chitosan solution is prepared by the following steps: dissolving 6 g of chitosan in 600 mL of glacial acetic acid solution with a pH of 3 to obtain the chitosan solution; the temperature of rotary steaming is 70° C. ;

[0035] S2. Dissolving the modified chitosan in water in a water bath at 80°C to obtain a modi...

Embodiment 2

[0042] This embodiment proposes an adhesive hydrogel, which is prepared by the following steps:

[0043] S1. Add the caffeic acid solution into the chitosan solution, protect it with nitrogen gas, avoid light for 24 hours, dialyze in a deionized aqueous solution with pH=4 for three days, perform rotary evaporation at 65°C, and dry to obtain modified chitosan , and stored in a desiccator for subsequent use; wherein, the caffeic acid solution is prepared by the following steps: 3g caffeic acid is dissolved in 300mL ethanol solution (the volume ratio of ethanol and water is 1:1) and stirred, and then added 7.5 gEDC is obtained by activating magnetic stirring for 1 h; the chitosan solution is prepared by the following steps: dissolving 3 g of chitosan in 600 mL of glacial acetic acid solution with a pH of 3 to obtain the chitosan solution; the temperature of rotary steaming is 60° C. ;

[0044] S2. Dissolving the modified chitosan in water in a water bath at 90°C to obtain a modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com